Obstacles and difficulties implementing the lean philosophy in Brazilian enterprises

Caroline Morito Pereira1, Rosley Anholon1, Antonio Batocchio1

1 School of Mechanical Engineering, State University of Campinas

Abstract

The success of Lean Manufacturing does not come down only to its application tools; it is an accomplishment of the entire leadership and workers dedicated to putting the system’s essence into practice, along with its underlying values and philosophy. In this context, the main purpose of this study is to present an analytical research in terms of the obstacles and difficulties faced by Brazilian companies to implement the Lean Manufacturing. Through a literature review of the annals of ENEGEP (the Brazilian Production Engineering Conference), this research concluded that the main obstacles and difficulties of such implementation fall under seven lines: 1) difficulties using the tool; 2) operational resistance; 3) cultural differences; 4) slow response to market; 5) lack of top/senior management involvement; 6) lack of middle management support, 7) lack of resources to invest. This article stands as a useful source for further studies about the Lean Manufacturing system.

Keywords: Lean Manufacturing; Implementation Difficulties; Toyota Production System.

1 Introduction

As a result of the fast-paced globalization of the world’s economy, underlined by factors such as higher consumer demand and rising competition, the market has grown increasingly more competitive, which posed on companies the need to find quick and innovative solutions to reduce costs, increase productivity and quality (Sim et Rogers, 2008). In this scenario, organizations are more focused on achieving full customer satisfaction, and thus have been improving processes and products, eliminating waste, and applying high standards to preserve the health and safety of employees.

The surviving challenge imposed on organizations, amid a reality of dramatic competitiveness and rapid technological developments, paved the way for new management techniques which were targeted at keeping organizations competitive in an ever-changing scenario. To be actually competive in such globalized environment, organizations should innovate and put their competitive advantages at the forefront (Pereira, 2008). Therefore, conceiving agile and sufficiently strong management systems becomes essential to keep up with the standards imposed by such new economic conjuncture.

Motivated by this need, the concept of Lean Manufacturing was created as a powerful philosophy to accomplish business competitiveness. This concept combines management techniques with the reduction or elimination of waste throughout the production process, creating a more efficient production modality that requires fewer resources to be operational. This system was structured in the 1970s by the Toyota Motor Company, in Japan, interested in devising a competitive production system that could detach from the obsolete automotive industry’s parameters, hitherto characterized by the American mass production system advocated by the Ford Motor Company (Reno et al. 2001).

Although the lean philosophy has been greatly favorable to Japanese companies, few organizations outside Japan have been successful at lean implementation, facing several challenges and obstacles, which ultimately hinder their attempts (Junior et Filho, 2007). Many western organizations have been struggling to duplicate the lean system, but to no success, as they seem largely unable to maintain consistent performance and accomplish the advances that the lean philosophy promises (Argoud et al. 2004).

As an academic contribution to research about the Lean Manufacturing, and to serve as a platform to help mitigate obstacles and difficulties faced during the implementation of the lean culture in organizations, this article is targeted at tracing the main obstacles and problems faced by Brazilian companies during such implementation. Aiming such goal, this research has an underlying question, namely: what are the main obstacles and problems Brazilian companies have been encountering when implementing the Lean Manufacturing?

Based on the available literature, specifically on the works of Dal Forno et al. (2014) and Jagdish et al. (2014), this research tests out the hypothesis that the main obstacles and problems of lean implementation fall under one of the following aspects: top/senior management resistance, lack of middle management support, lack of top/senior management involvement, lack of communication between management and employees, lack of empowerment of employees, operational resistance to implementation, lack of perseverance, lack of skilled consultants and coaches, difficulties using the tool, lack of qualification for managers and employees, cultural differences, lack of cooperation and mutual trust between managers and employees, cross-functional conflicts, incompatibility between the lean manufacturing and the company’s rewards strategies, lack of resources to invest, slow response to market, poor cooperation from suppliers, quality issues regarding the materials used, absence of a strategic logistics system, lack of logistic support, issues connected to machinery and plant configuration, and lack of standardization, stability and integration of the production processes. Based on this comprehensive list, the authors of this article sought to identify which aspects were closest to the reality of the Brazilian companies tackling lean implementation.

In view of the foregoing, three secondary objectives stand out: 1) carrying out a literature review resorting to national and international databases on the subject; 2) reviewing articles on the implementation of the Lean Manufacturing over the past 14 years, and which were published in the annals of ENEGEP (the Brazilian Production Engineering Conference); 3) assessing the findings against the hypotheses raised from the literature review to ultimately identify which obstacles and problems are closest to the implementation of the lean philosophy in practice in Brazil.

2 Literature review

Toyota Production System and Lean Manufacturing

The Toyota Production System was devised in Japan in the post-World War II period and was developed by Toyota Motor Company, led by Taiishi Ohno, the visionary Vice-President of Toyota. Ohno could descry, amid the devastation undergone by Japan, an opportunity to help rebuild his country resorting to a management model that could eliminate waste and do without unnecessary production process elements in order to cut costs and compete with the Henry Ford’s mass production system. The Toyota Production System was entangled in an environment with scarce resources and intolerable waste, and thus its basic principle was to produce only the necessary, at a required time and amount (Mauricio et al. 2014).

In 1990, in the United States, the term Lean Manufacturing was created to designate the system developed by Ohno, in the book “The Machine that changed the World” by Womack, Jones and Roos. In the book, a comprehensive study about the world’s automotive industry was developed within the Massachusetts Institute of Technology, stressing the advantages of the Toyota Production System performance in view of its significant productivity, quality and product development gains, which helped explain the success of the Japanese industry (Landmann et al. 2009).

The Lean Manufacturing System aims at eliminating or reducing the so-called most common “seven wastes” in companies: overproduction, time/waiting, quality defects, unnecessary inventories, inappropriate processing, excessive transportation of goods, and unnecessary movement of people (Mauricio et al. 2014). When unnecessary activities are eliminated; all of the process stages are aligned in order to improve the continuous stream and optimize the work. This also allows companies to become more flexible and quicker in meeting the demands of customers (Turati et Musetti, 2006). All organizations should seek greater competitiveness by accomplishing five main performance goals: quality, speed, reliability, flexibility and cost, which are interconnected and bring several advantages (Sim et Rogers, 2008).

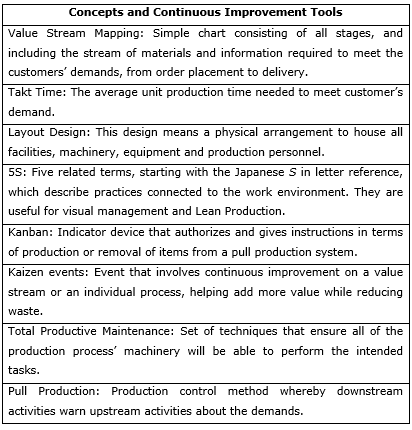

Thus, the Lean Manufacturing System is a philosophy that contributes to organizational performance, insofar as it allows companies to put their strategies into practice and, most importantly, helps boost their earnings. In Table 1, there are descriptions of some concepts and continuous improvement tools that are typically used in lean development and implementation, and can be applied when starting the organizational changes.

Table 1. Concepts and Continuous Improvement Tools

In spite of all performance advantages, there are some limitations to apply the Lean Manufacturing concepts and tools in the production processes. The Toyota Production System is not a universal system which may be applied to all types of manufacturing, not to mention the fact that there are some companies which apply the lean manufacturing practices but fail to complete the transition to the Lean Manufacturing system (Carnelossi et Cardoza, 2012). Furthermore, Hines et al. (2008) make an important remark about such matter. According to the author, one cannot speak of “universal models of administration,” or else Italian, Japanese or Swedish models; each “model” should be adjusted to a particular business and cultural situation, which should be carried out in keeping with the Lean Manufacturing philosophy.

Obstacles and Problems Faced in the Implementation of Lean Manufacturing and Definition of Limiting Hypotheses

A lean production system is quite difficult to be implemented. There are many difficulties to it on the operational and supporting framework sides and, even nowadays, they lead to a number of issues, confusion and controversies. Even in companies starting the process of lean implementation, difficulties are equally considerable (Landmann et al. 2009). Based on the research of Dal Forno (2014) and Jagdish et al. (2014), limiting hypotheses were established with regard to the obstacles and problems connected to the implementation of Lean Manufacturing, which will be checked by the research described hereunder for validity in its own context. The implementation of Lean Manufacturing is not an easy task, and there are several problems and issues reported about the difficulties encountered by companies during implementation. Only 10% or less of companies trying to implement Lean Manufacturing practices are successful in terms of understanding and applying the philosophy in their processes. Moreover, an informal survey with companies implementing lean production revealed that only 30% of them succeeded in changing the production environment, and 70% went through extreme experiences which have them quitting the philosophy and going back to their former business standards (Portioli-Staudacher et Tantardini, 2012).

To implement the Lean Manufacturing philosophy, organizations need to engage individuals from all organizational levels, including the top/senior leadership, the intermediate level and the operational level (Dal Forno et al. 2014). It is as essential that top/senior manager work based on a set of strategic guidelines and goals, which should be conducive to accomplishing the new lean system, as it is that employees be aware of the directions and changes to be implemented, which would allow all players to support and keep the process going (Portioli-Staudacher et Tantardini, 2012).

In order to achieve success in any change inside an organization, it is necessary that individuals and processes be integrated, and that awareness of procedures and the general understanding of tools be ensured, especially in the cases of low-skilled staff (Dal Forno et al. 2014), thus, not running the risk of hindering the implementation. The resistance forces or obstacles need to be identified and understood (Portioli-Staudacher et Tantardini, 2012). The lack of access to the organizational changes being implemented may lead to resistances and poses many risks, ultimately bringing about the need for much more time and energy during the process.

In view of the foregoing, the limiting hypotheses to this research could be drawn out of the aspects refered to above, and a thorough review of the works mentioned.

Limiting hypotheses: the main obstacles and problems connected to the implementation of Lean Manufacturing revolve around the following topics: top/senior management resistance, lack of middle management support, lack of top/senior management involvement, lack of communication between management and employees, lack of empowerment of employees, operational resistance to implementation, lack of perseverance, lack of skilled consultants and coaches, difficulties using the tool, lack of qualification for managers and employees, cultural differences, lack of cooperation and mutual trust between managers and employees, cross-functional conflicts, incompatibilities between the lean system and the company’s rewards strategy, lack of resources to invest, slow response to market, lack of cooperation from suppliers, quality issues regarding the materials used, absence of a strategic logistics system, lack of logistic support, issues connected to machinery and plant configuration, and lack of standardization, stability and integration of the production processes.

3 Methodological Procedures

Research Aspects

Initially, the research was classified, as presented hereunder. As far as its overall method is concerned, this research may be classified as a deductive approach research, insofar as it allows drawing conclusions from true premises (Gil, 2010).

With regard to the way how it addresses the problem, this research is qualitative, since it entails the interpretation of scientific papers and pursues an overview out of literature review. Qualitative research is often oriented, throughout its development, and does not seek either to itemize or measure events. Typically, qualitative research does not employ statistical instruments for data analysis and attempts to understand and interpret the phenomena from the participants’ perspective in each study situation (Gil, 2010). In turn, relating to its technical procedures, this research may be classified as a bibliographic research. Bibliographic research is targeted at explaining, by means of a theoretical structure, one problem addressed in the published literature (Gil, 2010). The bibliographic research consists of gathering and analyzing the former contributions on a particular subject. This research is relevant due to identifying and following the research development in a given area of knowledge, thus allowing a comprehensive coverage of the studied phenomena (Gil, 2010). Moreover, perspectives for future research may arise from bibliographic research, contributing to the development of new research projects.

Lastly, with respect to the nature of this research, it may be classified as applied and exploratory, since it focuses on assessing the application of a particular approach (difficulties implementing the Lean Manufacturing) to solve business problems. Applied research focuses on improving the knowledge regarding the issue addressed, enlightening on it, or else coming up with hypotheses about it (Ganga, 2012). It involves bibliographic survey, interviews with practitioners and the analysis of examples that further the understanding on the matter at hand. Furthermore, the purpose of applied research is to broaden the knowledge connected to practical applications, with the aim of solving specific problems involving the truths on the issue and local interests (Gil, 2010).

Method

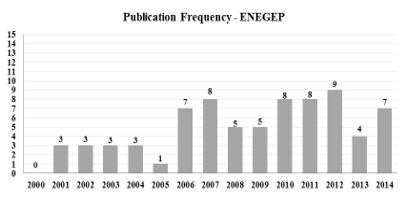

The first stage of the research was to spot the obstacles encountered by companies to implement the Lean Manufacturing philosophy based on a review of the ENEGEP’s database. This database was chosen because ENEGEP is the largest Production Engineering event held in Brazil. The research was carried out using expressions with the following keywords: Lean Manufacturing, difficulties implementing Lean Manufacturing and Toyota Production System. Only articles published from 2000 to 2014 were considered, aiming to produce content and devising the associated concepts for the last 14 years. Figure 1 illustrates the frequency of articles on the subject according to the year of publication. It should be noted that, in 2000, no article was published about the subject of this research.

The second stage consisted in analyzing and ranking the results obtained from the database in accordance with the relevance criterion (relevance increases when the term is present in titles, followed by keywords and abstracts). The analysis was limited to the first 74 results of each expression searched. Articles were read and analyzed according to their correlation to the researched topic, which resulted in a selection of 68 articles. During this analysis, the main obstacles and problems connected to the implementation of Lean Manufacturing could be identified for the companies studied.

Figure 1. Number of papers published in ENEGEP about Lean Manufacturing from 2000 to 2014

At the third stage, the main obstacles and problems were divided into groups, according to the similarity of given aspects. Thus, seven major strata were delineated to show results, and they are: 1) difficulties using the tool; 2) operational resistance; 3) cultural differences; 4) slow response to market; 5) lack of top/senior management involvement; 6) lack of middle management support; 7) lack of resources to invest. These limiting hypotheses were addressed through the medium of international literature, and were substantiated accordingly. Finally, the fourth and final stage consisted in the drafting of this article, the final object of the research.

4 Findings

Researched Articles

During the articles review, attention was geared towards the type of research conducted in each work and the tools and mostly applied concepts connected to the implementation of the Lean Manufacturing philosophy shown by their authors. This data could be spotted based on the characteristics of articles on the same topic of this paper.

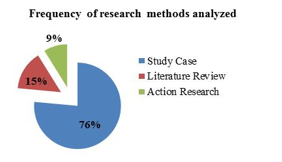

Figure 2 illustrates the type of research developed in each article studied. More than half of them (76%) were essentially study cases, while 15% of the articles resorted to literature review. Furthermore, it should be noted that the research methodology classified as action research represented only 9% of the papers reviewed.

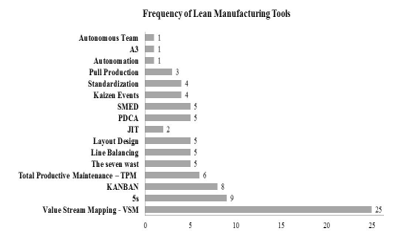

With regard to the Lean Manufacturing tools/concepts studied, Figure 3 illustrates the amount of articles of each type. The Value Stream Mapping (VSM) is the tool/concept with the largest number of studies published (25 papers), followed by 09 studies that address the use of the 5S program.

Figure 2. Frequency of research methods applied by the articles reviewed

Figure 3. Frequency of Lean Manufacturing tools addresses by in the articles reviewed

Obstacles and Problems in the Implementation of Lean Manufacturing by Brazilian companies

Based on the literature review, a set of twelve obstacles and problems connected to the implementation of Lean Manufacturing was spotted. These obstacles and problems were referred to by the thirty-six articles reviewed.

Considering that, in many papers, there were different expressions to describe the same issue; the final set may be reduced to seven major categories after crossing similarities and dissimilarities. The works of Camagu (2010) and Arbulu et Tommelein (2002) may be cited as examples of this occurrence. While Camagu (2010) mentions the difficulties faced by workers in fully following the new method due to already being accustomed to the previous system; Arbulu et Tommelein (2002) mention the need for a cultural change to help all individuals align with the new methodology implemented in order to achieve success. In brief, both authors present the same type of obstacle and problem in their papers.

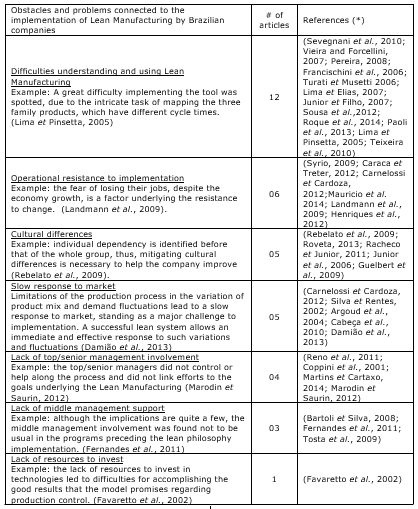

Table 2 presents the seven umbrella categories under which the articles may be placed. For each category, articles are presented according to the obstacle and/or problem to which they refer, and statements extracted from such articles to exemplify and define each category. It should be emphasized that the articles reviewed do not address obstacles and problems such as natural disasters, general strikes or changes to applicable laws. Such issues were raised by Marchwinski et Sook (2001) in their work.

Table 2. Categories, examples e amount of articles addressing obstacles and problems connected to the implementation of Lean Manufacturing by Brazilian companies.

5 Discussion of Findigs

As mentioned, the main purpose of this article is to survey the obstacles and problems underlying the implementation of Lean Manufacturing in companies as a way of portraying the Brazilian reality with regard to the application of such philosophy. After the literature and article review, seven potential obstacles and risks that may lead to failure in the implementation of the Lean Manufacturing philosophy were identified. Each obstacle or problem was briefly exemplified above. In this topic, correlations will be exposed in connection with the limiting hypotheses for each category identified.

a) Factor 1: Difficulties Understanding and Using Lean Manufacturing

The factor which was mostly referred to in the articles reviewed is the difficulty understanding and using Lean Manufacturing, accounting for twelve articles. Flaws in the measurement of production process data and inconsistent data which do not represent the true reality in terms of the process result in the misapplication of Lean Manufacturing philosophy (Aurelio et al., 2011). Workers and managers’ difficulty understanding the concept leads to misapplication and may imply the non-achievement of plausible improvements as a consequence.

Consequently, before starting to implement the Lean Manufacturing within the company, different sorts of training are necessary for white-collar managers, as well as for blue-collar workers (Hines et al., 2008). The lack of a clear training script, as well as mapping skills, may be seen as traps that bring difficulties to the improvement process (Hines et al., 2008).

b) Factor 2: Operational Resistance to Implementation

The second mostly referred factor in the articles reviewed was the operational resistance to the implementation of the Lean Manufacturing philosophy in processes. As the Lean production methodology deals with the elimination of activities which do not add value to the company, workers’ resistance may be connected to the “aspect of fear” of losing their jobs, since their activities may be evaluated as not adding value to the process (Vieira et Forcellini, 2007). The potential reduction of staff stands as a major factor for the reluctance of many workers (Belova et Yansong, 2015).

The lack of workers’ transparency and cooperation directly affects Lean Manufacturing and, most often, frustrates its implementation and success. This attitude typically weakens the individuals’ willing to participate in the activities, since the improvement pace decreases and ultimately leads businesses to return to the former way of working their processes (Cabeça et al., 2010).

c) Factor 3: Cultural Differences

The third mostly referred factor by the articles reviewed lies in the cultural differences identified in companies which have implemented the philosophy. The cultural issues identified during the implementation of the lean production have ethnical, organizational and professional origins (Junior et Filho, 2007). A common obstacle to Lean Manufacturing initiatives is the inability to create a culture of improvement due to cultural and linguistic factors, bringing on challenges to the implementation of techniques and to the workforce participation (Coppini et al., 2011).

d) Factor 4: Slow Response to Market

The fourth factor comes from the slow market response in companies that produce a wide array of products. The comprehensive product portfolio of companies, smaller production batches and demand fluctuations increase the complexity and need for better production organization. These aspects often cause the lean manufacturing techniques to work for one type of product, but not for all. In several instances, they may increase waste in production (Bartoli et Silva, 2008).

The need for the market to quickly respond to changes in the portfolio of product, impose obstacles to the implementation of Lean Manufacturing, since changes in the designs of products, rescheduling of customers and the inability to keep schedules lead to slow responses to market, one aspect that diverges from the lean production philosophy, which allows an immediate and effective response to demand fluctuations and market requirements (Coppini et al., 2011).

e) Factor 5: Lack of top/senior Management Involvement

The fifth factor is the lack of top/senior management involvement during the implementation of the Lean Manufacturing methodology. The lack of top/senior management understanding and support are critical factors that bring about difficulties in supporting the lean production concept (Teixeira et al., 2010). The lack of commitment, prioritizing actions other than those involving the implementation of Lean Manufacturing, may bring on a number of problems, including limited access to resources, long decision-making processes and communication failures (Vieira et Forcellini, 2007).

In order to create a real transformation by lean production, a strong leadership should take the forefront within the organization, and this should include executive officers to support not only intellectually, but also physically the whole process (Teixeira et al., 2010).

f) Factor 6: Lack of middle Management Support

The sixth factor is the lack of middle management support to the implementation of Lean Manufacturing. Managers lead to difficulties by assigning activities, increasing the scope of the workers’ decisions, not reserving time to help with doubts and hindering the establishment of a strong cooperation and mutual trust between the management and employees. Often times they tend to belittle the practices and benefits from the lean production implementation (Paoli et al., 2013). According to Silva et Rentes (2002), the lack of commitment of the management stands as a major obstacle to the success of Lean Manufacturing, which relies on a transparent environment between the management and operation sides, which should work in concert to ensure the preset strategies and goals (Henriques et al., 2012).

g) Factor 7: Lack of Resources to Invest

The seventh and final factor it is the lack of resources to invest, which some companies have to face and it stands as an obstacle to the implementation of Lean Manufacturing. Such companies state that they do not have time or money to spend on training their employees or to invest in lean production programs (Teixeira et al., 2010). According to Damião et al. (2013), the costs connected to the time required for training and appropriately implementing Lean Manufacturing are common obstacles in some companies. A typical belief is that specialized consultants need to be hired to successfully implement the system.

6 Conclusion

As previously mentioned, this article is targeted at analyzing the obstacles and problems associated to the implementation of Lean Manufacturing by Brazilian companies, assessing information collected vis-à-vis the limiting hypotheses, which were grounded on the available literature.

Based on the findings from the review of articles published over the past 14 years about Lean Manufacturing at the main event of Production Engineering in Brazil, ENEGEP, the research problem could be better explained, and seven out of the twenty-five limiting hypotheses available in the literature could be substantiated. Obstacles and problems underlying the implementation of the Lean Manufacturing philosophy by Brazilian companies that may lead to failure are: difficulties understanding and using Lean Manufacturing, operational resistance, cultural differences, slow response to market, lack of top/senior management involvement, lack of middle management support and lack of resources to invest.

The increasing number of articles being published on the use of Lean Manufacturing underlines that lean production is a prominent issue. However, it should be noted that not always a Lean Manufacturing tool/concept applied in a company will have the similar results in another company with the same size or conducting business in the same niche. This can be explained by the different obstacles and risks faced by each organization.

Some limitations to this article should be noticed. Although this is a literature review, some criteria depend on the researchers’ choice, such as, for example, the definition of the term to be used when searching databases. Therefore, one cannot ensure that all relevant articles on the matter will be present in this review. In this vein, a more comprehensive identification of studies, for example, all of the studies in the database could result in different findings. Furthermore, a wide array of articles that addressed VSM as a Lean Manufacturing tool in their research lead to a major limitation, with respect to the diversity of study scenarios. This article contributed to academic research on the Lean Manufacturing and can be used as a resource for further studies. Accordingly, it may be seen as a launching pad for the development of strategies to overcome obstacles during the implementation of Lean Manufacturing, helping companies to successfully implement the tool.

References

Arbulu, J. Tommelein, I. (2002). VSA of construction supply chains: case study on pipe supports used in power plants. Proceedings IGLC-10. Gramado, Brasil.

Argoud, A. Cardoza, E. Fortulan, M. Filho, E. (2004). Aplicação dos conceitos de produção enxuta em um ambiente de alta diversidade de produtos e demanda variável: um estudo de caso. XXIV Encontro Nacional de Engenharia de Produção. Florianópolis, Brasil.

Aurelio, D. Grilo, A. Cruz-Machado, V. (2011). A framework for evaluating lean implementation appropriateness. Proceedings of International Conference on Industrial Engineering and Engineering Management. Singapore, Malasia.

Bartoli, I., Silva. M. (2008). Lean Manufacturing voltado para a indústria siderúrgica MTO. XXVIII Encontro Nacional de Engenharia de Produção. Rio de Janeiro, Brasil.

Belova, I., Yansong, Z. (2008). Value stream mapping for waste reduction in playing system components flow. Retrieved in 2015. URL: http://www.divaportal.org/smash/get/diva2:3609

Cabeça, M. Silva, I. Benevides, G. (2010). Análise comparativa do uso das ferramentas de gestão Lean Manufacturing e Seis Sigma: um estudo de caso. XXX Encontro Nacional de Engenharia de Produção. São Carlos, Brasil.

Camagu. S. (2010). Investigating factors that negatively influence lean implementation in the eastern cape automotive industry. Retrieved in 2015. URL: http://www.nmmu.ac.za

Carnelossi, A. Cardoza. E. (2012). Proposta de melhoria para o processo produtivo de uma indústria de envase de óleo vegetal. XXXII Encontro Nacional de Engenharia de Produção. Bento Gonçalves, Brasil.

Coppini, N. Baptista, E. Junior, M. Bekesas, L. (2011). Mapeamento do fluxo de valor aplicado na implantação do ERP na cadeia de suprimentos de uma empresa do setor metal mecânica. XXXI Encontro Nacional de Engenharia de Produção. Belo Horizonte, Brasil.

Dal Forno, A. Pereira, F. Forcellini, F. Kipper, L. (2014). Value Stream Mapping: a study about the problems and challenges found in the literature from the past 15 years about application of Lean tools. International Journal Advanced Manufacturing Technology. Vol. 72, pp. 779-790. Retrieved from http://dx.doi.org/10.1007/s00170-014-5712-z

Damião, M. Denipote, V. Rabechini, M. Albertos, T. (2013). Lean Manufacturing: uma discussão sobre sua adaptação em empresas dos ramos automobilísticos e alimentício. XXXII Encontro Nacional de Engenharia de Produção. Salvador, Brasil.

Favaretto, F. Martins, V. Bremer C. (2002). Considerações sobre a utilização de dados de controle da produção no contexto da filosofia lean production. XXII Encontro Nacional de Engenharia de Produção. Curitiba, Brasil.

Fernandes J. Pereira, A. Dionizio, A. Nereu, M. Marques M. (2011). Análise da viabilidade técnica para a implantação do lean manufacturing em uma planta piloto de testes em refratários. XXXI Encontro Nacional de Engenharia de Produção. Belo Horizonte, Brasil.

Francischini, P. Miyake, D. Giannini, R. (2006) Adaptação de conceitos de melhorias operacionais provenientes do Lean Production em operações de serviços. XXVI Encontro Nacional de Engenharia de Produção. Fortaleza, Brasil.

Ganga, G. (2012) Trabalho de conclusão de curso na Engenharia de Produção: um guia prático de conteúdo e forma. Atlas. São Paulo.

Gil, A. (2010). Como elaborar projetos de pesquisa. Atlas. São Paulo.

Guelbert, M. Merino, E. Leszczynski, C. Guerra, J. (2009) Gestão estratégica de manufatura para medias empresas. XXIX Encontro Nacional de Engenharia de Produção. Salvador, Brasil.

Henriques, F. Santos, A. Macedo, M. (2012). Análise do mapeamento do fluxo de valor na identificação de desperdícios na logística interna: um estudo de caso na indústria têxtil. XXXII Encontro Nacional de Engenharia de Produção. Bento Gonçalves, Brasil.

Hines, P. Found, P. Griffiths, G. Harrison. R. (2008). Staying Lean: Thriving, not Just Surviving. Lean Enterprise Research Centre. Cardiff, Wales.

Jagdish, R. Shankar, S. Santosh. B. (2015). Exploring barriers in lean implementation. International Journal of Lean Six Sigma.Vol. 5. Nº 2, pp. 122-148. 2014. URL: http://dx.doi.org/10.1108/IJLSS-12-2012-0014

Junior, J. Cardoso, A. Chaves. C. (2006). A utilização da filosofia da manufatura enxuta aplicada em uma área de montagem de mangueiras de ar condicionado. XXVI Encontro Nacional de Engenharia de Produção. Fortaleza, Brasil.

Junior, M. Filho. M. (2007). A utilização do Sistema Kanban em empresas do estado de São Paulo: estudo por meio de um survey. XXVII Encontro Nacional de Engenharia de Produção. Foz do Iguaçu, Brasil.

Landmann, R. Bittencourt, E. Schwitzky. M. (2009). Lean office: aplicação da mentalidade enxuta em processos administrativos de uma empresa do setor metal-mecânico. XXIX Encontro Nacional de Engenharia de Produção. Salvador, Brasil.

Lima, A. Pinsetta. W. (2005). Mapeamento da cadeia de valor na divisão de suprimento do hospital de clínicas da UNICAMP para redução do lead time no processo de aquisição de materiais hospitalares. XXV Encontro Nacional de Engenharia de Produção. Porto Alegre, Brasil.

Lima, C. Elias. S. (2007). Análise dos resultados da implantação da produção enxuta nas organizações: um estudo a partir dos casos relatados no ENEGEP. XXVII Encontro Nacional de Engenharia de Produção. Foz do Iguaçu, Brasil.

M. Martins, G. Cartaxo. (2014). Análise da viabilidade de melhoria produtiva a partir da aplicação da manufatura enxuta na indústria de confecções. XXXIV Encontro Nacional de Engenharia de Produção. Curitiba, Brasil.

Marchwinski, C. Shook. J. (2011). Léxico Lean. The Lean Institute Brasil.São Paulo.

Marodin, G. Saurin. T. (2012). Linhas de pesquisa em implantação de sistemas de produção enxuta de 2000 a 2012: uma revisão da literatura”. XXXII Encontro Nacional de Engenharia de Produção. Bento Gonçalves, Brasil.

Marodin. G. (2012). Identificação de riscos na implantação da produção enxuta: um estudo de caso em uma empresa automotiva”. XXXII Encontro Nacional de Engenharia de Produção. Bento Gonçalves, Brasil.

Mauricio, F. Leal, V. Sousa. (2014). Implementação do SMED em uma empresa de autopeças: um caso francês. XXXIV Encontro Nacional de Engenharia de Produção. Curitiba, Brasil.

Ohno, T. (1997). O Sistema Toyota de Produção – além da produção em larga escala. Artes Médicas. Porto Alegre.

Paoli, F. Junior, M. Lucato, W. (2013). Conceitos de manufatura enxuta aplicados a um processo de usinagem de peças de grande porte: um estudo de caso. XXXII Encontro Nacional de Engenharia de Produção. Salvador, Brasil.

Pereira. M. (2008). Estudo de caso da metodologia SMED: questões operacionais para implantação em tornos CNC. XXVIII Encontro Nacional de Engenharia de Produção. Rio de Janeiro, Brasil.

Portioli-Staudacher, A. Tantardini, M. (2012). Investigating the main problems in implementing Lean in supply chains of service companies. International Journal of Services and Operations Management.Vol. 11. Nº 1, pp. 87-106.

Rebelato, M. Rodrigues, A. Rodrigues, I. (2009). Análise das lacunas presentes na integração da manufatura enxuta com a metodologia seis sigma. XXIX Encontro Nacional de Engenharia de Produção. Salvador, Brasil.

Reno, G. Diniz, C. Yamaguti, H. Silva. D. (2011). Jogo de negócio simulador dos efeitos positivos da aplicação das ferramentas lean para funcionários operacionais e lideranças do chão de fábrica. XXXI Encontro Nacional de Engenharia de Produção. Belo Horizonte, Brasil.

Roque, Y. Freitas, W. Filho, P. Silva, M. (2014). Utilização do relatório A3 como técnica de prevenção e solução de problemas em uma indústria norte mineira. XXXIV Encontro Nacional de Engenharia de Produção. Curitiba, Brasil.

Roveta, M. (2013). O programa lean seis sigma: uma visão plena de uma empresa do setor de mineração. XXXII Encontro Nacional de Engenharia de Produção. Salvador, Brasil.

Sevegnani, G. Barkenbrock, T. Renó, G. Truzzi, O. Diniz, C. (2010). A necessidade do envolvimento dos trabalhadores para aderência de padrões de trabalho obtidos com o Lean Manufacturing. XXX Encontro Nacional de Engenharia de Produção, São Carlos, Brasil.

Silva, A. Rentes, A. (2002). Tornando o layout enxuto com base no conceito de mini-fábricas num ambiente de multiprodutos: um estudo de caso. XXII Encontro Nacional de Engenharia de Produção. Curitiba, Brasil.

Sim, K. Rogers, J. (2008). Implementing lean production systems: barriers to change. Management Research News. Vol. 32. Nº 1, pp. 37-49.

Sousa, D. Silveira, L. Bagno, R. (2012). Aplicabilidade dos princípios do lean manufacturing no setor de serviços: estudo em uma oficina mecânica de motos. XXXII Encontro Nacional de Engenharia de Produção. Bento Gonçalves, Brasil.

Syrio, F. (2009). Proposta de um método para priorização de projetos Kaizen na implementação do lean manufacturing: aplicação na indústria aeronáutica. XXIX Encontro Nacional de Engenharia de Produção, Salvador, Brasil.

Teixeira, R. Elias, S. Tubino D. (2010). Análise e propostas de melhoria do processo produtivo através do mapeamento do fluxo de valor. XXX Encontro Nacional de Engenharia de Produção. São Carlos, Brasil.

Tosta, L. Oliveira, M. Souza, L. (2009). Uma análise do uso da técnica mapo fluxograma na implementação inicial do Sistema lean de produção em uma empresa do setor médico cirúrgico. XXIX Encontro Nacional de Engenharia de Produção. Salvador, Brasil.

Turati, R. Musetti, M. (2006). Aplicação dos conceitos de Lean Office no setor administrativo público. XXVI Encontro Nacional de Engenharia de Produção. Fortaleza, Brasil.

Vieira, C. Forcellini, F. (2007). Mapeamento do fluxo de valor na fase de planejamento do processo de desenvolvimento de produtos”. XXVII ENEGEP. Foz do Iguaçu, Brasil.

Womack, J. Jones, D. (2004). A máquina que mudou o mundo. Campus. São Paulo.