Bezmialem Vakif University, İstanbul, Turkey

Faculty of Administrative Sciences, Istanbul University, İstanbul, Turkey

Goal: This paper aims to demonstrate the mediating effect of internal integration in the relationship between long-term connections with customers/suppliers and operating performance. Businesses that want to improve operating performance often try to establish long-term relationships with customers and suppliers. However, at this stage, they neglect the internal integration process.

Design/Methodology/Approach: Exploratory and empirical data were collected from Turkey's largest 500 manufacturing firms. Factor analyses were performed to verify thevalidity and reliability of the data set and scales. Then, the relationships between the variables were tested with a hierarchical regression model.

Results: The findings show that the internal integration variable has a full mediating effect on the relationship between long-term relationships with customers/suppliers and the operating performance variable.

Limitations of the investigation: This research is based only on large industrial enterprises, and the results can only be interpreted in the context of emerging economies.

Practical implications: When businesses try to establish long-term relationships with customers and suppliers, they often neglect the internal integration process, making the long-term relationship processes ineffective. This research focuses on internal integration and emphasizes its impact on the relationship between variables.

Originality/Value: This study on the integration of supply in the context of Turkey's largest production company is the first and original research. These results for manufacturing enterprises in developing countries with a similar economic structure to Turkey are expected to provide practical benefits.

Keywords: Supply networks; Long-term relationship; Internal integration; Hierarchical regression model

The supply network management process is intended to discover what participants think about the interactions within the network. It is necessary to define the relationships of the participants with their customers or their suppliers and also to reflect the behaviors that support the establishment of close relations between buyers and sellers.

Two critical issues affect the development of these relationships. First, participants want to establish and develop more long-term relationships. Secondly, participants emphasize the importance of the communication process within the supply network. There should be a high level of communication between the participants in the supply network, as well as high-level contacts between commercial parties. Participants should share trust and honesty with each other (Spekman et al., 1998).

Within the framework, long-term relationships with customers and suppliers are expected to improve the performance of the enterprise. Business performance evaluation includes the customer base, finances and operational issues. These issues include metrics such as quality, cost, market share, supply and order time reduction (Mbugua and Namada, 2019).

Businesses that want to improve their performance need to develop close relationships with their customers and suppliers. In this context, external integration focuses on establishing a good connection with customers and suppliers (Aula et al., 2018). In addition, network enterprises aiming to provide customers with high quality at minimum costs and in the shortest period of time should rationally supply and use the material (Swafford et al., 2008). However, only long-term relationship development may not be efficient. The object of maintaining these relationships to be strong and close is to create pressure to establish logistic integration in the internal processes of the enterprise.

Therefore, enterprises perform logistic integration within the network. Logistics integration can be defined as the tactical level of information exchange within the supply network. Inventory levels, production planning, and operating procedures can be shown as information types at the tactical level. Because this information can be easily transferred, it can be characterized as explicit rather than implicit information. For this reason, logistic integration can be expressed as a high degree of frequent and clear information exchange. High levels of logistics integration show the flexibility of material management, especially when faced with unexpected events (Vachon and Klassen, 2007). According to Koçoğlu et al., (2011) integration improves knowledge sharing through trust-based relationships.

Internal logistics can be viewed from two perspectives. First, there are activities related to functions with direct control (Order management and information management, transportation, facilities, order quantity, and inventory costs). The second are the functions that have indirect control or influence on traditional business activities. Effective business is the management of resource transformation. Therefore, while total costs are minimized, customer satisfaction should be ensured and sufficient value should be created (Gattorna and Walters, 1996).

According to Handfield and Nichols (1999), the internal supply chain is the activities in the single organization of the supply chain. Moreover, the internal supply chain can be very complex. In particular, for multidivisional and multinational businesses, it is not uncommon for the internal part of a supply chain to have multiple connections.

Developing an internal supply chain understanding is often a suitable starting point for companies that consider a supply network initiative. In these multidivisional enterprises, it is interesting that employees in one part of the enterprise are seen as external suppliers or customers by other departments. In some cases, turf wars within the company hinder the integration of functions and processes between departments (Handfield and Nichols Jr., 1999). In this context, internal integration can be defined as the integration of business functions within the boundaries of the enterprise. The purpose of internal integration is to develop a process-oriented structure. However, internal integration focuses on coordination between business functions. In this way, logistic activities’ interaction with the functions in the enterprise can be examined. In this respect, integration shows how different departments of an enterprise work together in harmony and effective coordination (Richey et al., 2010).

In addition, internal integration means that an enterprise can configure its organizational strategies, applications, procedures and behaviors into collaborative, synchronized and manageable processes to meet customer needs. (Zailani et al., 2019; Vankireddy and Baral, 2019). Therefore, internal integration has a critical importance, especially in the performance of industrial enterprises operating in international markets. Accordingly, Errassafi et al. (2019) state that internal integration has a positive effect on operational performance; similarly, Hamali et al. (2019) state that internal information integration has a positive effect on customer satisfaction, financial performance, and supply chain performance.

In addition, integration and socialization are closely related. Socialization is a mechanism that enables integration to take place effectively — it is among the internal socialization mechanisms, such as establishing cross-functional teams, changing personnel among projects, participating in kaizen workshops, team-building exercises, facilitating internal communication and structuring internal relations that help support external activities (Cousins and Menguc, 2006). Therefore, internal integration positively affects companies’ financial performance, market share and time-based performance. In this theoretical context, one of the aims of the research is to ascertain the conditions that affect the connection between the long-term relationships with customers and suppliers and the performance of the industrial enterprise, and, in particular, whether internal integration has a mediating effect on the connection, and if so, examining the direction and strength of this effect. In this way, it can be stated that another purpose is to expand the knowledge pool of the relevant literature and to provide an alternative explanation to the results of the studies carried out. In this way, the intention is to make theoretical and practical suggestions to researchers and industry practitioners.

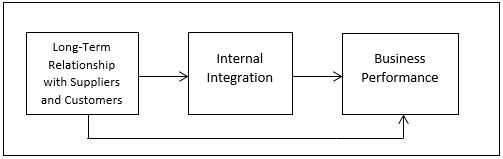

The goal of business management is to improve business performance. This will reduce costs and increase profitability at the same time. To this end, the enterprises obtain quantity discounts through long-term contracts with their suppliers and at the same time ensure the supply of quality raw materials. Businesses also want to sell their goods quickly to obtain cash, so they strive to increase customer value by establishing long-term relationships with their customers. Thus, they guarantee their present and future incomes. However, for a successful long-term relationship with both suppliers and customers, all functions within the enterprise must be firmly integrated. If there is no internal integration, the flow between suppliers and customers is neglected. In this context, a successful long-term relationship development strategy depends on the integration of business functions. In this direction, the conceptual framework of the study is shown in Figure 1.

Figure 1. The research model

However, the research model appears to be critical for the business models of multinational companies. Demeter et al. (2016) stated that information sharing, especially for multinational companies, is necessary in order to cooperate with other units within the supply network. In this context, in order to receive information within the network on a global basis, an affiliate must integrate internally, with frequent and intense interactions, with other affiliates, and establish close links with other network units. Moreover, the high performance of enterprises in the global economy depends on their capacity to process information. In this respect, integration provides routines and rules to coordinate and control the flow of information and improve the firm's computing capability (Shou et al., 2018). Therefore, the research model tests the reasons that affect the development of these rules. Among these reasons, trust between business and network participants is critical (Capaldo and Giannoccaro, 2015). This trust depends on establishing a long-term relationship with suppliers and customers. Both local and global supply networks have almost the same structural character. Even if differences exist on a cultural basis, global business norms prevent major deviations. Mentzer et. al. (2001) demonstrate that the success of supplier relations depends on the participants' focus on common goals and policies. This objective and policy integration is the key success criterion in supply networks. In fact, long-term relationships with network participants force companies to realize internal integration. Within the scope of the research model, integration and long-term relationships need to be explained.

Mackelprang et al. (2014) examined the impact of strategic supply chain integration on the business performance of enterprises. The authors discussed internal integration, customer integration, and supplier integration as subdimensions of supply chain integration. Several other studies also established subdimensions of supply chain integration. Alexandru (2014) describes the main integration areas affecting the performance of enterprises within the supply chain; internal operations, customers, suppliers, technology planning, and measurement standards are expressed. Koufteros et al. (2014), in their research on the effects of internal and external integration levels of organizations on organizational structure, have divided the integration dimensions of enterprises into four subdimensions: internal integration, customer integration, supplier integration, and horizontal integration. Kim (2013), Lofti et. al. (2013), Afshan (2013), and Han et. al. (2013) established three subdivisions for supply chain integration: internal integration, customer integration, and supplier integration.

Droge et al. (2012) examined the effect of external supply chain integration on the mediation between product/process strategies and service performance. In this study, the authors defined the external integration variables within the enterprise's supply chain as customer integration and supplier integration and did not consider the internal integration variable in their research. Wolf (2011) conducted research on sustainable supply chain integration. The subdimensions discussed in the study for supply chain integration are internal integration, external forward integration, and external backward integration. In addition, the author identified external forward integration as customer integration, and external backward integration as supplier integration. Flynn et al. (2010), in their research on the effect of supply chain integration on operational performance, examined the integration subdimensions as internal integration, customer integration, and supplier integration. Chang (2009), in the study that evaluates the supply chain integration with a balanced scorecard, examined the subdimensions of supply chain integration as internal integration, customer integration, supplier integration, technology and planning integration, relationship integration, and measurement integration.

Swink et al. (2007) examined the effect of four types of integration on factory performance — strategic customer integration, strategic supplier integration, product-process technology integration, and corporate strategy integration. Kim (2006) researched the impact of supply chain management on the enterprise's integration and competitiveness capabilities. Integration dimensions are blended into three subdimensions: integration of the enterprise with suppliers, integration within the enterprise, and integration with the customers. Campbell and Sankaran (2004) have crafted an inductive framework for an extended supply chain integration. The subdimensions of supply chain integration are defined as internal integration, forward integration, and backward integration. The authors described forward integration as customer integration, and backward integration as supplier integration in their study.

Today, the way businesses interact with suppliers is changing. In particular, information technologies and other electronic tools help businesses offer differentiated services to their customers, including higher quality, flexible delivery dates, and private offers to individual customers (Silva and Oliveira, 2017). The fact that production enterprises are much more focused on their core capabilities increases their dependence on strategic suppliers. This has led to three fundamental changes between production enterprises and suppliers. First, enterprises prefer to establish and maintain long-term relationships over short-term contracts with their suppliers. Second, businesses want to work with fewer suppliers, rather than with a broad supplier base, where they often make contract changes. While low prices resulted in intense competition among the suppliers, the reductions in the amount of purchases brought by the high amount of purchases now reduce the costs of the enterprises. Third, enterprises develop strategic relations at the strategic level as an integral part of the company's internal processes (Prajogo and Olhager, 2012).

Many researchers have evaluated the importance of long-term business relationships. Cannon et al. (2010) pointed out the importance of the long-term relationship variable for the development of mutual trust and responsibility. Ryu et al. (2007) examined the contribution of the establishment of trust between the enterprise and its suppliers to long-term orientation in their research. Wang et al. (2015) emphasized the role of long-term orientation in achieving satisfaction and trust in relations between enterprises. Prajogo and Olhager (2012) stated that the long-term relationship with the suppliers will have a positive effect on the information integration of the enterprises within the supply chain. However, in these studies the customer dimension of a long-term relationship has been neglected.

In rare academic studies on the subject in Turkey, the integration of the supply network is discussed only in terms of the integration of the business of information technology (Yörükoğlu et al., 2014; Özdemir and Doğan, 2010; Yüksel, 2002). The supply network is separated into components, and research is conducted in conjunction with the internal integration of business performance, something that was not previously performed in Turkey. At the same time, as the supply network integration reveals problems in addressing the lack of a long-term relationship with the size of the research, the study reveals the importance of Turkey.

Therefore, the research will be tested on the supply network integration of the top 500 organizations engaged in Turkey's production of the conceptual model framework set forth above using internal integration with statistical analyses of the data provided by the company and its impact on business performance for the long term. Through research, the level of relationship developed with customers and suppliers engaged in the production of industrial enterprises in Turkey and the level of integration among their functions have been identified and measured. This research is intended to make significant contributions to the understanding of industry in Turkey.

The purpose of this research is to measure the effect of internal integration levels of Istanbul Chamber of Industry’s top 500 enterprises (ICI 500) on the long-term relationship with customers and suppliers and the mediating role of the enterprise on the performance level. The hypothesis H1 was developed for this purpose.

H1: Internal integration has a mediating role in the interaction between long-term supplier-customer relationships and performance level of the enterprise.

The questions of the scale form, which is prepared to test the research hypothesis and to realize its aims, are designed by taking the expert opinions from the literature and previous studies. The question form that was previously published in the literature is based on the studies conducted in areas such as internal integration, operational performance, and the structure of long-term relations in the supply network, and has been presented to expert academics and business managers. The necessary corrections have been made to the questions within the framework of feedback. Information on the question structure of the scale developed are as follows:

Director and Business Features: The questions in this category address the department where the director works, the sector in which the business operates, the number of people working in the enterprise, and the number of years the business has been operating.

Long-Term Relationships Developed by Companies with Suppliers and Customers: The scale developed by Prajogo and Olhager (2012) was used for the long-term relationships of the enterprises with their suppliers. The scale developed by the authors has been rearranged according to the opinions of a group of six experts, two academics, and four directors. This scale was also adapted to measure the long-term relationship with customers.

Internal Integration Level of the Company: In order to measure the integration level of the internal functions of the enterprise, Huo (2012)’s integration scale was used. The scale questions were rotated within the framework of the opinions of the expert group consisting of two academics and four business directors. Internal integration and long-term relationship questions use a 5-point Likert scale. The Likert scale, unlike other scales used in scientific research, determines to what extent the respondent participates or not by asking them to rate an answer from 1 (strongly disagree) to 5 (strongly agree). In making this determination, the considerations are used without any change.

Business Performance: Performance measurement is crucial to improve supply chain management (Cazeri, et al., 2017). Within the framework of the expert group’s opinions on measuring the performance of the enterprise, the company's financial and fiscal data were not directly targeted. Therefore, the performance scale has been developed on the performance scales of Powell and Dent-Michallef (1997), which are widely used in the literature, according to the opinions of the expert group. All questions in the 5-point Likert scale (1 = Very low and 5 = Very high) were asked by the directors based on the main competitors of the company.

Pre-treatment is the process of questioning the validity and reliability of the questions with observational data. It is of utmost importance to determine the problems in the draft form of the scale, and it is very important that the study be conducted in a group with similar characteristics as the target group to obtain valid and reliable results (Büyüköztürk, 2005). In order to finalize the formed scale form, it was tested whether the questions were sufficient to collect the needed data. The aim of the pre-test process is to determine how comprehensible the questions are and to determine the conflicts and contradictions in the questions. The scale form was presented to five academics who are experts in the field of research at the preliminary stage of the research, and additions, subtractions, and corrections were made in some questions, considering their opinions.

In accordance with the opinions of the group of experts, the updated form was sent to the directors of four large-scale production enterprises, and they were asked to fill in the form and to write down the required notes on the form if there were incomplete or incomprehensible phrases. Based on the feedback received from the business directors, corrections were made to blend academic language and the language of the business world. Through the experts’ opinions, obtained during the pilot study, it was concluded that a high-level director can fill out the form, and the supply and marketing processes .

The research universe can be expressed as the community of research units with characteristics that match the goals of a study (Erkorkmaz and Günay, 2002). It is very difficult or even impossible to conduct a study when the universe is too large. Restrictions, such as budget, time, and personnel, prevent full counting in most studies. If the researcher accepts the possibility of a specific error, and if the time and financial means are inadequate to realize the full count, then the research can be applied on a sample that may represent the main body within certain confidence limits (Kurtuluş, 2010).

In this research, both the enterprise’s supplier and customer relationships were taken into consideration. Since a conceptual framework was designed to determine the impact of these relationships on internal integration, the most appropriate operating structure for this purpose was considered to be the industrial enterprises. For that reason, it was used the Istanbul Chamber of Industry (ICI 500), Turkey’s largest industrial enterprise. Turkey's top 500 industrial enterprises in the ICI 500 produced the most consistent and reliable data due to their operating volumes, market size, and history. Since 13 of the 2013 ICI 500 industrial enterprises did not disclose their names, a total of 487 industrial enterprises were accepted as the universe of the research.

The plan was to send the questionnaire to all of these enterprises; however, it was of great importance that the scale forms were not lost within the large organizational structure. For this reason, telephone contact was made with at least one manager from each enterprise. A person in any of the following positions could qualify as manager: general manager, assistant general manager, general coordinator, production manager, production assistant manager, marketing manager, and marketing assistant manager. A scale form was sent to each manager's personal mailing address and recipients were called two weeks after receipt, in addition to sending a reminder mail. A total of 119 scale forms were completed between March 2014 and March 2015. Two of the scale forms were eliminated for issues of response making a total of 117 scale forms obtained. The return rate of the scale forms was 24% (117/487 = 0.24).

The SPSS 16.0 statistical package program was used for statistical analysis of the data. First, frequency distributions for the responses obtained from the demographic questions were completed. Then, factor and reliability analyses were performed to determine the validity of the scales. Mean and standard deviation values of the research model variables were given. Correlation, simple regression, hierarchical regression analysis and mediation test analysis were then used to test the relationship between variables and the research hypothesis.

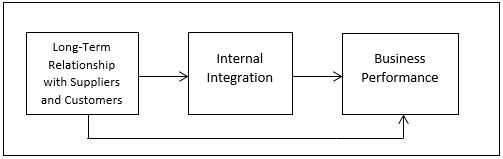

The companies included in the research were among the largest industrial companies in Turkey as established by the ICI. The supply network structure of enterprises is directly related to production. The participating companies were from a variety of sectors in Turkey, which aids in the generalization of the results. Table 1 shows the sectoral distribution of enterprises.

Table 1. Introductory information about enterprises

The examination of the department in which the respondents are working is extremely important in terms of their understanding of the research problem. When the departments where managers’ work are examined in Table 1, it is seen that they are in a position to give accurate data on the subjects that take into consideration the supply network structuring related to the purpose and problem of the research and its effect on the business performance, which increases the reliability of the data analyzed.

The number of employees of the enterprises gives information about whether the enterprises are engaged in labor-intensive or machine-intensive activities. The top 500 enterprises have the highest net sales production in Turkey. In addition, the enterprises have more automation-based production and higher use of outsourcing strategies. In both cases, high automation and outsourcing increase the need for both internal and external integration of enterprises. The employment numbers of the enterprises participating in the research are shown in Table 1. This research showed that labor-intensive production enterprises in Turkey with lower levels of automation used outsourcing as a business strategy less frequently. This may suggest that lower demand may be generated in terms of the needs of companies to integrate into the supply network.

In order to establish and maintain the supply network integration, enterprises must have long-term relationships with their customers and suppliers. This is due to the fact that integration requires high-cost investments and causes high sanctions for contract withdrawals. Therefore, the prolonged operation period of the enterprises is very important for the establishment of supply network integration. When Table 1 is analyzed, it is observed that approximately 95% of the enterprises participating in the research have sectoral activities of 10 years or more. This shows that companies have sufficient time to strengthen their relationships with other enterprises in their supply networks, and they have the sectoral knowledge and experience to achieve positive results if they enter into the integration effort.

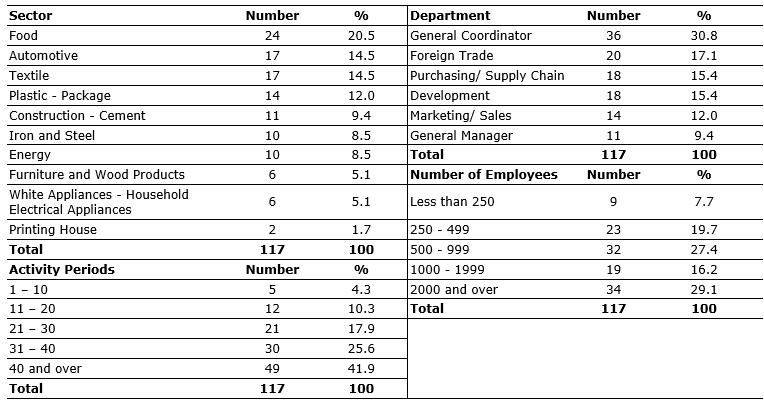

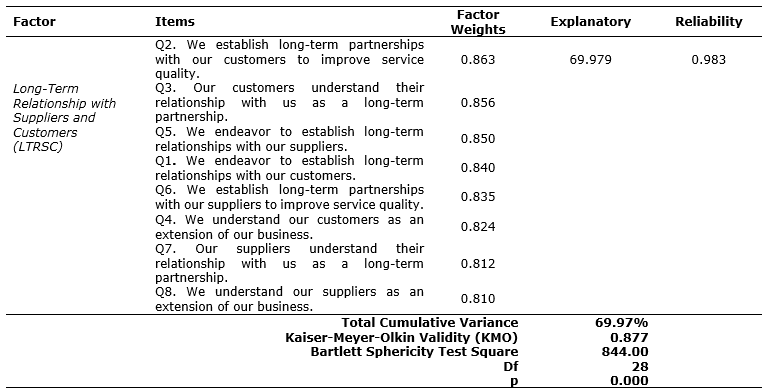

Exploratory factor analysis was performed in the first stage of the validity and reliability tests of the long-term relationship scale. In order to determine the construct validity of the long-term relationship scale, the principal component analysis and varimax rotation with the Kaiser Normalization method were used for factor analysis. The Kaiser-Meyer-Olkin (KMO) sample adequacy test and Bartlett's Test of Sphericity were used to assess the suitability of the data set for factor analysis. The KMO value was higher than 0.50, and the Bartlett Sphericity test value was significant at 0.05 and was found to be suitable for data set factor analysis (KMO= 0.877, Bartlett test 2= 844.020, p= 0.000).

As a result of the factor analysis, it was found that the factor weights of the scale were over 0.50, and a single factor with eigenvalues was obtained. The total percent variance explained was found as 69.979%. The reliability level of the factor was tested, and Cronbach’s alpha was used to calculate the internal consistency of the factor. As a result of the reliability analysis, Cronbach’s alpha value of long-term relationship with suppliers and customers (LTRSC) was determined as 0.983. The results are shown in Table 2.

Table 2. Factor analysis results and reliability values of long-term relationship scale with suppliers and customers

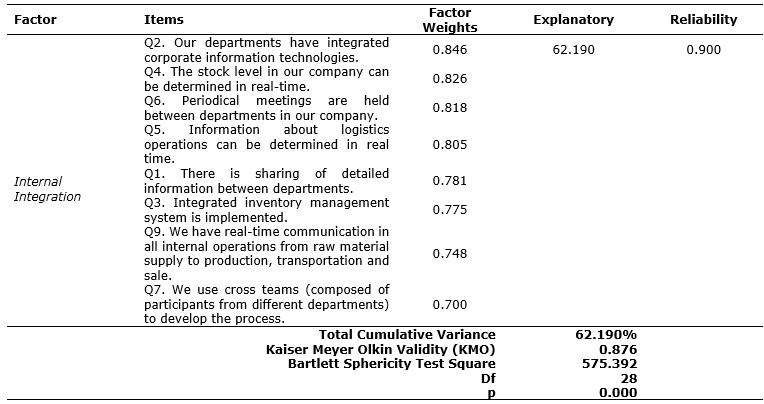

As a result of the reliability analysis for the internal integration factor, the Cronbach’s alpha value was found to be 0.900. The total percent variance explained was found as 62.190%. The results of internal integration factor analysis are shown in Table 3.

Table 3. Factor analysis results of internal ıntegration scale and reliability values

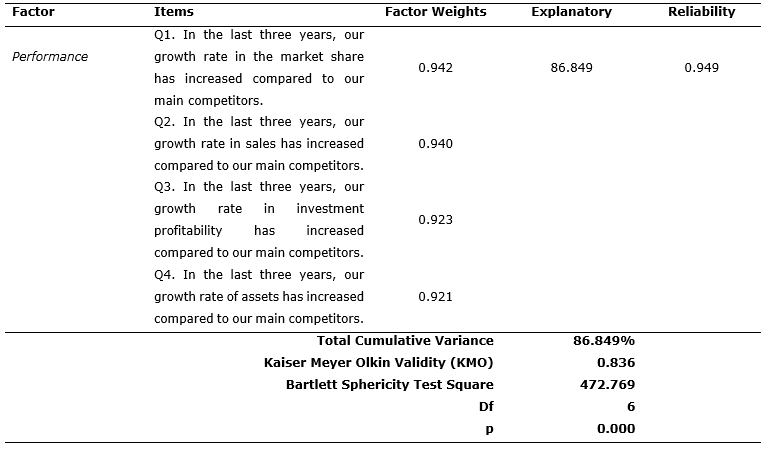

The exploratory factor analysis was performed to assess the validity and reliability tests of the performance scale. The total variance value explained by the performance factor was calculated as 86.849. As a result of the reliability analysis, Cronbach's alpha value for this factor was 0.949. The results of performance factor analysis are shown in Table 4.

Table 4. Factor analysis results and reliability values of performance scale

When the LTRSC is analyzed, the minimum value of the questions is calculated as 1 point, and the maximum value is 5 points. The mean value of the factor was calculated as 4.20 points. This result shows that it is important for enterprises to develop and maintain LTRSC. The mean value of internal integration was calculated as 3.77. The lowest value of this factor is 1.77, and the highest value is 5. This result shows that the internal integration levels of the enterprises are above the middle but not at the desired level. At the same time, this result indicates that enterprises should give more importance to the integration of internal processes in supply network operations.

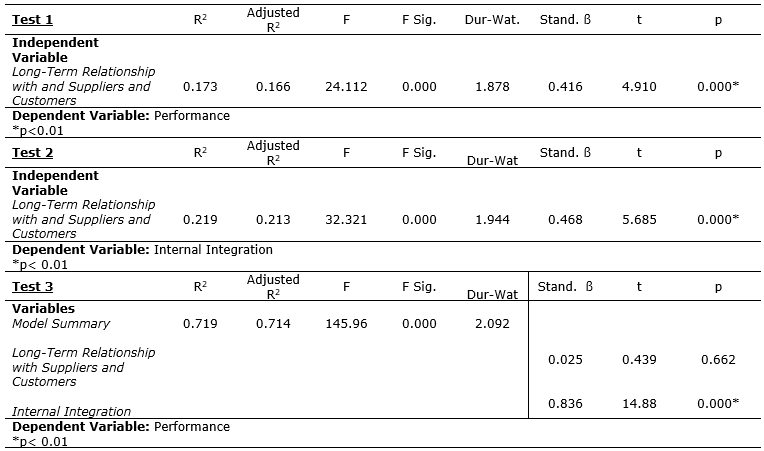

To test for mediation, a series of three regression analyses were performed as specified by Baron and Kenny (1986). First, the mediator (internal integration) was affected on the independent variables (long-term relationship with suppliers and customers). Second, the dependent variable (business performance) was affected on the independent variables. Third, the dependent variable was affected on both the independent variables and on the mediator. Separate coefficients for each equation were estimated and tested. Moreover, to establish mediation, the following conditions must be valid: The independent variables must affect the mediator in the first equation; they must be shown to affect the dependent variable in the second equation; and the mediator must affect the dependent variable in the third equation. If these conditions are met, then the effect of the independent variables on the dependent variable must be less in the third equation than in the second (Wu, 2008). Therefore, the hierarchical regression analysis performed to test the research model is shown in Table 5.

Table 5. Analysis results of the mediating role effect of internal integration in the relationship between long-term relationship and business performance with suppliers and customers

In the first phase of the analysis of the research model, the effect of the LTRSC variable on the business performance variable was examined. As a result of simple regression analysis, it is seen that LTRSC explained 16.6% of the change in performance (Adjusted R2 = 0.166, F Significance = 0.000). However, the standardized β coefficient, which shows the effect of LTRSC on performance, is 0.416 (p = 0.000). The results confirm that the LTRSC has a positive and direct impact on performance.

In the second phase of the model test, the effect of LTRSC on internal integration is examined. As a result of the simple regression analysis performed between the aforementioned variables, the adjusted R2 value was found to be 0.213 (F Significance = 0.000). This result shows that LTRSC explain 21.3% of the change in internal integration. At the same time, the effect of LTRSC on internal integration shows a positive and significant effect at 46.8% (p = 0.000). In order for internal integration to have a mediating effect, multiple regression analysis should have a significant effect on operational performance. Therewithal, LTRSC should not have a significant effect on the business performance. As a result of multiple regression analysis, it is seen that internal integration variables and LTRSC explain 71.4% of the change in performance variable (F significance = 0.000). The Durbin-Watson test found no autocorrelation among the variables (Durbin-Watson = 2.092). When the effects of LTRSC and internal integration on the business performance variable are examined separately, it is seen that the internal integration has a positive and significant effect (p = 0.000) on the business performance with 83.6%. However, the effect of LTRSC on the business performance is not significant at the level of p < 0.01 (p = 0.662). The findings show that the internal integration variable has a full mediating effect on the relationship between LTRSC and the business performance variable.

In today’s markets, the performance improvement efforts of the enterprises become ineffective out of collaborative networks. For this reason, enterprises establish collaborative structures with other businesses through supply networks. In this context, a lot of research has been done in the literature regarding the necessity of long-term enterprises with the suppliers (Wang et al., 2015; Krishnapriya and Baral, 2014; Prajogo and Olhoger, 2012; Cannon et al., 2010; Ryu et al., 2007; Spekman, 1998). The long-term relationship with suppliers has many benefits for businesses. First, long-term contracts with suppliers increase the quality of the goods and services received while providing cost advantages. In addition, as long-term relationships create strong trust, transaction costs also decrease. However, when collaborative changes occur, it has been shown that inter-enterprise confidence affects the organizational structure (Hoffmann et al., 2010). Past research has focused on the development of long-term relations with suppliers while the relationships between enterprises and customers have been neglected. However, businesses should be in close cooperation with their customers as well as their suppliers in a globally competitive environment. Through long-term relationships with customers, their expectations can be better understood, demand forecasts can be made more accurately, and efficiency increases in production planning. At the same time, the transaction costs will decrease as the confidence among the enterprises increase in this close relationship process. Therefore, enterprises should be able to address the long-term relationship development from both the supplier and the customer perspective. In this study, this case is especially emphasized.

In this case, a balance exists between long-term relationships, internal integration, and performance. The enterprise will want to establish long-term relationships with its suppliers and customers to improve its performance. This situation will cause pressure on the enterprise to realize internal integration. In this case, in order to increase operational performance, there is a need for mediation role of internal integration between long-term relationships with suppliers and customers and business performance. This is the conceptual framework and hypothesis of the research, based on the relevant literature. Accordingly, the aim of the research is to fill an important gap in the related literature.

The findings showed that internal integration has a full mediating effect between long-term relationship and performance. The hypothesis of such research (H1) has been confirmed. In this context, the importance of internal integration for industrial enterprises has been put forward. Enterprises that want to develop long-term relationships with suppliers and customers must ensure the integration between their internal functions. Otherwise, an increase in operating performance would be extremely difficult. In this context, it is recommended that Turkish industrial enterprises should perform their internal integration first for an effective supply network management. Similarly, industrial enterprises of other developing countries should complete their internal integration to improve performance. There are many studies available examining the effect of internal integration on business performance (Mbugua and Namada, 2019; Syed et al., 2019; Pakurár et al. 2019; Thai and Jie, 2018) However, discussions on the impact of long-term relationships with customers and suppliers regarding internal integration are insufficient. In this sense, the research model has a theoretical contribution.

If an assessment of the limits of the research is required, the relationship between variables in industrial enterprises must be first examined. Additionally, the research was conducted only among the largest industrial companies of a developing country. These findings are relevant to the emerging economies of the world, where local trade relations of developing economies may show similar characteristics. In particular, the globalization process causes these enterprises to perform similar operations. Such similar operations have similar problems and the local impact on these problems is not strong. Therefore, enterprises in developing countries may benefit from the results of this research. In this context, comparative studies between developing countries can produce interesting results. In addition, many parts of global manufacturing enterprises are spread around the world. Therefore, many countries contribute to the information to be obtained from these companies. Therefore, the results are of interest to these countries. In this respect, the research aims to contribute to international supply networks and operation literature. While circumstances may be different in more economically advanced nations, information about these relationships in one country is also meaningful for other countries.

Accordingly, similar future studies in different developing countries will contribute to increased global knowledge on the internal structure of supply networks. Developing countries can adapt their unique conditions to the model as a control variable. At the same time, research on the mediating role of other variables affecting the link between long-term relationships with customers, suppliers and business performance will deepen the knowledge on the subject.

Alexandru, C. (2014), “An exploratory approach to integration of business practices in supply chain management”, Annals of the University of Oradea, Economic Science Series, Vol. 23, No. 1, pp. 1125-1134.

Aula, H.R.M.; Erna, M.; Margo, P. (2018), “Supply chain integration in small medium enterprises: a systematic literature review”, RJOAS, Vol. 1, No. 73, pp. 131-140. DOI: 10.18551/rjoas.2018-01.17

Baron, R.M.; Kenny, D.A. (1986), “The moderator-mediator variable distinction in social psychological research: conceptual, strategic, and statistical considerations”, Journal of Personality and Social Psychology, Vol. 51, No. 6, pp. 1173-1182. DOI: 10.1037//0022-3514.51.6.1173

Büyüköztürk, Ş. (2005), “Scale Development”, The Journal of Turkish Educations Sciences, 3(2): 133-148.

Campbell, J.; Sankaran, J. (2005), “An inductive framework for enhancing supply chain integration”, International Journal of Production Research, Vol. 43, No. 16, pp. 3321-3351. DOI: 10.1080/00207540500095852

Cannon, J.P.; Doney, P.M.; Mullen, R.M.; Petersenc, K.J. (2010), “Building long-term orientation in buyer–supplier relationships: the moderating role of culture”, Journal of Operations Management, Vol. 28, pp. 506-521. DOI: 10.1016/j.jom.2010.02.002

Capaldo, A.; Giannoccaro, I. (2015), “How does trust affect performance in the supply chain? The moderating role of interdependence”, International Journal of Production Economics, Vol. 166, pp. 36-49. DOI: 10.1016/j.ijpe.2015.04.008

Cazeri, G.T.; Anholon, R.; Ordoñez, R.E.C.; Novaski, O. (2017), “Performance measurement of green supply chain management: a literature review and gaps for further research”, Brazilian Journal of Operations & Production Management, Vol. 14, pp. 60-72. DOI: 10.14488/BJOPM.2017.v14.n1.a7

Chang, H.H. (2009), “An empirical study of evaluating supply chain management integration using the balanced scorecard in Taiwan”, The Service Industries Journal, Vol. 29, No. 2, pp. 185-202. DOI: 10.1080/02642060802294961

Cousins, P.D.; Menguc, B. (2006), “The implications of socialization and integration in supply chain management”, Journal of Operations Management, Vol. 24, pp. 604-620. DOI: 10.1016/j.jom.2005.09.001

Demeter, K.; Szász, L.; Rácz, B.G. (2016), “The impact of subsidiaries’ internal and external integration on operational performance”, International Journal of Production Economics, Vol. 182, pp. 73-85. DOI: 10.1016/j.ijpe.2016.08.014

Droge, C.; Jayaram, J.; Vickery, S.K. (2004), “The effects of internal versus external integration practices on time-based performance and overall firm performance”, Journal of Operations Management, Vol. 22, No. 6, pp. 557-573. DOI: 10.1016/j.jom.2004.08.001

Droge, C.; Vickery, S.K.; Jacobs, M.A. (2012), “Does supply chain integration mediate the relationships between product/process strategy and service performance? An empirical study”, International Journal of Production Economics, Vol. 137, pp. 250-262. DOI: 10.1016/j.ijpe.2012.02.005

Errassafi, M.; Abbar, H.; Benabbou, Z. (2019), “The mediating effect of internal integration on the relationship between supply chain integration and operational performance: Evidence from Moroccan manufacturing companies”, Journal of Industrial Engineering and Management, Vol. 12, No. 2, pp.254-273. DOI: 10.3926/jiem.2794

Erkorkmaz, Ü.; Günay, O. (2002), “Sampling Methods and an Application”. Journal of Health Sciences, Vol. 11, No.1, pp. 36-34.

Gattorna, J.L.; Walters, D.W. (1996), Managing the supply chain: A strategic perspective, 1st ed. London: Palgrave Macmillan Press Ltd.

Flynn, B.B.; Huo, B.; Zhao, X. (2010), “The impact of supply chain integration on performance: a contingency and configuration approach”, Journal of Operations Management, Vol. 28: pp. 58-71. DOI: 10.1016/j.jom.2009.06.001

Hamali, S.; Prihandoko, D.; Kurniawan, S.; Ramdhani, R. (2020), “The effects of supply chain information integration on organizational performance in food small industry”, Management Science Letters, Vol. 10, No. 3, pp. 695-702. DOI: 10.5267/j.msl.2019.9.009

Han, J.; Lu, H.H.; Trienekens, J.H.; Omta, S.W.F. (2013), “The impact of supply chain integration on firm performance in the pork processing industry in China”, Chinese Management Studies, Vol. 7, No.2, pp.230-252. DOI: 10.1108/CMS-Jun-2011-0034

Handfield, R.B.; Nichols JR., E.L. (1999), Introduction to supply chain management, New Jersey: Prentice-Hall Inc.

Hoffmann, W. R.; Neumann, K.; Speck G. (2010), “The effect of interorganizational trust on make-or-cooperate decisions: Disentangling opportunism-dependent and opportunism-independent effects of trust”, European Management Review, Vol. 7, No. 2, pp.101-115. DOI: 10.1057/emr.2010.8

Kim, S. W. (2006), “Effects of supply chain management practices, integration and competition capability on performance”, Supply Chain Management: An International Journal, Vol. 11, No. 3, pp. 241-248. DOI: 10.1108/13598540610662149

Krishnapriya V.; Baral, R. (2014), “Supply chain integration – a competency based perspective”, International Journal of Managing Value and Supply Chains, Vol. 5, No. 3, pp. 45-60. DOI: 10.5121/ijmvsc.2014.5304

Koçoğlu, İ.; İmamoğlu, S.Z.; İnce, H.; Keskin, H. (2011), “The effect of supply chain integration on information sharing: enhancing the supply chain performance”. 7th International Strategic Management Conference / Procedia Social and Behavioral Sciences, Vol. 24, pp. 1630-1649. DOI: 10.1016/j.sbspro.2011.09.016

Koufteros, X.; Peng, X. (D).; Lu, G.; Peters, R. (2014), “The impact of organizational structure on internal and external integration”, Journal of Organization Design, Vol. 3, No. 2, pp. 1-17. DOI: 10.7146/jod.7386

Kurtuluş, K. (2010), Research Methods, İstanbul: Türkmen Publishing.

Lofti, Z.; Mukhtar, M.; Sahran, S.; Zadeh, A.T. (2013), “Information sharing in supply chain management”, Procedia Technology, Vol. 11, pp. 298-304. DOI: 10.1016/j.protcy.2013.12.194

Mackelprang, A. W.; Robinson, J.L.; Bernardes, E.; Webb, G.S. (2014), “The relationship between strategic supply chain integration and performance: A meta-analytic evaluation and implications for supply chain management research”, Journal of Business Logistics, Vol. 35, No. 1, pp. 71-96. DOI: 10.1111/jbl.12023

Mbugua, A.W.; Namada, J. (2019), “Information technology integration effect on operational performance of Kenya’s public health sector”, Integrated Journal of Business and Economics, Vol. 3, No. 3, pp. 226-239. DOI: 10.20525/ijrbs.v8i5.472

Mentzer, J. T.; DeWitt, W.; Keebler, J. S.; Min, S.; Nix, N. W.; Smith, C. D.; Zacharia, Z. G. (2001). “Defining supply chain management”, Journal of Business Logistics, Vol. 22(2), pp. 1-25. DOI: 10.1002/j.2158-1592.2001.tb00001.x

Official Gazette, 2005, Regulation on the Definition, Qualifications and Classification of Small and Medium-Sized Enterprises, 18/11/2005, No: 25997.

Özdemir, D.; Doğan, Ö. (2012), “Supply chain integration and information technologies”, Erciyes University Journal of the Social Sciences Institute, Vol. 28, No. 1, pp. 19-41.

Pakurár, M.; Haddad, H.; Popp, J., Khan, T.; Oláh, J. (2019), “Supply chain integration, organizational performance and balanced scorecard: An empirical study of the banking sector in Jordan”, Journal of International Studies, Vol. 12, No. 2, pp. 129-146. DOI: 10.14254/2071-8330.2019/12-2/8

Powell, T.C.; Dent-Micallef, A. (1997), “Information technology as competitive advantage: the role of human, business, and techology resources”, Strategic Management Journal, Vol. 18, No. 5, pp. 375-405. DOI: 10.1002/(SICI)1097-0266(199705)18:5<375:AID-SMJ876>3.0.CO;2-7

Prajogo, D., Olhager, J. (2012), “Supply chain integration and performance: the effects of long-term relationships, ınformation technology and sharing, and logistics integration”. International Journal of Production Economics, Vol. 135, No. 1, pp. 514-522. DOI: 10.1016/j.ijpe.2011.09.001

Richey, R. G.; Roath, A.S.; Whipple, J.P. (2010), “Exploring a governance theory of supply chain management: barriers and facilitators to integration”, Journal of Business Logistics, Vol. 31, No.1, pp. 237-256. DOI: 10.1002/j.2158-1592.2010.tb00137.x

Ryu, S., Park, J.E.; Min, S. (2007), “Factors of determining long-term orientation in interfirm relationships”, Journal of Business Research, Vol. 60, pp. 1225-1233. DOI: 10.1016/j.jbusres.2006.09.031

Shou, Y.; Li, Y.; Park, Y.; Kang, M. (2018), “Supply chain integration and operational performance: the contingency effects of production systems”, Journal of Purchasing and Supply Management, Vol. 24(4), pp. 352-360. DOI: 10.1016/j.pursup.2017.11.004

Silva, F.A.; Oliveira, V.M. (2017), “Impact analysis of it use in logistical costs of a Brazilian beverage company”, Brazilian Journal of Operations & Production Management, Vol. 14, pp. 20-26. DOI: 10.14488/BJOPM.2017.v14.n1.a3

Spekman, R. E.; Kamauff JR, J.F.; Myhr, N. (1998), “An empirical investigation into supply chain management a perspective on partnerships”, International Journal of Physical Distribution & Logistics Management, Vol. 28, No. 8, pp. 630-650. DOI: 10.1108/13598549810215379

Swafford, P. M.; Ghosh, S.; Murthy, N. (2008), “Achieving supply chain agility through it integration and flexibility”, International Journal of Production Economics, Vol. 116, No. 2, pp. 288-297. DOI: 10.1016/j.ijpe.2008.09.002

Swink, M.; Narasimhan, R.; Wang, C. (2007), “Managing beyond the factory walls: Effects of four types of strategic integration on manufacturing plant performance”, Journal of Operations Management, Vol. 25, pp. 148-164. DOI: 10.1016/j.jom.2006.02.006

Syed, M.W.; Li, J.Z.; Junaid, M.; Ye, X.; Ziaullah, M. (2019), “An empirical examination of sustainable supply chain risk and integration practices: a performance-based evidence from Pakistan”, Sustainability, Vol. 11, No. 19, pp. 1-21. DOI: 10.3390/su11195334

Thai, V.; Jie, F. (2018), “The impact of total quality management and supply chain integration on firm performance of container shipping companies in Singapore”, Asia Pacific Journal of Marketing and Logistics, Vol. 30, No. 3, pp. 605-626. DOI: 10.1108/APJML-09-2017-0202

Vachon, S.; Klassen, R.D. (2007), “Supply chain management and environmental technologies: the role of integration”, International Journal of Production Research, Vol. 45, No. 2, pp. 401-423. DOI: 10.1080/00207540600597781

Vankireddy, K., Baral, R. (2019), “Organisational and inter-organisational competencies for supply chain integration”, International Journal of Process Management and Benchmarking, Vol. 9, No. 1, pp. 101-123. DOI: 10.1504/IJPMB.2019.10019076

Yörükoğlu, M.; Kayakutlu, G.; Ercan, S. (2014), “Knowledge system utilisation in supply chain management: a model for knowledge sharing in avıation land services”, Journal of Aeronautıcs and Space Technologies, Vol. 7, No.1, pp. 1-23.

Yüksel, H. (2002), “Importance of knowledge in supply chain management”, Dokuz Eylül University The Journal of Graduate School of Social Sciences, Vol. 4, No. 3, pp.261-279.

Wang, C.L.; Shi, Y.; Barnes, B.R. (2015), “The role of satisfaction, trust and contractual obligation on long-term orientation”, Journal of Business Research, Vol. 68, pp. 473-479. DOI: 10.1016/j.jbusres.2014.09.016

Wolf, J. (2011), “Sustainable supply chain management integration: a qualitative analysis of the German manufacturing ındustry”, Journal of Business Ethics, Vol. 102, pp. 221-235. DOI: 10.1007/s10551-011-0806-0

Wu, W.P. (2008), “Wu, W. P. (2008). Dimensions of social capital and firm competitiveness improvement: The mediating role of information sharing”, Journal of management Studies, Vol. 45, No. 1, pp. 122-146. DOI: 10.1111/j.1467-6486.2007.00741.x

Zailani, S.; Iranmanesh, M.; Foroughi, B.; Kim, K.; Hyun, S.S. (2019) “Effects of supply chain practices, integration and closed-loop supply chain activities on cost-containment of biodiesel”, Review of Managerial Science, pp. 1-21. DOI: 10.1007/s11846-019-00332-9

Received: 25 Jun 2019

Approved: 28 Oct 2019

DOI: 10.14488/BJOPM.2019.v16.n4.a5

How to cite: Toker, K; Pinar, R. I. (2019), “The Mediating Role Effect of Internal Integration Between Long Term Relationship with Suppliers and Customers and Business Performance in Turkey ICI 500 Enterprises”, Brazilian Journal of Operations & Production Management, Vol. 16, No. 4, pp. 592-604, available from: https://bjopm.emnuvens.com.br/bjopm/article/view/837 (access year month day).