Procedure for identifying factors and interfaces that are critical in a sustainable product

Istefani Carísio de Paula

istefanicpaula@gmail.com

Federal University of Rio Grande do Sul – UFRGS, Porto Alegre, Rio Grande do Sul, Brazil

Daniel Augusto Hoppe

danielhoppe@unisc.br

University of Santa Cruz do Sul – UNISC, Santa Cruz do Sul, Rio Grande do Sul, Brazil

Ângela Maria Marx

angela.marx@ufrgs.br

Federal University of Rio Grande do Sul – UFRGS, Porto Alegre, Rio Grande do Sul, Brazil

Julio Carlos de Souza van der Linden

julio.linden@ufrgs.br

Federal University of Rio Grande do Sul – UFRGS, Porto Alegre, Rio Grande do Sul, Brazil

ABSTRACT

Goal: To test a systematic procedure for identifying critical factors and interfaces among the stakeholders involved with the lifecycle of a sustainable product, with a view to make design prioritizations.

Design/Methodology/Approach: A qualitative-quantitative approach including interviews and requirements analysis led to the definition of relationships in network graphical representations. Stakeholders from hygiene and cleaning products (HCP) manufacturing and consumption segment were interviewed in the state of Rio Grande do Sul, Brazil.

Results: Factors and interfaces that are critical for a sustainable system were highlighted by the procedure and they include: human resources training, research funding, waste collection systems, and people's behavior towards product discarding.

Limitations of investigation: This is an exploratory study performed in a single segment: the hygiene and cleaning products (HCP).

Practical implications: The understanding of the behavior of professionals in the hygienic product-manufacturing segment.

Originality/value: To explore a new way for identification of critical elements in a sustainable network system.

Keywords: Systematic Procedure; Critical Factor; Critical Stakeholders; Lifecycle; Sustainable Product.

1. INTRODUCTION

Studies have shown that product sustainability may be ultimately compromised when stakeholders fail to commit to sustainability goals from the time raw materials are extracted up to the point a product is finally disposed of or revalued. For instance, regarding end-consumers, Marx et al. (2010) and Park et Ha (2012) say that it is necessary to learn how they behave so factors that encourage them to act sustainably or discourage them from doing so can be identified. Almeida et al. (2009) highlight that, the consumers' awareness notwithstanding, more often than not they are merely interested in product prices and operating quality.

According to Akatu Institute [1] (2009) most consumers fail to act sustainably because they associate their responsibility solely to the purchase phase of consumption. People ordinarily equate consuming to buying, which is correct albeit incomplete, because buying is simply a phase of the multiple-phase process known as consumption. Before that, consumers need to decide what to consume, why, how, and from whom. A purchase should take place only after people have thought about those aspects. Then, after the purchase, there are the phases of using and discarding what had been bought.

Marx et al. (2010) conducted a study among a group of eco-oriented consumers in the city of Porto Alegre, Rio Grande do Sul, and enumerated factors that encouraged and discouraged them to/from acting sustainably in the purchase, use, and disposal of hygiene and cleaning products (HCP). Some factors included: lack of information on proper product disposal, lack of knowledge about ecology, sustainable product quality (price, outward aspect, availability, variety, efficiency), stores (product display, advertising, store location, store availability), issues related to trash collection systems, and others.

The factors identified by Marx et al. (2010) were converted into requirements, and the stakeholders involved were identified regarding each requirement. Hence, the procedure to identify factors and convert them into requirements revealed that the actions by other stakeholders involved in a product's lifecycle, such as manufacturers, retailers, city agencies in charge of urban cleaning, agencies responsible for campaigns to educate the population, and others, interface with the end-consumers' actions and were seen as critical for sustainability by these consumers. Authors believe that a product will hardly be sustainable in case the various stakeholders in the product system's lifecycle fail to achieve sustainability goals (Kazazian, 2005; Thackara, 2008; Noro et al., 2010). From the product design standpoint, a design's scope must reach beyond marketing efforts that assess needs for the product's use phase and be expanded to its entire lifecycle. That means designing not a mere product, but a product within its system (McDonough et Braungart, 2002; Kazazian, 2005; Kota et Chakrabarti, 2007; Schendel et Birkhofer, 2007; Vezzolli et Manzini, 2008; Hansen et Andreansen, 2010).

By analyzing the factors that encourage and discourage end-consumers in the study by Marx et al. (2010), the elements of the system in which the product analyzed is inserted are found. Some of this system's links or stakeholders show up clearly as manufacturers and retailers. However, as the factors pointed out are interpreted, it is noticed that the system's project should consider the needs of other stakeholders that are not directly related to the product's lifecycle, such as public urban cleaning agencies, agencies in charge of creating environmental awareness and education, and others. It would be fair to say that the integrated actions by these stakeholders, as seen by end-consumers, may be critical for the system's success; thus, a few questions emerge from the study by Marx et al. (2010). Considering the standpoint of the other stakeholders in the product's lifecycle, are these interfaces the same? How do we identify the critical interfaces for a given product system? Considering this complexity of a sustainable system what factors may affect its success?

The design method by Donaldson et al. (2006), called Customer Value Chain Analysis (CVCA), provides a tool to analyze critical interfaces during the product definition phase, based on the competitive advantages afforded by the business model, according to the product that is being designed. Papers about Product Service System (PSS) have shown that the authors defined the parties involved with the product system being developed but failed to report why these parties were deemed relevant (Kazazian, 2005; Van Halen et al., 2005; Vezzolli et Manzini, 2008).

Therefore, the overall purpose of this paper is to test a systematic procedure for identifying critical interfaces and factors among the stakeholders involved with the lifecycle of a sustainable product, with a view to make design prioritizations. The procedure was designed based on the hypothesis that assessing and analyzing the factors that encourage and discourage the parties involved with a product system's lifecycle may become a procedure to identify interfaces for this system's design. The specific purposes include: assessing the factors that encourage or discourage a given system's stakeholders in terms of pursuing sustainability goals, and analyzing the resulting interfaces.

The research method used for this paper to attain its goal was an exploratory case study, and the technical procedure was approached from a qualitative/quantitative point of view. This study is limited by the fact that the design activity-supporting procedure was applied to a single product system, more specifically between six parties involved with the manufacturing and consumption of hygiene and cleaning products (HCP) in south Brazil. The product line chosen for the case study is being studied by the Industrial Engineering Post Graduate Program at the Federal University of Rio Grande do Sul (PPGEP/UFRGS) due to the negative impact of such products on the environment (Azevedo et Chasin, 2004; Strujak et Vidal, 2007; Teixeira et Cartonilho, 2007; Santos et al., 2009).

HCP manufacturing and consumption systems are known for being extremely harmful for the environment, and especially for being essential to meet the entire population's basic everyday needs. According to Dormer (1995) and Forty (2007), society has reached high standards of hygiene and cleanliness, and that gives companies constant opportunities for developing and offering such products. Santos et al. (2009) point out that more people now consume these products, and in greater amounts. Additionally, because these products meet the basic needs of all human beings, their consumption system comprises customers from all walks of life and who have a wide variety of characteristics, habits, and lifestyles. For such reason, store managers have been paying special attention to the section where these products are displayed, given that a high number of them are bought on impulse. Manufacturers put in efforts and high investments to increase their product mix, design packaging, and do merchandising. However, designers need to come up with more creative solutions to tackle the paradox between people's inordinate pursuit of hygiene and cleanliness and respect for the environment (Santos et al., 2009). The theoretical contribution is to explore a new way for identifying critical elements in a system. The practical contribution is the understanding of behavior of professionals in the hygienic production segment.

2. METHOD

This paper discusses an exploratory case study. Exploratory studies increase our level of familiarity with relatively unknown phenomena and provide information that helps define priorities for subsequent studies (Gil, 1991; Silva et Menezes, 2001). Case studies investigate a current phenomenon within its actual context through several sources of evidence. To conduct this study as a whole, three main sources of evidence were used: (i) information found in the sustainable product design literature, (ii) results from the pilot study carried out by Marx et al. (2010), and (iii) individual interviews with the parties involved in a HCP manufacturing and consumption system. The results from interviews used as the third source of evidence in this study will make it possible to confirm whether the procedure previously developed and tested in this paper achieves the goals initially set for the research.

The procedure to identify critical interfaces between different stakeholders in a sustainable product system was created based on a literature review and on previous studies conducted by our research group (Gomes et Damázio, 1992; Mizuno et Akao, 1994; Ribeiro et al., 2000; Ribeiro et Milan, 2004; Donaldson et al., 2006; Mourão, 2006; Passos et al., 2008; Marx, 2009; Marx et al., 2010). It is composed by four main stages divided in 14 steps, as shown in Figure 1.

Figure 1. Procedure for identifying critical interfaces between the parties involved in a sustainable product system's lifecycle

(1) Guidelines definition

The first stage consists in setting some guidelines for the study. It starts with the definition of the product system that will be investigated to understand its lifecycle and define who the stakeholders are. It is very important, considering the study's core goal is to identify critical interfaces based on stakeholders’ sustainability requirements. In case there are a high number of stakeholders making it unfeasible to globally assess the information, it may be necessary to define stratification variables and create groups. From those distributed in the groups, it will be possible to select interviewees whose opinions may represent the population of interest.

(2) Data collection

The second stage covers the creation and application of the instrument to collect the stakeholder’s opinion on the factors that encourage/discourage the consumption of sustainable products. In this study, a semi-structured interview plan, containing open-ended questions, was used to assess that information. The objective of the interview is to identify the factors that favor or disfavor the fact that hygiene products are sustainable in their system. The scheme of a lifecycle of a product was presented to the interviewees and they were asked to inform: (i) the lifecycle phases their processes comprised; (ii) factors that favor/disfavor the sustainable HCP system concerning government policies; economic factors; social factors; technological factors; environmental factors; legal factors; consumer factors; (iii) internal factors, such as people; strategies; structure, and processes; (iv) factors concerning the product lifecycle as resources extraction; manufacturing; packaging; distribution; retailing; consumer acquisition; and final disposition. The interview plan was tested, adjusted and approved by the project team before it was applied. After that, the interviews were recorded (audio) and the answers were transcribed. Alternatively, it is possible to use a questionnaire to collect this kind of information as in Marx et al. (2010).

(3) Data treatment

The third stage deals with the identification of factors that favor/disfavor the sustainable HCP in its system and the translation of this information into requirements following the Requirements Management theory (Kotonya et Sommerville, 2000; Young, 2003; Marx, 2009). After the identification of excerpts containing factors, it is necessary to codify them, rephrase them, if necessary, and identify the stakeholders involved with such factors.

Then, the factor-containing sentences are rewritten as requirements, employing standardized language to avoid misunderstandings. According to Young (2003) and Marx et al. (2010), the use of ‘must’ facilitates the requirement comprehension because it is a characteristic that should be provided, e.g. ‘Products must be available in large volumes’. The requirements are grouped up to eliminate redundancies (each requirement expresses a need different from other requirements) and allocated in categories/groups. The interdependence between requirements is also analyzed to reduce the number of requirements that should be rated by the interviewees. In the end, interviewees must evaluate the importance of their requirements to identify the most relevant requirements to each stakeholder using a suitable scale.

(4) Interfaces analysis

The last stage is the identification of stakeholders’ interfaces through the creation of individual requirements maps and an overall map that shows graphically critical relations for the case.

First, we create one individual map for each interviewee. The most important requirements for each stakeholder and the other parties related to them are recorded on a map and are interconnected through lines and origin codes to show their interfaces. An arrow line coming from a stakeholder towards a requirement indicates his responsibility for the action. If this requirement influences other parties, there will be also arrow lines departing from the requirement to the parties. Lines moving from different stakeholders towards a requirement suggest cooperation that is needed to fulfill that requirement. The syntax to graphically represent the interfaces between stakeholders will be explained in the sequence (see syntax to represent the interfaces).

After, it is created an overall map containing only the requirements scoring higher weighted values from each interviewee's map to show all the stakeholders and the critical interfaces. Stakeholders involved with the highest number of requirements (with many lines) can be considered more critical while stakeholders lacking requirements (with few lines) are not deemed critical.

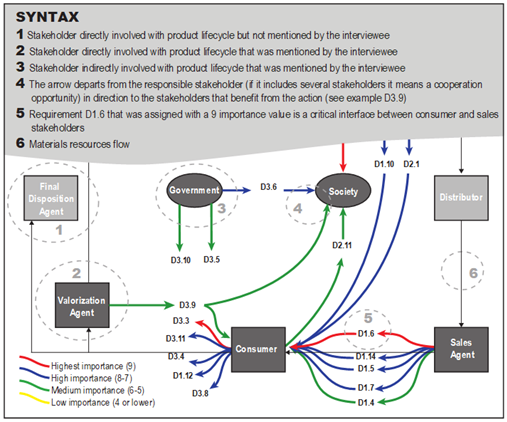

2.1 Syntax to represent the interfaces

To draw up the maps, it was created a syntax (illustrated in Figure 2) based on data from the study conducted by Marx et al. (2010). The parties related to each requirement must be recorded on a map and interconnected through unbroken lines and interview excerpt's origin codes to show the interfaces. The parties directly involved with the product system's lifecycle are represented by squares. A light-colored square means that party was not mentioned by the interviewee (e.g. distributor and final disposition agent in Figure 2). Parties indirectly involved with the lifecycle are represented by oval shapes on the map (e.g. society and government agencies - Figure 2). The arrow lines go from the party/parties deemed responsible for the action towards the requirement and from the requirement towards other party/parties related to its benefit. Lines moving from different stakeholders towards a requirement suggest cooperation is needed to fulfill the requirement. Unbroken line colors represent each requirement's importance, according to the syntax key. Requirements whose importance is rated 9 represent critical interfaces between stakeholders. Dotted lines represent the flows of material resources. Figure 2 shows the syntax intended to graphically represent the interfaces between the stakeholders.

Figure 2. Syntax representing the map of interfaces among the parties involved with a HCP system's lifecycle

3. RESULTS AND DISCUSSION

This section contains the results attained with the application of the method in a case study followed by a discussion.

3.1 Guidelines definition

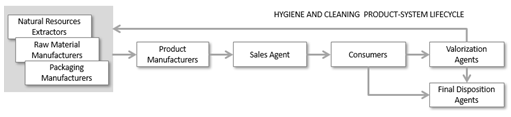

This stage covers the following tasks: choose the product system, define the product system stakeholders and select the interviewees. The authors conducted the case study in an HCP system in south Brazil. Such choice is justified by how important these products are to meet the basic everyday needs of the population; the importance of this sector for national and local economies; the close relationship of the product system with environmental degradation; and the chance to build the work done by Marx et al. (2010). For the identification of the product system stakeholders, it was considered literature information and data from previous studies concerning the product lifecycle, as shown in Figure 3.

Figure 3. HCP system's lifecycle, with distribution/transportation represented by arrows.

Source: Adapted from Hauschild et al. (2005) and Marx et al. (2010)

Considering the variety of products under the label “hygiene and cleaning”, the lifecycle is generally represented in Figure 3. Suppliers appear in the gray box on the left and comprise many different chemical and product industries. The product manufacturers can produce beauty products and baby diapers (hygiene) or even laundry detergent (cleaning). As sales agents we have drugstores, markets, supermarkets, department stores, among others. The consumers’ group comprises ordinary people but also hotels, hospitals and other service businesses. In the end of the lifecycle there are valorization agents as sorting centers and recycling companies that close the cycle for part of the materials (plastic, paper and metal from packages). However, a great amount of these products ends in sanitary landfills or as wastewater.

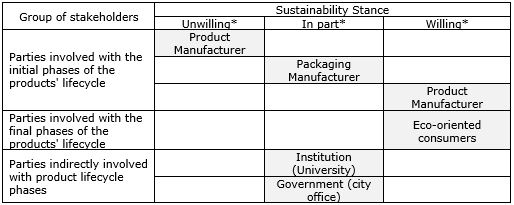

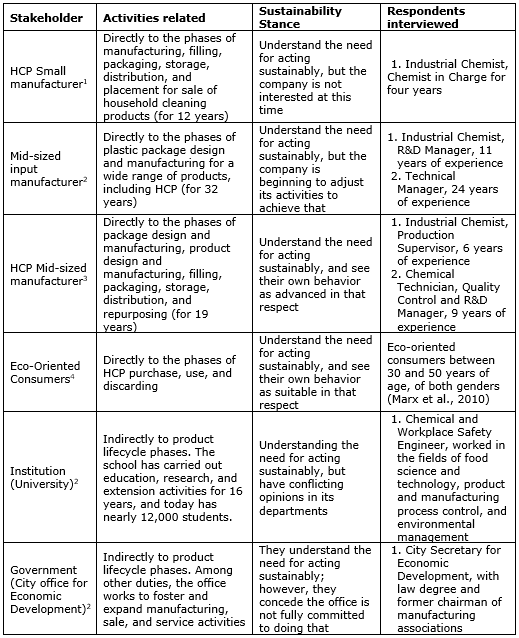

The selection of the stakeholders for interviews include: i) the parties involved with the lifecycle phases may have different points of view as a result of the phase they operate in within the cycle; and ii) companies have different positions in terms of sustainability. Chart 1 shows the stakeholders selected for the interviews, considering the group they belong to in the HCP lifecycle and the sustainability willingness.

Chart 1. The six stakeholders selected for the interviews

- Unwilling: Group that does not have a position of interest in sustainability; In part: group that is in transition to a sustainable stance or that only some departments/parties have that interest; Willing: group that has a position of interest in sustainability.

The following product system lifecycle phases were addressed through the six interviewees selected, including their primary and secondary activities: input (packaging) manufacturing; product manufacturing; distribution; placement for sale; purchase; use; discarding; and repurposing. For that reason, the scope of this study is limited to the extent that the representatives of the parties involved with activities directly related to the phases of resource extraction, input synthesis, and final disposal were not interviewed.

After the interviewees were defined, the interviews were scheduled for dates, places and times chosen by the respondents, except for consumers, given that the consumer-related data obtained by Marx et al. (2010) was considered in the analysis carried out in this study. The authors interviewed called the eco-oriented consumers formally educated towards sustainability. The open-ended questionnaire followed by the authors was used to prepare the data collection tool applied to the other five interviewees.

3.2 Data collection

In keeping with the procedure's goal, the interviews focused on eliciting from each interviewee the factors that encourage and discourage the respective stakeholders with respect to working to ensure the product system is sustainable. A questionnaire was prepared with open-ended questions for the semi-structured interviews and subjected to a pilot test. The questionnaire was applied to a small manufacturer of HCP, adjusted, and its modified version was approved (see method section 3).

Afterwards, the representatives from the interviewee categories were scheduled, as described in Chart 2. Note that the chosen respondents hold management positions and experience in the companies/institutions areas, so they could provide useful information about the population of interest.

Chart 2. Characteristics of the stakeholders interviewed

Stakeholders’ location: [1] city of 65,000 in the state's countryside; [2] city of 120,000 in the state's countryside; [3] city of 20,000 in the state's countryside; [4] State Capital.

Interviews were conducted and the data recorded in audio. Before carrying out the data collection procedure, a clarification was made. Considering each interviewee might have had a different idea regarding sustainability, in order to mitigate the effects of such varying opinions, the respondents were asked about what they thought a sustainable product was. Then, the concept adopted in this study, as taken from the Brundtland Commission (1987), was clarified. The information was immediately written down after the end of each data collection procedure.

3.3 Data treatment

The data treatment stage comprehends the clarification of the elicited data from each stakeholder and its conversion into requirements. The steps described in the sequence were conducted for each interviewee answers in order to obtain the lists with the most important requirements for each stakeholder.

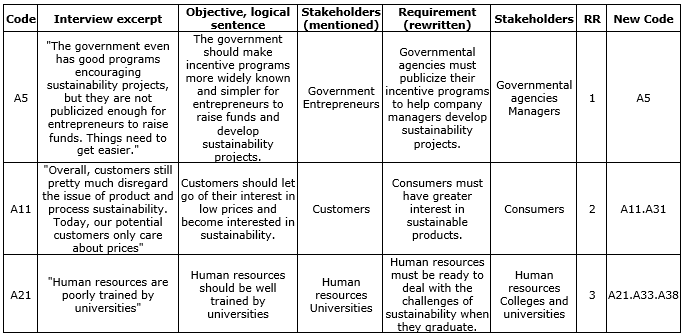

First, excerpts containing encouraging or discouraging factors for achieving sustainability goals were sought in each interview transcribed. These excerpts were codified to ensure that the original information was traceable and preliminarily rephrased into objective, logical sentences that connected the stakeholders mentioned with the factors. Subsequently, the sentences were rewritten as requirements using standardized technical language, and the stakeholders were identified. Redundant requirements were eliminated, their repetition rate (RR) recorded, and their respective codes grouped up. Chart 3 shows examples of the excerpts from the interview with the small manufacturer of cleaning products.

Chart 3. Conversion of excerpts into requirements for the HCP Small manufacturer

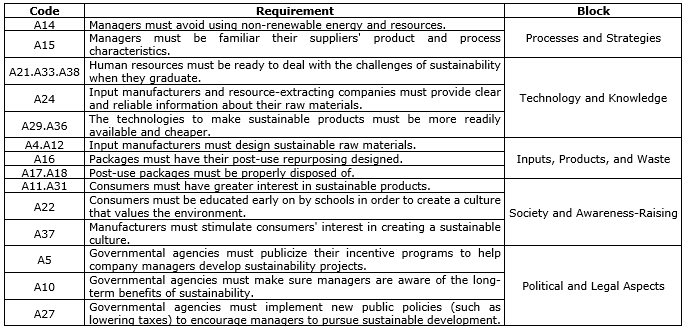

Some categories have emerged during the previous steps, being possible to group them as requirements related to: i) Processes and Strategies; ii) Technology and Knowledge; iii) Inputs, Products, and Waste; iv) Society and Awareness-Raising; and v) Political and Legal Aspects. Chart 4 containing the partial list of the HCP Small manufacturer’s requirements grouped them into those five categories/blocks.

Chart 4. Partial list of HCP Small manufacturer requirements, grouped into blocks

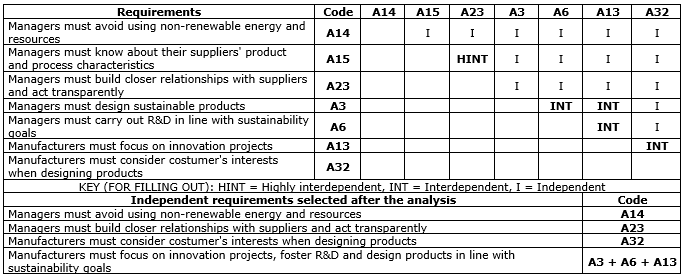

The following procedure aims to eliminate interdependent requirements to reduce the number of items that will be evaluated by the interviewees. Requirements were evaluated two by two in a square grid, per category of requirements for each interviewee. The independence between the requirements was analyzed for each cross-referencing. Three different rates were used, namely: (HINT) highly interdependent requirements; (INT) interdependent requirements; and (I) independent requirements. The least mentioned requirements (RR column in Chart 3) were eliminated or grouped when relationships were considered very interdependent or interdependent.

Because the purpose of this stage was to generate a minimum list of requirements, the decision to eliminate or group requirements was made on a case-by-case basis. Subsequently, independent requirements were once again grouped in blocks for each interviewee, and a final analysis was conducted to make sure that no interdependent requirements were selected. For illustration purposes, Figure 4 shows the requirements in the ‘Processes and strategies’ block for the HCP Small manufacturer in the square grid and the list of independent requirements selected after the two-by-two analysis.

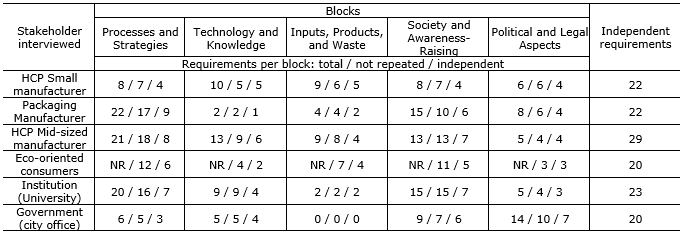

As a result of the steps, it was possible to reduce the requirements amount in 46% for the HCP Small Manufactures, 56% for the Packaging Manufacturer, 52% for the HCP Mid-sized manufacturer, 60% for the Institution (University) and 41% for the Government (city office). Table 1 shows the overall number of requirements generated, not repeated and independent, sorted by block and for each stakeholder interviewed. The last column contains the remaining requirements to be weighted by the stakeholders.

Figure 4. Evaluation of requirements interdependence inside HCP Small manufacturer ‘Processes and strategies’ block

Table 1. Number of independent requirements per block for each stakeholder

The last step of this stage is to rate the importance of each requirement. The stakeholder's independent requirement list was emailed to the respective interviewees, and they were asked to rate the importance of every requirement. A Likert-type scale was used, with an interval of integers ranging from 1 to 9, respectively representing little important and very important.

After the data were weighted, all (primary source) interviewees were asked how difficult it had been for them to evaluate and rate importance levels for their respective lists, which contained at least 20 and at most 29 requirements. No respondents said they had found it difficult. Therefore, the weighting was considered valid, considering the number of selected requirements was appropriate and did not lead to errors in the respondent's assessment process.

Eco-oriented consumers' requirements were obtained from the previous work of Marx et al. (2010). They made a closed-ended questionnaire available online and used the same scale adopted in this study. The requirements list in that study contained all of the non-recurring requirements, but they did not analyze the interdependencies between them.

3.4 Interfaces analysis

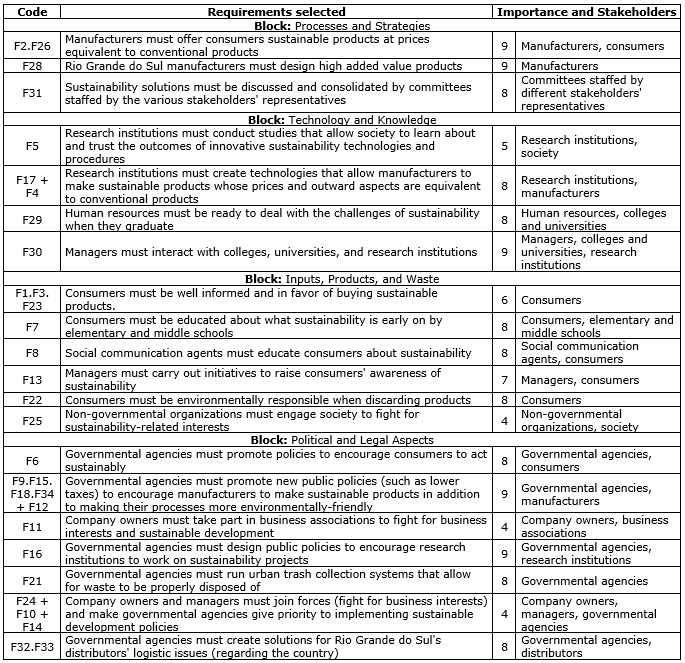

The first step in this stage is the selection of the most important requirements for each stakeholder from the requirement lists obtained in the previous stage. In this study, we chose to select 20 top-scoring requirements from each stakeholder to build the maps. These requirements were organized in a chart with the codification and the stakeholders related to them. To exemplify, chart 5 shows the 20 requirements from the standpoint of the government (city office) representative used to build the map shown in Chart 5.

Chart 5. List of 20 top-scored requirements to the government (city administration)

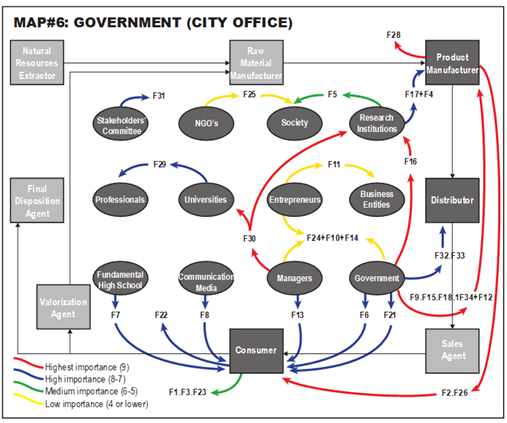

Figure 5 shows the map of the product system scenario containing the stakeholders' interfaces from the standpoint of a governmental agency's (city office) representative. The map shows the city representative referred to only three parties directly involved in the products' lifecycle (squares): product manufacturers, distributors (which were not mentioned in the other interviews), and consumers. The other stakeholders directly involved with the product system lifecycle were not mentioned in the interview and appear in light-colored squares. The interviewee referred to 12 parties that were indirectly involved (oval shapes), including: non-governmental organizations (NGOs), company owners, business associations, and social communication agents, which were not mentioned in the other interviews. The ratio between the parties directly and indirectly involved is inversely related to the consumers' opinion. It is possible to observe lines that move from different stakeholders towards a requirement (F24+F10+F14: Company owners and managers must join forces (fight for business interests) and make governmental agencies give priority to implementing sustainable development policies), thereby suggesting that managers, company owners, and governmental agencies need to cooperate for that requirement to be fulfilled, which creates a three-way interface between the stakeholders. The highest number of interfaces found connects other stakeholders to consumers, who are impacted by highly important requirements that need the action of other parties.

Figure 5. Map of interfaces from the government perspective (city office)

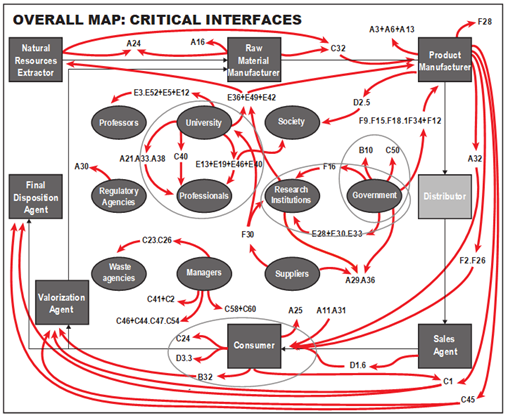

Other five maps, one for each stakeholder, were obtained using the same procedure. Finally, an overall map of the HCP system's scenario containing the critical interfaces between the stakeholders was drawn. The operation was performed under the assumption that a respondent would assign the highest importance to a given requirement because said requirement is the most critical for that stakeholder to achieve sustainability goals. Hence, to put together the overall map, only requirements rated 9 by each of the stakeholders' representatives interviewed was used. Figure 6 shows the overall map of the HCP system's scenario containing the critical interfaces between the stakeholders. Some recurring relationships were detected in the individual maps and marked with dashed circles in the overall map. These can be considered critical relations in the product system, pointed by more than one stakeholder/interviewee.

Figure 6. Map of critical interfaces between parties in the HCP system's lifecycle

Legend - A. Product Small Enterprise manufacturer; B. Packaging Manufacturer; C. Product Medium Enterprise Manufacturer; D. Green Consumers; E. University; F. Government

A few comments can be made about the six maps containing the interfaces and the overall map, which may be considered to visually represent the stakeholders' global value chain:

-

The maps containing the interfaces between the parties involved in the HCP system's lifecycle (from the standpoint of the six stakeholders interviewed) differ from one another. The number of stakeholders varied from map to map both in terms of lifecycle phases and the parties indirectly involved;

-

The interviewee who noticed and mentioned most of the agents directly involved in the lifecycle phases was the Packaging manufacturer's representative;

-

The interviewees from the city administration and university were the ones who noticed and mentioned most of the parties indirectly involved with the products' lifecycle;

-

Consumers were the ones noticing and mentioning the parties least indirectly involved with the products' lifecycle;

-

Overall, 21 agents indirectly involved with the products' lifecycle were identified: social communication agents; agents involved in waste pick up; agents routinely dealing with sustainability; students; committees staffed by stakeholder representatives; different stakeholders; company owners; business associations; suppliers; managers; elementary and middle schools; colleges and universities; research institutions; control agencies; governmental agencies; non-governmental organizations; regulatory agencies; faculty members; human resources; and society;

-

Out of all the parties directly involved in the product system lifecycle phases (which were included in the interview plan checklist), distributors were referred to only in the interview with the city administration's representative. Such stakeholder was not mentioned in the other interviews;

-

Out of the product system, stakeholders deemed to have critical interfaces and some were noticed and mentioned by a single interviewee, namely: (1) agents involved in waste pickup (urban foragers) were mentioned only by the representative of the HCP Mid-sized product manufacturer; (2) faculty members were mentioned only by the University's representative; (3) control agencies were mentioned only by the representative of the HCP Small product manufacturer.

The considerations above corroborate the idea that stakeholders are usually unable to see all of the other stakeholders and lifecycle phases of a product system. In this case, project team would have to keep in mind their analysis should go beyond the relationships seen by the very stakeholders.

Product manufacturers were the stakeholders to have the highest number of critical interfaces pointed out by the other interviewees (10 overall). Consumers were the second type of stakeholder to have the highest number of interfaces pointed out (9 overall). Colleges/universities and governmental agencies were assigned 6 critical interfaces each. Research institutions and managers were assigned 5 critical interfaces each. It indicates that product manufacturers and consumers are critical parties for sustainability to be achieved within a product system lifecycle and designers should have to pay greater attention to these stakeholders' requirements.

Out of all the critical interfaces, the highest number is related to requirements in blocks ‘Processes and strategies’ (9 overall) and ‘Technology and knowledge’ (8 overall). Six critical interfaces were pointed out from the ‘Political and legal aspects’, and, finally, blocks ‘Inputs, products, and waste’ and ‘Society and awareness-raising’ (5 overall). Even though the differences are not too big, it suggests that the highest number of critical factors for achieving sustainability can be related to processes and strategies or technology and knowledge, while the lowest number of critical factors is related to society and awareness-raising or political and legal aspects. It makes sense that technical aspects are still considered more critical in the case of HCP probably because they are chemical products with processes quite harmful to the environment, and so is the waste left over from their use. However, these observations are merely suppositions that need to be investigated.

Upon analyzing all of the critical interfaces, five requirements suggest the need for cooperation between the stakeholders, namely: (i) input manufacturers and resource-extracting companies to meet requirement A24 through a two-way interface; (ii) suppliers, governmental agencies, and research institutions to meet requirement A29.A36 through a three-way interface; (iii) consumers and product manufacturers to meet requirement C1 related to final disposal agents and repurposing agents through a four-way interface; (iv) resource-extracting companies and input manufacturers to meet requirement C32 related to product manufacturers through a three-way interface; (v) colleges/universities and research institutions to meet requirement E36+E49+42 related to resource-extracting companies and product manufacturers through a four-way interface.

The representatives from the HCP Small and HCP Mid-sized manufacturers agreed that sustainability depends on human resources prepared to deal with its challenges. The university's representative agreed, but argued that colleges and universities have a hard time training human resources and providing society with sufficient knowledge. In this gap, an opportunity is found and, at the same time, a risk to be worked on in a HCP system project: to build teams whose diverse backgrounds complement one another's skill sets, such as chemical, environmental, and manufacturing engineers, biologists, sociologists, economists, technologists, and others, to solve issues related to sustainable development.

The perceptions achieved from the study are related to a south Brazil HCP manufacturing and consumption system and may not be the same from other places. It also contemplates few stakeholders and interviewees; therefore, the critical interfaces cannot be generalized or considered conclusive. The syntax created to graphically represent the stakeholders’ interfaces in a product system was easy to read. The maps demonstrate to be a good way to identify relations and revealed some clues that should be further investigated in future studies.

4. CONCLUSIONS

By pursuing the main purpose of this study, which was to apply a systematic procedure to identify the critical interfaces between parties involved in a product system's lifecycle phases, it was possible to obtain interesting information about the requirements and stakeholders interrelated in a Rio Grande do Sul HCP manufacturing and consumption system. The information obtained from applying the procedure to a case study made it possible to identify critical interfaces between parties directly and indirectly involved with lifecycle phases from the standpoint of six representatives from different groups.

The procedure provides a graphic view of the results through individual maps and an overall map containing stakeholder requirements and interfaces. By analyzing the maps particularities and similarities can be seen, such as the need for cooperation between the different stakeholders so a requirement may be met, or the agreement on factors that encourage or discourage the stakeholders with respect to achieving sustainability goals. Another example of information provided by the maps is that both product manufacturers failed to mention a single factor interrelated with sales agents in their interviews. However, it is from these agents that products get to consumers and boost economic development. It is the interface between manufacturers and sales agents that allows the former to get feedback on the consumers' demands and needs, and therefore make improvements to environmental, social, and economic aspects. These analyses once again lead us to opportunities and/or risks, which ultimately serve as input information for product system projects.

Additionally, the study's results engendered the hypothesis that stakeholders are usually unable to see all of the other parties involved in the phases of a product system's lifecycle. Overall, the interviewees mostly pointed out factors that impact the lifecycle phases in which they respectively conduct directly related primary or secondary activities. Product manufacturers and consumers were the stakeholders involved in the highest number of interfaces deemed critical for sustainability to be achieved.

Given this study's limitations, the results cannot be generalized especially because results could have possibly been different in case the parties directly involved with resource extraction, input synthesizing, and final disposal had been interviewed. However, once these limitations had been established and interviewees holding comprehensive views of the investigated product system's lifecycle had been chosen, the procedure proved suitable for finding general information about the system, following the logic of the product's global value chain. Therefore, it can be concluded that the requirements and critical interfaces obtained through the procedure are useful information about the system, and point out what a designer should focus on when designing a product system in case that scenario were considered to be true.

Suggestions for future studies include: applying the procedure proposed to all stakeholders in the HCP system; applying this procedure to other product systems to compare results and validate the procedure; applying this procedure using probability sampling when collecting data; and creating criticality indicators for the product system's sustainability.

ACKNOWLEDGEMENTS

We acknowledge the National Science and Technology Development Council (Conselho Nacional de Desenvolvimento Científico e Tecnológico – CNPq), for their support that made this study possible.

REFERENCES

Almeida, A. M. G. et al. (2009), Influência de argumentos ecológicos e de responsabilidade sócio-ambiental no comportamento de compra de jovens. In: Congresso Virtual Brasileiro de Administração, VI, 2009. Disponível em: http://www.convibra.com.br/2009/artigos/180_0.pdf. Acesso em: 21 fev 2019.

Azevedo, F. A.; Chasin, A. M. (2004), As bases toxicológicas da ecotoxicologia. São Paulo: Rima, 2004.

Brundtland Commission (1987), Brundtland report: our common future. World commission on environment and development. ONU. Disponível em: <www.un-documents.net/ocf-02.htm#I>. Acesso em: 29 set 2009.

Donaldson, K. M.; Ishii, K.; Sheppard, S. D. (2006), Customer value chain analysis. Research in Engineering Design, London, Vol. 16, pp. 174–183.

Dormer, P. (1995), Os significados do design: a caminho do século XXI. Bloco Gráfico, Porto Alegre.

Forty, A. (2007), Objetos de desejo: design e sociedade desde 1750. Cosac Naify, São Paulo.

Gil, A. C. (1991), Como elaborar projetos de pesquisa. Atlas, São Paulo.

Gomes, L. F. A. M.; Damázio, H. N. (1992) Minimização Heurística da Interdependência entre Critérios no Auxílio à Decisão. Uma Aplicação à Decisão sobre Seguro Ambiental para Transporte Rodoviário de Produtos Perigosos. Working paper, Departamento de Engenharia Industrial, PUC-Rio, Rio de Janeiro, outubro.

Hansen, C. T.; Andreasen, M. M. (2010), On the content and nature of design objects in designing. In: International Design Conference, 11, 2010, Cavtat-Dubrovnik. Proceedings of XXI IDC. Cavtat-Dubrovnik: Design Society, 2010. pp. 761-770.

Hauschild, M.; Jeswiet, J.; Alting, L. (2005), From lifecycle assessment to sustainable production: status and perspectives. CIRP Annals — Manufacturing Technology, 54: 1–21.

Instituto Akatu Pelo Consumo Consciente (2009), Consumo consciente: o que é?. Disponível em: <www.akatu.org.br>. Acesso em: 27 dez 2010.

Kazazian, T. (2005), Haverá a idade das coisas leves: design e desenvolvimento sustentável. SENAC, São Paulo.

Kota, S.; Chakrabarti, A. (2007), Use of DfE methodologies and tools – major barriers and challenges. In: International Conference on Engineering Design, 16., 2007, Paris. Proceedings of XVI ICED. Paris: Indian Institute of Science, 2007. (cd-rom)

Kotonya, G., Sommerville, I. (2000), Requirements engineering: process and techniques. John Wiley & Sons, Chichester.

Marx, A. M. (2009), Proposta de método de engenharia de requisitos para o desenvolvimento de produtos sustentáveis. Dissertação (Mestrado em Engenharia de Produção) – Universidade Federal do Rio Grande do Sul, Porto Alegre.

Marx, A. M.; Paula, I. C.; Sum, F. (2010), Sustainable Consumption in Brazil: identification of preliminary requirements to guide product development and the definition of public policies. Natural Resources Forum, United Nations, Vol. 34, No. 1, pp. 51-62.

McDonough, W.; Braungart, M. (2002), Remaking the way we make things: cradle to cradle. North Point Press, New York.

Mizuno, S.; Akao, Y. (1994), QFD: the customer–driven approach to quality planning and development. Asian Productivity Association, Tokyo.

Mourão, Y. B. (2006), Priorização de projetos de pesquisa e desenvolvimento na indústria do petróleo: uma aplicação da teoria dos prospectos. Faculdades Ibmec, Rio de Janeiro.

Noro, G. B. et al. (2010), Sustentabilidade: uma visão baseada em stakeholders. Anais do VI CNEG, UNIFRA, Rio de Janeiro.

Park, J.; Ha, S. (2012), Understanding pro-environmental behavior: A comparison of sustainable consumers and apathetic consumers. International Journal of Retail & Distribution Management, Vol. 40, No. 5, pp. 388-403.

Passos, A. C.; Santos, F. S. P.; Mello, F. P. (2008), O método de minimização heurística da interdependência entre critérios no auxílio à tomada de decisão aplicado à seleção de escolas. SPOLM, Rio de Janeiro.

Ribeiro, J. L. D.; Milan, G. S. (2004), Entrevistas individuais: teoria e aplicações. FEEng/UFRGS, Porto Alegre.

Ribeiro, J. L.; Echeveste, M. E.; Danilevicz, A. M. (2000), A utilização do QFD na otimização de produtos, processos e serviços. PPGEP/UFRGS, Porto Alegre.

Santos, A.; Rosa, I. M.; Giacomini, J. (2009), Proposição de um conceito de PSS (sistema produto + serviço) para o setor de produtos de limpeza multiuso. Anais do II SBDS, 2009, São Paulo. Disponível em: <http://portal.anhembi.br/sbds/ anais/SBDS2009-039.pdf>. Acesso em: 28 jan 2010.

Schendel, C.; Birkhofer, H. (2007), Implementation of design for environment principles and methods in a company – practical recommendations. Proceedings of XVI ICED, 16, 2007, Paris. Paris: Indian Institute of Science.

Silva, E. L.; Menezes, E. M. (2001), Metodologia da pesquisa e elaboração de dissertação. 3. ed. rev. atual. Laboratório de Ensino a Distância da UFSC, Florianópolis.

Strujak, D.; Vidal, C. M. S. (2007), Poluição das águas: revisão da literatura. Revista Eletrônica Lato Sensu, Guarapuava, ano 2, n. 1, p.11-26, julho, 2007.

Teixeira, S. M. L.; Cartonilho, M. M. (2007), Avaliação do nível de substâncias tensoativas nas águas do igarapé do Mindu como indicador de poluição para monitoramento ambiental. Anais do XXIV CBESA. Belo Horizonte: ABES.

Thackara, J. (2008), Plano B: o design e as alternativas viáveis em um mundo complexo. Saraiva, São Paulo.

Van Halen, C.; Vezzoli, C.; Wimmer, R. (2005), Methodology for product service system innovation. Assen, the Netherlands: Koninklijke Van Gorcum.

Vezzoli, C.; Manzini, E. (2008) Design for environmental sustainability. Springer, London.

Young, R. (2003), The requirements engineering handbook. Norwood: Artech House.

[1] The Akatu institute is a Brazilian non-profit NGO working to educate and engage society with respect to responsible consumption.

Received: 07 Dec 2018

Approved: 28 Dec 2018

DOI: 10.14488/BJOPM.2019.v16.n1.a12

How to cite: Paula, I. C.; Hoppe, D. A.; Marx, A. M. et al. (2019), “Procedure for identifying factors and interfaces that are critical in a sustainable product”, Brazilian Journal of Operations & Production Management, Vol. 16, No. 1, pp. 126-140, available from: https://bjopm.emnuvens.com.br/bjopm/article/view/735 (access year month day).