Hybrid project management for sociotechnical digital transformation context

Adriane Monteiro Cavalieri Barbosa

adriane.cavalieri@int.gov.br

National Institute of Technology, Ministry of Science, Technology, Innovations and Communications – INT/MCTIC, Rio de Janeiro, Rio de Janeiro, Brazil.

Manoel Carlos Pego Saisse

manoel.saisse@int.gov.br

National Institute of Technology, Ministry of Science, Technology, Innovations and Communications – INT/MCTIC, Rio de Janeiro, Rio de Janeiro, Brazil.

ABSTRACT

Goal: The path to implement Digital Transformation (DT) in modern industries is far from clear, particularly in Brazil. From the point of view of operations management, authors developed a Conceptual Framework (CF) to support DT implementation in Discrete Manufacturing Industries (DMI). The CF applies knowledge management, hybrid project management (HPM) and Sociotechnical values to implement DT, using New Product Development (NPD) as a ground. The work aims to depict the HPM approach of this CF.

Design / Methodology / Approach: this is a qualitative research based on a systematic literature review carried out over a period of five years. It was performed in the Web of Science database, applying PRISMA flowchart, to evaluate which project management models, addressed in the literature, are more suitable for DT implementation projects in light of sociotechnical and innovation-shared-values approach.

Results: A Hybrid “Stage-Gate – Agile - Design Thinking” project management model to support DT implementation in DMI. This is a preliminary proposal that can be explored in future empirical research.

Limitations of the investigation: Some quality papers may have been left out due to the research methodology.

Practical implications: The CF can be applied by professionals to support Digital Transformation while incorporating sociotechnical values and reducing the excessive technological bias in NPD projects.

Originality/Value: The authors propose a new Digital Transformation (DT) approach, named Sociotechnical Digital Transformation (SDT) and an HPM to support DT in light of a Sociotechnical approach.

Keywords: Conceptual framework; Hybrid project management; Sociotechnical digital transformation; Digital transformation; New product development; Innovation and Sociotechnical shared-values.

INTRODUCTION

VUCA is an acronym for volatility, uncertainty, complexity and ambiguity. Bennett and Lemoine (2014) give the following explanations for those terms. A volatile situation is usually unstable and unpredictable; change is a core issue, but it doesn’t include problems with complex structure; knowledge about the effects caused by key events is scarce. Uncertainty does not involve change as much as volatility; cause and effect may be well understood, however, there is lack of knowledge about the extent of the changes that can be triggered by the events that occur in the environment. Complexity refers to environments with a large number of connected parts that create an intricate network of information and procedures. Ambiguity occurs when ‘the basic rules of the game’ are not well understood or known. Knowledge about cause and effect relations is very scarce; therefore, it is difficult to form predictions about future events.

VUCA has forced organizations to embark in Digital Transformation in order to stay productive and competitive. Reis et al. (2018, p. 418) define Digital Transformation as “(…) the use of new digital technologies that enables major business improvements and influences all aspects of customers’ life”.

New digital technologies will redefine marketplace expectations by discontinuing technical standards and creating new forms of ownership (Nagy et al., 2016). Cyber-physical system, Cloud Computing, Real-time big data, Internet of Services, Internet of Things, Internet of knowledge, and Internet by and for People will embrace networks of humans, computers, knowledge, services and things in highly integrated systems (Yao et al., 2014). They will transform the manufacturing environment, employing digital networks to bring together humans, digital equipment, knowledge, services and the production process to allow the creation of individually customized products (Wang et al., 2017).

The impacts of disruptive digital technologies go far beyond operational efficiency gains, for example, they can improve product quality, promote new services, and convert products in services (IEL, 2018). Despite market expectations, Pereira et al. (2018) affirm that present academic literature shows that the main outcomes of the Industry 4.0 movement are still restricted to operational research tools (usually Linear Integral Mixed Programming), used to improve or reduce the energy consumption of specific devices.

The E-Digital (Brazilian Digital Transformation Strategy (MCTIC, 2018)) presents some challenges for Brazilian industries: high costs of the innovative activity (for 58.4% of the total industries and 61.3% of the ICT industries), excessive economic risks of implementing innovations (for 50.4% of the total industries and 42% of the ICT industries), and scarcity of appropriate funding sources for innovation (for 41.1% of all industries and 39.2% of ICT industries).

Brazilian manufacturers should review their modus operandi; for example, they should establish new management practices and strengthen their innovation activities in order to exploit the benefits of the complex transformational trends that are underway. Industry 2027 project (IEL, 2018, p. 12) sustain that “all productive systems will be coexisting with disruptive technologies in up to ten years. Although time is scarce, Brazilian industry can and should prepare for these coming changes in technology”.

Lopes et al. (2016, p. 16) affirm that, “Innovation management has been received increasing attention in the operations management field during the last years” and “It was observed that academics and managers interested in innovation management are directly influenced by practices from organizational strategy, project management, knowledge management, innovation typology and technological innovation” (p. 21).

This paper presents a Conceptual Framework (CF) related to the operational level, called PSD, where (P) stands for Product Evolution, (S) for Stakeholder-digital technology/ Knowledge Spiral and (D) for Driving cycle. The PSD framework aims to support the implementation of Digital Transformation (DT) in discrete manufacturing industries.

Knowledge is the focus of the PSD framework (Cavalieri and Saisse, 2019), as it uses Innovation and Sociotechnical shared values to support Digital Transformation (DT) throughout New Product Development (NPD) projects. In this sense, the PSD is based on two main management initiatives: (1) NPD knowledge management, which involves the active engagement of the stakeholders to boost knowledge absorptive capacity, in an open innovation environment, where people and technologies work together to support individual and organizational learning and improve decision making processes; and (2) the hybrid project management approach to manage the NPD, which is used as a ground to implement DT.

The PSD uses NPD projects as a means to implement DT, generating innovations other than those incorporated directly in the new product and that can be shared among the stakeholders.

In this paper, the authors aim to detail the hybrid project management (HPM) approach. The paper is structured as follows. The “PSD framework theoretical background to HPM approach” section shows some examples of innovation and sociotechnical values shared in DT context and some relationships and peculiarities in the hybrid project management approaches. The “Research methodology” section is in sequence. The “PSD conceptual framework – HPM initiative” result section describes the hybrid project management model of the PSD conceptual framework. Finally, the “Final considerations” present a general evaluation of the present research work.

PSD FRAMEWORK THEORETICAL BACKGROUND TO HPM APPROACH

Innovation and sociotechnical values shared in DT context

According to Lichtenthaler (2017), organizations in a DT environment should implement shared value innovation integrating social and economic dimensions based on different innovation types, such as product innovation, process innovation, service innovation, business model innovation, organization innovation and management innovation. From the set of innovation types cited by Lichtenthaler (2017) the three more closely related to the PSD model are:

-

Product innovation, strengthening organization competitiveness while solving societal needs and challenges;

-

Process innovation, enhancing the competitive position of the organization, improving quality, lowering the costs associated to the product and/or service and reducing time to market;

-

Management innovation, generating and implementing tools that will change the management practices. For that innovation type, Lichtenthaler (2017) emphasizes that closer collaboration with suppliers may form clusters and contribute to societal issues.

Since the acceptance and diffusion of digital technologies depends on social innovation, excessively technology-oriented innovation approaches may restrain their potential (Kopp et al., 2016). DT initiatives should be viewed as an opportunity to address this issue and balance the responsibilities attributed to humans and machines according to the Sociotechnical approach (Mumford, 2006).

The sociotechnical approach proposed by Cherns (1987) and Trist and Murray (1993) aims to recognize and value differences among employee’s, their rights and needs compared to the demands of the non-human parts of the system, encourage their active participation and their influence on decisions, and emphasize team work and the sharing of information, knowledge and learning.

The sociotechnical approach regards DT environments as worldwide sociotechnical ecosystems, where systems are connected in networks, algorithms, people and industrial organizations (van Lier, 2015). The work and production attributes require: individuals’, teams’ and society’s well-being; user’s experiences with technological products; pleasure and fun when there is an interaction with technology and technological systems; and ethic and environmental justice (Brauner and Ziefle, 2015).

Besides that, sociotechnical approach should also consider the interactions, interdependencies and interrelated configurations between technology–human, organization–human and technology–organization. Some examples are: the distribution of activities between people and machine; high degree of operational freedom and human occupation at different activities; and the interdependencies between the horizontal dimension of the shop floor, the vertical dimension of the organization, and the supply chain (Dregger et al., 2016).

This is an opportunity to find new ways to integrate innovation and sociotechnical values into future industrial digitalized work systems. In this paper, the authors propose the use of a sociotechnical approach to create a new path for digital transformation, called Sociotechnical Digital Transformation (SDT).

Hybrid project management approach: relationships and peculiarities

Different approaches were proposed to manage NPD, from idea generation to launch. Saren (1984) analyzed the following ones: Departmental-stage models, Activity-stage models and Concurrent engineering, Cross-functional models, Stage-gate models, Conversion process models, Response models and Network model. Saren (1994) believed that the Network model would be a potentially relevant proposition to NPD process. “This approach is very useful for analyzing individual cases of NPD by mapping out the changing roles of the actors and the dynamic structure of the network, but it says little about the activity and resource inputs themselves, which are at least described by the stages models” (Saren, 1994, p. 637).

The stage-gate model has become popular; however, some authors claim that it is not suitable for innovation projects despite its documented advantages (Guimarães et al., 2014). Cooper and Sommer (2018) affirm that stage-gate model is too linear and rigid, which inhibit proactive responses to changes during the development process, such as returning to early phases to correct errors, which is viewed as an exception that should be avoided. Despite that weakness, Leithold et al. (2015) identified different Stage-Gates to NPD processes in 49 German SMEs. Guimarães et al. (2014) affirm that it is possible to achieve time and cost reduction in a NPD by the combination of lean with the Stage-Gate.

Cooper (2016) explains that manufacturers are integrating Agile elements of development processes into their existing gating systems. The result is an Agile–Stage-Gate hybrid model. Hybrid models combine adaptive and predictive project life cycles: the project elements that are known or which have established requirements follow a predictive pattern and the elements that are still in evolution follow an adaptive pattern (PMI, 2017).

Sommer et al. (2015) explain that the Agile values expressed in the Agile Manifesto lays the foundations towards a different way to manage NPD projects. Cooper and Sommer (2016) argue that the Agile-Stage-Gate Hybrid model “(…) promises to be the most significant change to our thinking in terms of how new-product development should be done since the introduction of the current popular gating systems 30 years ago” (p. 513). They exemplify some benefits of the Agile-Stage-Gate Hybrid model, as more responsive to changing customer needs, which is critical when things change quickly; builds a voice-of-customer that is more proactive and effective than traditional methods; and deals with team members more directly.

Satpathy (2016) clarifies at the SBOK Guide - the Scrum Body of Knowledge – that, among Agile methods, the most popular methodology for the development and delivery of new products is Scrum. Based on work cycles of one to four weeks, called Sprints, where at least one tangible value should be created, Scrum proposes a simpler and more natural way of dealing with the intrinsic unpredictability of projects, emphasizing continuous learning and discoveries.

The Agile-Stage-Gate adopts a holistic view of the project, providing means to improve coordination and communication with stakeholders and agility in planning and executing activities through Sprints by Scrum (an Agile approach) (Cooper and Sommer, 2016).

Empirical evidence regarding the benefits of Agile–Stage-Gate in a technology-based product development project shows that the hybrid approach applied in product development projects leads to improvements in information accuracy, commitment and leadership (Conforto and Amaral, 2016). On the other hand, critical factors, such as team characteristics, people competencies, organizational culture, organizational structure, available resources, technology uncertainty, and market characteristics might affect negatively the adoption of the hybrid approach (Conforto and Amaral, 2016). In addition, studies revealed that non-IT companies have limited knowledge in terms of Agile methods, even in a turbulent environment; therefore, it is generally applied as a sub-part of large projects or programs, which are structured primarily according to traditional project management models (Spalek, 2016).

Another hybrid approach proposes a combination of Agile with Design Thinking, which emphasizes the importance of interaction with stakeholders. While the Agile approach emphasizes close stakeholder-developer collaboration in configuring and changing requirements, Design Thinking emphasizes the development of empathy.

Design Thinking provides a systemized design process that enables teams to investigate the stakeholders’ thoughts, feelings, experiences, and needs, to generate innovative solutions with economic benefits (Mahmoud-Jouini et al., 2016). It is best applied where the problem or opportunity to develop significant or radical innovations is not well defined, in quickly changing markets where the customer needs are uncertain.

Some researchers suggest that Design Thinking is a valuable resource for achieving the human-centered approach, in other words, a deep understanding of consumers' lives. Immersion sessions, where stakeholders’ experiences and points of view are exposed and compiled, are used to broaden the understanding of their behavior, needs and preferences (Luchs et al., 2016). Despite its advantages and benefits, Design Thinking has been criticized for generating more incremental rather than disruptive innovation. The iterative and creative dynamics proposed by this methodology may excessively extend the costs and schedule of the project, hindering member motivation (Kupp et al., 2017).

Carlgren et al. (2016) claim that when Design Thinking is applied in large organizations to support innovation work, it presents some difficulties related to the following themes: user focus, framing, experimentation, visualization, and diversity. Some challenges are the inadequacy of existing processes and structures, difficulties in implementing new ideas and concepts, threats to the current dynamics of power and different communication styles. Those authors also claim that challenges should be identified and treated as an opportunity to improve Design Thinking or to implement organizational change.

Grashiller et al. (2017) create a combination of the Design Thinking with Agile method in order to manage NPD in a cost-effective and time-efficient manner, based on perceptions of empathy and creative team concepts. Both Design Thinking and Scrum use interactions tools, such as self-organized and interdisciplinary teams, to integrate the stakeholders in the product creation process.

Mixing Scrum with Design Thinking results in the generation of smaller and more frequent preliminary product versions or potential solutions. While Scrum acts more effectively on the agility dimension with less impact on cost, Design Thinking allows a deep understanding of stakeholders’ needs, expectations and behaviors.

RESEARCH METHODOLOGY

The research methodology adopted in this study was qualitative systematic review (Webster and Watson, 2002). The research phases (identification, screening, eligibility and included are presented using the PRISMA flowchart “Preferred Reporting Items for Systematic reviews and Meta-Analyses” (Moher et al., 2009).

The section “PSD framework theoretical background to HPM approach” was subdivided into two subsections “Innovation and Sociotechnical values shared in DT context” and “Hybrid project management approach: relationships and peculiarities”, as explained below.

The “Innovation and Sociotechnical values shared in DT context” subsection exemplified shared innovation values and revealed the differences between the sociotechnical values up to the 1990s and the sociotechnical values in a DT environment, extending the previous Cavalieri and Saisse’s (2019) work. The objective was to highlight the need to share the innovation and sociotechnical values among stakeholders and create a new process of digital transformation called Sociotechnical Digital Transformation (SDT). The “Hybrid project management approach: relationships and peculiarities” subsection was based on a literature review guided by the central question: “To what extent can the project management models addressed in literature contribute to DT implementation?” The following objectives were proposed:

-

Objective 1: Investigate the project management models that deal with the implementation of Digital Transformation.

-

Objective 2: Explore disruptive digital technologies applications to support project management.

-

Objective 3: Investigate the innovative hybrid project management models.

-

Objective 4: Distinguish the peculiarities and relationships of hybrid project management models.

The research was based on:

-

The keywords: Stage-Gate, Agile project management, Design Thinking and Innovation;

-

The keywords were combined in different ways as “TOPIC” at the Web of Science (WoS) database;

-

The keywords’ filters were: New product, Product, Digital, and Big data;

-

Time constraint was five years;

-

Publications in English: peer review papers, proceedings papers, article in press;

-

Subject areas of interest at WoS were: management, business, engineering industrial, operations research management science and engineering manufacturing.

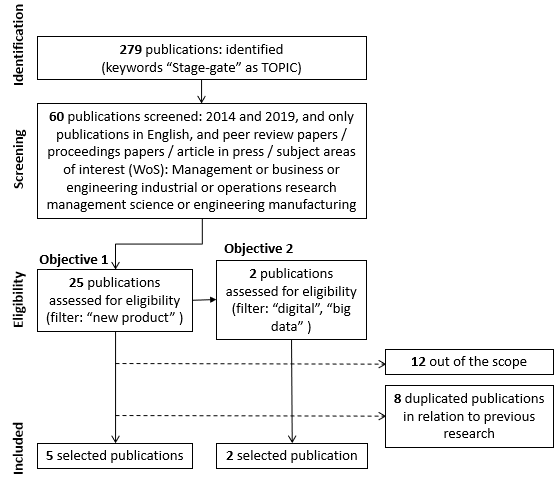

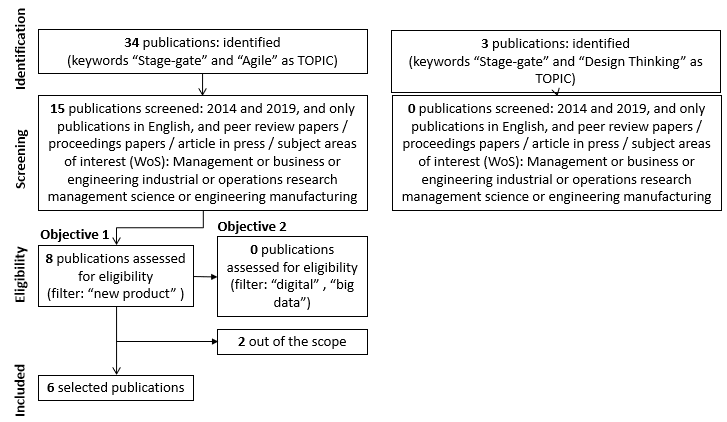

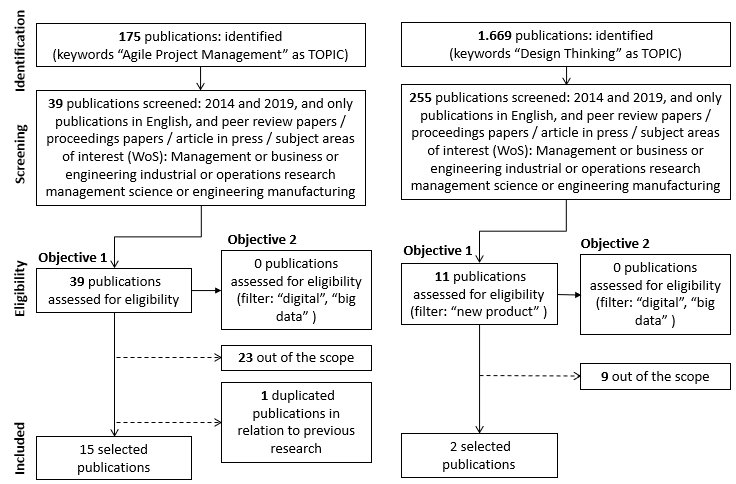

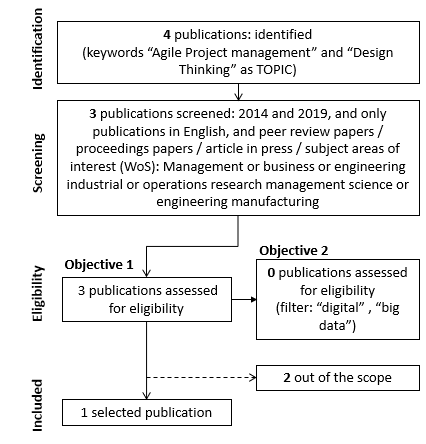

The research results are illustrated in Illustration 1 to 7.

Illustration 1. PRISMA - Stage-gate as TOPIC

Illustration 2. PRISMA - Stage-gate & Agile and Stage-gate & Design thinking

Illustration 3. PRISMA - Agile project management as TOPIC and Design thinking as TOPIC

Illustration 4. PRISMA - Agile project management & Design thinking as TOPIC

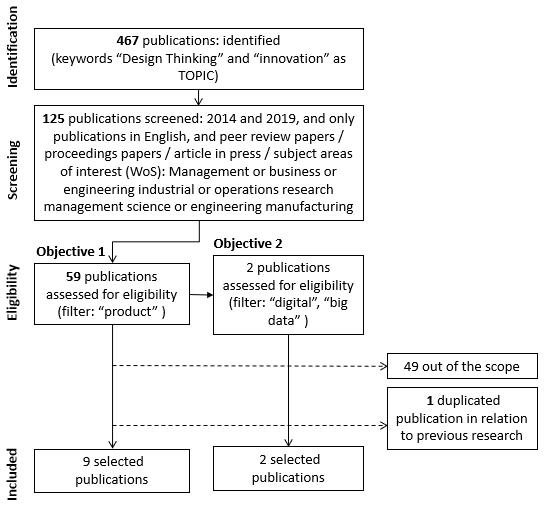

Illustration 5. PRISMA - Design thinking & Innovation as TOPIC

Illustration 6. PRISMA - Stage-gate & Innovation as TOPIC

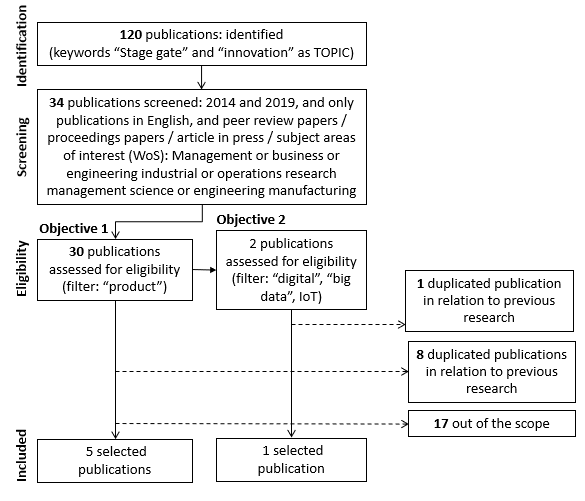

Illustration 7. PRISMA - Agile project management & Innovation as TOPIC

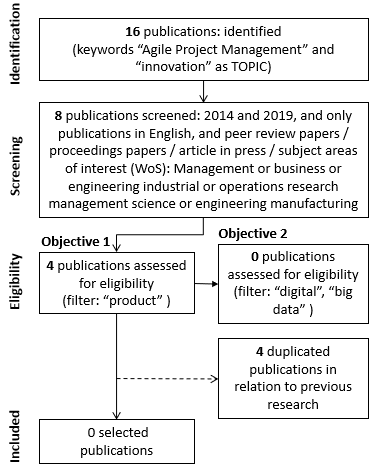

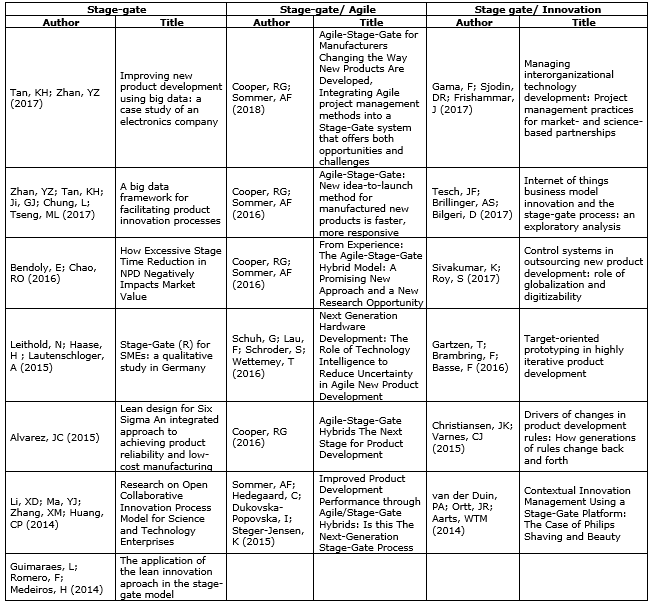

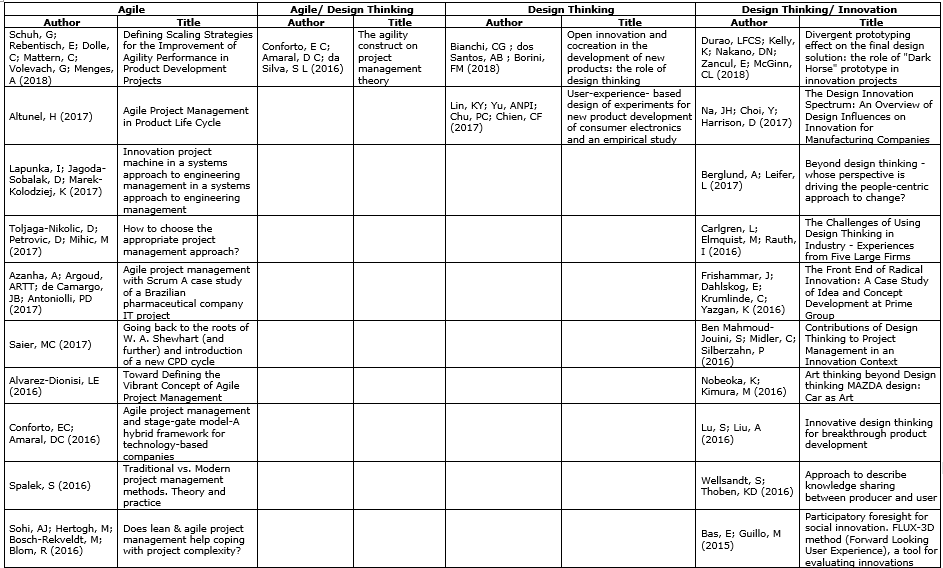

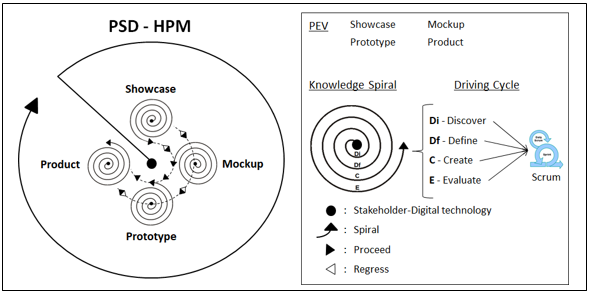

Forty-eight publications were select in total, as shown in Tables 1 and 2.

Table 1. Stage-Gate, Stage Gate & Agile, Stage Gate & Innovation

Table 2. Agile, Agile & Design Thinking, Design Thinking, Design Thinking & Innovation

As shown at Tables 1 and 2, some selected publications were outside of the scope of this paper, because they deal with construction engineering, computer systems and pharmaceutical industry, business models, designers’ work, and the outsourcing of NPD. The research resulted in the following findings, related to each intended Objective, as shown below:

Objective 1: Investigate the project management models that deal with the implementation of Digital Transformation.

- Findings 1: No project management model addressing the implementation of Digital Transformation was found.

Objective 2: Explore disruptive digital technologies applications to support project management.

- Findings 2: Some papers assessed the role of disruptive digital technologies in New Product Development process but did not address project management methodologies.

Objective 3: Investigate the innovative hybrid project management models.

- Findings 3: The project management models found did not employ hybrid Stage-Gate, Design Thinking and Agile in an integrative way.

Objective 4: Distinguish the peculiarities and relationships of the hybrid project management models.

- Findings 4:

a) The peculiarities and relationships among Stage-Gate, Agile and Design Thinking Hybrids were exposed in diverse combinations to reveal their suitability for the SDT implementation in Discrete Manufacturing Industries;

b) There is a gap in the research regarding methods that combine "Stage Gate” and “Design Thinking", as in Illustration 2;

b.1) Few references about hybrid Design Thinking methods in the Web of Science database were found. In this sense, a research review was conducted in Scopus. There was one paper selected because it criticized Design Thinking: “Why design thinking in business needs a rethink” from Kupp et al. (2017).

b.2) The authors resorted to the book: “Design Thinking: New Product Development Essentials from the PDMA” Luchs et al. (2016) to expand their study on Design Thinking applied in the NPD.

c) The research about hybrid models involving “Agile project management” and “Design thinking” resulted in only one paper, as shown in Illustration 4. In this way, the authors decided to complement the research in the Scopus database with the keywords "agile" and "design thinking" in the title, which resulted in 15 publications, most on them related to software development. One paper was found related to NPD:

c.1) Grashiller, M.; Luedeke, T.; Vielhaber, M. (2017). “Integrated approach to the agile development with design thinking in an industrial environment”. Proceedings of the International Conference on Engineering Design, ICED; Vol. 2, Issue DS87-2, 2017, pp. 239-2482; 1st International Conference on Engineering Design, ICED 2017; University of British Columbia (UBC) Campus Vancouver; Canada; 21 August 2017 through 25 August 2017.

d) The authors resorted to PMI (2017) – PMBOK Guide - to clarify the difference between the predictive and adaptive patterns that are proposed in hybrid project management models, and Satpathy (2016) – SBOK Guide - for a better understanding of Scrum.

PSD CONCEPTUAL FRAMEWORK – HPM INITIATIVE

Traditional project management approaches based on the waterfall methodology are not suitable for innovation projects within the scope proposed by the Sociotechnical Digital Transformation (SDT) approach at VUCA environments. As Bennett and Lemoine (2014) argue, agility is a key element to cope with volatility; information is critical to reduce uncertainty; restructuring internal operations is essential if the industry is to cope with the complexity of the external environment; the experimentation is necessary to reduce ambiguity.

Hybrid approaches seem to be more suitable to deal with innovation environments at the SDT context, as they combine predictive and adaptive patterns. The “Stage-Gate-Agile-Design Thinking” hybrid is aligned with the concerns about VUCA environments raised by Bennett and Lemoine (2014). For example: (1) the Stage-Gate approach proposes that the project should be viewed as a whole, as it facilitates the coordination and communication with other departments of the organization, other project developments, and with planning teams; (2) Sprints of the Agile approach do not provide such efficient coordination tools, but provide the agility and flexibility necessary for innovative projects, absorbing identified changes and responding quickly to unexpected events; and (3) Design Thinking is a valuable human-centered approach, as it aims to develop empathy among stakeholders, encouraging them to express their needs and expectations while evaluating whether the new product versions can meet them through experimentation on a variety of prototypes.

In this sense, the hybrid “Stage-Gate – Agile - Design Thinking” proposes a holistic view of the project, agile ways to deal with changes and a human-centered approach, emphasizing discoveries and continuous learning.

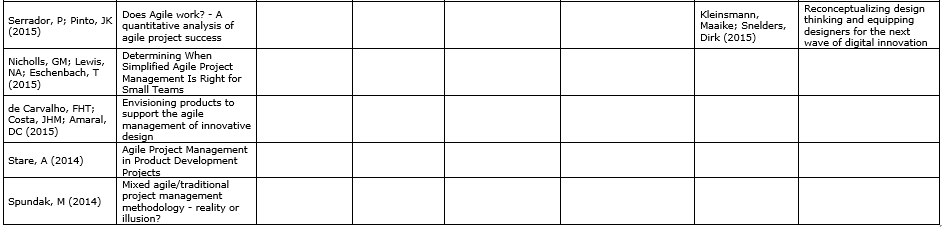

Cavalieri and Saisse (2019) developed a Conceptual Framework (CF) that embraces knowledge management and hybrid project management to drive the implementation of SDT at Discrete Manufacturing Industries. The CF is called PSD due to its main elements (P) Product Evolution, (S) Stakeholder-digital technology/ Knowledge Spiral, and (D) Driving cycle.

PSD is shown in Illustration 8.

Illustration 8. PSD conceptual framework Source: Cavalieri and Saisse (2019)

PSD employs a spiral to represent the dynamic movement of the stakeholders’ knowledge, which rotates around a central ax, sometimes moving away and sometimes approaching it. Along this path, the stakeholders’ knowledge, in light of Nonaka’s spiral (Finley and Sathe, 2013), is transformed from tacit to explicit, enabling the creation, transference and dissemination of new knowledge (Gao and Bernard, 2018; Finley and Sathe, 2013). There is a set of routines and processes related to knowledge acquisition, assimilation, transformation and exploration, in other words, the knowledge absorptive capacity that allows project teams to employ large amounts of information and knowledge and share it among different stakeholders, resulting in higher performance outcomes (Martin et al., 2016).

Sociotechnical Digital Transformation (SDT) demands an open innovation environment, where digital network technologies are used to connect stakeholders and organizations. The central ax represents the diverse actively engaged stakeholders and the disruptive digital technologies that support their decisions and enables major business improvements in light of the Sociotechnical approach. SDT implementation emphasizes interactions, interdependencies and interrelated configurations between technology–human to support stakeholders’ decisions. Stakeholders' active participation and their well-being are recognized, and the difference among them is valued. They have fun when they experiment the technological products to take their decisions.

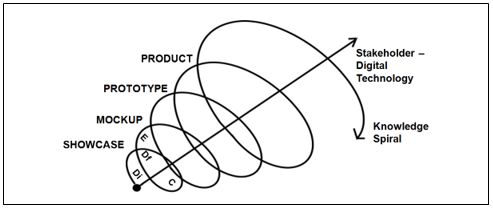

PSD allows the management of the NPD, which is used as a ground to implement SDT, through the hybrid project management (HPM) approach. The management process, named Product Evolution, is structured in four Evolution Moments: Showcase, Mockup, Prototype and Product. Each one of them progresses through a set of Driving Cycles, including Discovery (Di), Definition (Df), Creation (C), and Evaluation (E).

In this way, the PSD allows organizations to benefit from innovation processes in a broader sense, as the one proposed by Lopes et al. (2016, p. 16): “For many organizations, innovation is not just an alternative to present new products or increase their production capacity by changing their internal processes, but a way to influence and change the industry they belong”.

The present section details the HPM initiative as shown in Illustration 9.

Illustration 9. PSD - HPM initiative Source: By authors

The Product Evolution (PEv) is structured in four Evolution Moments (EM): Showcase, Mockup, Prototype, and Product. PEv, in light of Stage-Gate, intends to allow the macro view of NPD, the coordination between each EM and the integration among internal stakeholders, collaborators and external stakeholders.

Each EM aims to generate potential solutions departing from the knowledge made explicit by internal stakeholders and collaborators in an open innovation environment. Professionals from R&D, production, sales, finances, marketing, logistics, information technology, and human resource departments are considered internal stakeholders, while customers, users, start-ups, makers, suppliers, research organizations, university researchers, and consultants are viewed as collaborators. The external stakeholders are partners, competitors, intellectual property organizations, environmental organizations and other regulatory organizations. The internal stakeholders and collaborators participate actively in the PEv and the external stakeholders participate when invited by the internal stakeholders and/or collaborators.

PEv is detailed as follows:

(1) Showcase Moment – Internal stakeholders, collaborators and external stakeholder are stimulated to externalize identify and create their physical, emotional, cognitive and business requirements. Initial ideas about the product will be generated based on these identified requirements. Sketches and digital or physical mockups with few functions will work as “tasting versions” in the sense of a gustation, as they are conceived to create a basic experience and develop an initial understanding of the stakeholders´ requirements. Reactions, opinions and behavior are registered, integrated and analyzed. This is the moment to identify the SDT objectives, establish partnerships and formalize contracts.

(2) Mockup Moment - Internal and external stakeholders and collaborators use mockups to develop and share concepts already in line with the stakeholders’ needs and the SDT objectives, identified in the previous Showcase Moment. Mockups should not be detailed versions, nor be fully functional solutions. Their focus must be on providing an experience of the selected alternative or a set of key attributes of the product proposal. They may be tridimensional images, 3D printed, scale models, simulated models or virtual and augmented reality models. They should accelerate and encourage the creation of new ideas, allowing observation of stakeholders’ reactions while experiencing them.

(3) Prototype Moment – Detailing the product and the possibility of the experience occurs with tangible real solutions - prototype versions -, which are built based on the results collected from the previous experiences with the mockups. The internal stakeholders and collaborators experience the SDT.

(4) Product Moment – SDT goals are achieved and new product launch procedures are defined.

The active participation of internal stakeholders and collaborators in the NPD and the segmentation of the project in moments of evolution allow a gradual creation and gathering of knowledge about the new product. Their new information, ideas, knowledge, and opinions are recorded, integrated and analyzed to form potential solutions that will gradually bring the obtained results closer to the desired outcomes. The fit between successive EMs is achieved when the outcome of one Moment is a consequence of the potential solution that precedes it.

Each specific EM delivers different tangible values of potential solutions, as follow:

- Showcase Moment - The "tasting versions" have few functions. It can be made of low cost and alternative materials. The time required for the development is short, if compared with the following versions generated in the next moments; the time spent to form a good understanding of the stakeholders needs and their expectations can be quite long;

- Mockup Moment - The mockup versions are a bit more tangible. In this phase, the stakeholders should be able to experience, evaluate and validate certain technological characteristics of the proposed solution; the scope and development time required is significantly larger than that associated with the "tasting version";

- Prototype Moment - The prototype versions must be made of materials identical or very similar to those intended to be used on the final product. Stakeholders must be able to effectively experience fully functional solutions to evaluate and validate their performance; it should be able to stand performance tests. The scope, time and cost of development are usually the higher of the process.

While PEv determines the direction of the desired SDT implementation and the new product evolution until its launch, the Knowledge Spiral guides the transition between the EM, according to the information, and the new knowledge generated. The information and stakeholders’ knowledge are diverse in each EM and are supported by disruptive digital technologies, as cloud computing, real-time big data, internet of knowledge, and 3D printed and virtual and augmented reality models.

The active engagement of the internal stakeholders and collaborators across the PEv is essential to transform new knowledge into new practice, new products and to allow the internalization of explicit knowledge. The internal stakeholders and collaborators are mobilized and demobilized according to their distinct knowledge, motivations and responsibilities at each EM.

The observation, discussion, register and integration of new ideas occur simultaneously when stakeholders experience potential solutions at each EM. Alternative versions of product or parts are used as enablers of the creation process by the internal stakeholders and collaborators. The results of these experiences help to direct the most appropriate lines of action to deal with the problems, opportunities and challenges that arise at each Evolution Moment (EM).

Industries in SDT transition should be evaluated by digital maturity models to support their strategic decisions and action plans to improve their digital technology level (Schumacher et al., 2016). In this sense, while knowledge is shared among stakeholders, it is an opportunity to reflect on the current capabilities and take decision on strategies and plans regarding the level of digital maturity of Discrete Manufacturing Industries (DMI), considering sociotechnical initiatives according to its needs and the needs of its partners.

The current and desired level of digital maturity considering sociotechnical approach should be discussed in a shared way to be transformed into information, which, in turn, will be transformed into knowledge throughout the PEv.

This is necessary to align digital initiatives with the available digital technologies, resources, capabilities (Schumacher et al., 2016) and current internal stakeholders and collaborators’ knowledge. The Showcase Moment’s digital maturity level will determine which digital initiatives should support them. Subsequent EM requires higher level of digital maturity considering sociotechnical initiatives that DMI should pursue, implement and share with their partners during the NPD project.

Each EM is related to a specific managerial context (complexity and broadness of the potential product solutions are distinct, and so are its costs, resources, risks and times) that will evolve until the commercialization structure of the product is completed and the SDT is implemented.

The Driving Cycle (Dc) is an immersed, flexible, iterative and agile approach, in light of Design Thinking and Agile-Scrum. This is structured with four phases as Discovery – Definition – Creation – Evaluation to manage the distinct context of each EM. The coherence between the EMs is guaranteed by the Dc, which is repeated for each EM. The end of each Dc must correspond to a potential product version that materializes the stakeholders’ knowledge identified and modeled during the EM. The ideas and knowledge generated in each Dc may lead to corrections in previous versions; therefore, PSD should also be able to retreat to a previous EM in such situations.

The Driving Cycle works as follows:

(1) Discovery - Aims to identify which stakeholders and collaborators would be required to participate in the innovation process and which digital technologies can be used to support it. The stakeholders’ information, ideas, knowledge, motivations and opinions are mapped according to the EM in question. Interviews, meetings, workshops, video conference, video sharing, and social media will be intensively used to form a detailed understanding of the stakeholder's values and behaviors. The different stakeholder's visions should be registered, integrated and summarized to be analyzed in the Definition phase.

(2) Definition – Once the information about stakeholders, collaborators and their contexts are summarized, they should be analyzed to identify the problems and opportunities that will give rise to innovation and the most relevant needs and perceptions among those that have been raised previously. The different ideas raised in the first phase will be analyzed in order to identify which ones will be chosen to be worked in the Creation phase.

(3) Creation - Communication must be strengthened so that internal stakeholders and collaborators can accumulate and organize new knowledge efficiently and create tangible alternative solutions as soon as possible with the support of digital technologies. The stakeholders and collaborators experience the "Tasting Versions", "Mockups" or "Prototype" (depending on the Evolution Moment) and externalize their opinions and ideas that should be properly compiled. In this sense, ideas and potential solutions are used to mobilize, share, expand and internalize new knowledge, generating innovation and sociotechnical initiatives.

(4) Evaluation - Decision on whether to proceed to the next EM is taken in this phase, which is positioned between every two contiguous EMs. It aims to ensure the continuity and fit between EMs. The evaluation of the tangible potential solutions in relation to the purpose of the respective EM will determine the advance to the next EM or a retreat to the beginning of the current EM.

In light of the Agile project management approach, each phase of the Driving Cycle should be structured based on Sprints, delivering tangible values to stakeholders. The completion of each Sprint includes the plan for the next Sprint.

The tangible value of potential solutions can be evaluated, tested, inspected and released. Possible product solutions should fit the interfaces and interdependencies with other innovations that are in place or that are being developed in the organization, which, in turn, must be aligned with the SDT goals.

FINAL CONSIDERATIONS

The PSD Conceptual Framework intends to guide an innovation process that happens in line with a deep understanding of the needs and behaviors of the stakeholders. It demands the active participation of the stakeholders throughout the creation process, with the implementation and application of disruptive digital technologies to obtain functional and valuable potential versions since its earliest stages.

The PEv provides a macro view of its progress and a better coordination and communication among the project internal stakeholders, collaborators and external stakeholders. The "Discover-Define-Create-Evaluate" Driving Cycle provides an adequate-immersed and flexible management alternative for each Evolution Moment. It occurs within the Evolution Moments, when the stakeholders’ knowledge is materialized in a product version with the support of disruptive digital technologies. At the end of each Driving Cycle, the project team may decide to go ahead, proceeding to the next Evolution Moment in the knowledge spiral or to retreat to the prior Evolution Moment to adjust a previous path or define a new one.

The Driving Cycle is repeated along the knowledge spiral, ensuring the alignment between consecutive Evolution Moments: each Evolution Moment must start from the solution developed in the previous one. The potential product solutions should be aligned with the SDT goals and should fit the interfaces and interdependencies with other innovations types (production process innovation and management innovation), which happen in parallel, because of their inter-relationships.

The proposed PSD-HPM seeks to defy the rigid characteristics of the traditional project management models, when considers PEv and Driving Cycle jointly, and to strength the freedom and the creativity of stakeholders by the Knowledge Spiral as a guidance for the creative and interactive processes.

Academics should explore the PSD proposal in future empirical research, while managers could take it as a reference to Sociotechnical Digital Transformation.

REFERENCES

Bennett, N.; Lemoine, G. J. (2014). “What a difference a word makes: understanding threats to performance in a VUCA world”, Business Horizons, Vol. 57, No. 3, pp. 311-317.

Brauner, P.; Ziefle, M. (2015). “Human factors in production systems”, In: Brecher C. (eds) Advances in Production Technology. Lecture Notes in Production Engineering. Springer, Cham, pp. 187-199.

Carlgren, L.; Elmquist, M.; Rauth, I. (2016). “The challenges of using design thinking in industry - experiences from five large firms”. Creativity and Innovation Management, Vol. 25, No 3, pp. 334-362.

Cavalieri, A.; Saisse, M. C. P. (2019). “NPD project as an impulse for digital transformation in light of sociotechnical design principles”. Revista Científica da Academia Militar - Proelium Journal, Série VIII, No. 2.

Cherns, A. (1987). “Principles of sociotechnical design revisited”, Human Relations, Vol. 40, pp. 153–161.

Conforto, E. C.; Amaral, D. C. (2016). “Agile project management and stage-gate model - a hybrid framework for technology-based companies”. Journal of Engineering and Technology Management, Vol. 40, pp. 1–14.

Cooper, R. G. (2016). “Agile-stage-gate hybrids: the next stage for product development”, Research-Technology Management, Vol. 59, No 1, pp. 21-29.

Cooper, R. G.; Sommer, A. F. (2016). “The agile–stage-gate hybrid model: a promising new approach and a new research opportunity”, Journal of Product Innovation Management, Vol. 33, No 5, pp. 513-526.

Cooper, R. G.; Sommer, A. F. (2018). “Agile–stage-gate for manufacturers”, Research-Technology Management, Vol. 61, No 2, pp. 17-26.

Dregger, J.; Niehaus, J.; Ittermann, P.; Hirsch-Kreinsen, H.; ten Hompel, M. (2016). “The digitization of manufacturing and its societal challenges”, 2016 IEEE International Symposium on Ethics in Engineering, Science and Technology (ETHICS), Vancouver, Canada, May 13-14.

Finley, D.; Sathe, V. (2013). “Nonaka’s SECI framework: case study evidence and an extension”, Kindai Management Review, Vol. 1, pp. 59-68.

Gao, J.; Bernard, A. (2018). “An overview of knowledge sharing in new product development”, International Journal of Advanced Manufacturing Technology, Vol. 94, pp. 1545–1550.

Grashiller, M.; Luedeke, T.; Vielhaber, M. (2017). “Integrated approach to the agile development with design thinking in an industrial environment”. Proceedings of the International Conference on Engineering Design, ICED; Vol. 2, Issue DS87-2, 2017, pp. 239-2482; 1st International Conference on Engineering Design, ICED 2017; University of British Columbia (UBC) Campus Vancouver; Canada; 21 August 2017 through 25 August 2017.

Guimarães, L.; Romero, F.; Medeiros, H. (2014). “The application of the lean innovation aproach in the stage-gate model”. 2nd International Conference on Project Evaluation, ICOPEV 2014, Guimarães, Portugal, pp. 109-113.

Instituto Euvaldo Lodi - IEL (2018). “Industry 2027 - risks and opportunities for Brazil in the face of disruptive innovations”, Final report “Building the future of Brazilian industry, Vol. 1 - Disruptive technologies and industry: current situation and prospective evaluation”, IEL, Brasília.

Kopp, R.; Howaldt, J.; Schultze, J. (2016). “Why Industry 4.0 needs workplace innovation: a critical look at the German debate on advanced manufacturing”, European Journal of Workplace Innovation, Vol. 2, No. 1, pp. 7-24.

Kupp, M.; Anderson, J.; Reckhenrich, J. (2017). “Why design thinking in business needs a rethink”, MIT Sloan Management Review; Cambridge, Vol. 59, No. 1, pp. 42-44.

Leithold, N.; Haase, H.; Lautenschloger, A. (2015). "Stage-Gate® for SMEs: a qualitative study in Germany", European Journal of Innovation Management, Vol. 18, No. 2, pp. 130-149.

Lichtenthaler, U. (2017). “Shared value innovation: linking competitiveness and societal goals in the context of digital transformation”, International Journal of Innovation and Technology Management, Vol. 14, No. 4.

Lopes, A. P. V. B. V.; Kissimoto, K. O.; Salerno, M. S.; Carvalho, M. M.; Laurindo, F. J. B. (2016). “Innovation management: a systematic literature analysis of the innovation management evolution”, Brazilian Journal of Operations & Production Management, Vol. 13, No. 1, pp. 16-30.

Luchs, M. G.; Swan, S.; Griffin, A. (2016). “Design Thinking: New Product Development Essentials from the PDMA”. Product Development and Management Association's (PDMA) Guide. John Wiley & Sons, New Jersey.

Mahmoud-Jouini, S. B.; Midler, C.; Silberzahn, P. (2016). “Contributions of design thinking to project management in an innovation context”, Project Management Journal, Vol. 47, No. 2, pp. 144-156.

Martin, M.; Reinhardt, R; Gurtner, S. (2016). “Stakeholder integration in new product development: a systematic analysis of drivers and firm capabilities”. R&D Management, Vol. 46, No. 3, pp. 1095-1112.

Ministro da Ciência, Tecnologia, Inovações e Comunicações – MCTIC (2018). Estratégia Brasileira para a Transformação Digital (E-Digital). Brasília: MCTIC; 2018.

Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D. G. (2009). “Preferred reporting items for systematic reviews and meta-analyses: the PRISMA statement”, Annals of Internal Medicine, Vol. 151, No. 4, pp. 264–269.

Mumford, E. (2006). “The story of socio-technical design: reflections on its successes, failures and potential”, Information Systems Journal, Vol. 16, pp. 317–342.

Nagy, D.; Schuessler, J.; Dubinsky, A. (2016). “Defining and identifying disruptive innovations”, Industrial Marketing Management, Vol. 57, pp. 119–126.

Pereira, G. B.; Santos, A. P. L.; Cleto, M. G. (2018). “Industry 4.0: glitter or gold? A systematic review”, Brazilian Journal of Operations & Production Management, Vol. 15, No 2, pp. 247-253.

Project Management Institute - PMI (2017). Project Management Body of Knowledge. Newtown Square, PA: Project Management Institute, 6 Edition.

Reis J.; Amorim M.; Melão N.; Matos P. (2018) “Digital transformation: a literature review and guidelines for future research”, In: Rocha A.; Adeli H.; Reis L.P.; Costanzo S. (eds). Trends and Advances in Information Systems and Technologies. WorldCIST'18 2018. Advances in Intelligent Systems and Computing, Vol. 745. Springer, Cham, pp. 411-421.

Saren, M. A. (1984). “A classification of review models of the intra-firm innovation process”. R&D Management, Vol. 14, No. 1, pp. 11–24.

Saren, M. A. (1994). “Refraining the Process of New Product Development: from “Stages" Models to a "Blocks" Framework”. Journal of Marketing Management, Vol. 10, pp. 633-643.

Satpathy, T. (2016). A Guide to the Scrum Body of Knowledge (SBOK™ Guide). SCRUMstudy, available from https://www.scrumstudy.com/SBOK/SCRUMstudy-SBOK-Guide-2016-Portuguese.pdf (access Nov 2017).

Schumacher, A.; Erol, S.; Sihn, W. (2016). “Maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises”, Procedia CIRP, No 52, pp.161-166.

Sommer, A. F.; Hedegaard, C.; Dukovska-Popovska, I.; Steger-Jensen, K. (2015). “Improved product development performance through agile/stage-gate hybrids: the next-generation stage-gate process?”, Research-Technology Management, Vol. 58, No 1, pp. 34-45.

Spalek, S. (2016). “Traditional vs. modern project management methods - theory and practice”. Smart and Efficient Economy: Preparation for the Future Innovative Economy, 21st International Scientific Conference, Brno University Technology, Faculty of Business & Management, Brno, Czech Republic 19-20.05.2016, pp. 499-506.

Trist, E.; Murray, H. (1993). The social engagement of social science: a tavistock anthology - the socio-technical perspective. University of Pennsylvania Press, Vol. 2.

van Lier, B. (2015). “Advanced manufacturing and complexity science”, 19th International Conference on System Theory, Control and Computing. ICSTCC 2015 - Joint Conference SINTES 19, SACCS 15, SIMSIS 19, art. no. 7321307, pp. 285-290.

Wang, Y.; Ma, H. S.; Yang, J. H.; Wang, K. S. (2017). “Industry 4.0: a way from mass customization to mass personalization production”, Advances in Manufacturing, Vol. 5, No 4, pp. 311-320.

Webster, J.; Watson, R. T. (2002). “Analyzing the past to prepare for the future: writing a literature review”, MIS Quarterly, Vol. 26, No. 2, pp. xiii-xxiii/June.

Yao, X.; Jin, H.; Zhang, J. (2014). Towards a wisdom manufacturing vision. International Journal of Computer Integrated Manufacturing, Vol. 28, No. 12, pp. 1291–1312.

Received: 15 Dec 2018

Approved: 15 Apr 2019

DOI: 10.14488/BJOPM.2019.v16.n2.a12

How to cite: Cavalieri B., A. M.; Saisse, M. C. P. (2019), “Hybrid project management for sociotechnical digital transformation context”, Brazilian Journal of Operations & Production Management, Vol. 16, No. 2, pp. 316-332, available from: https://bjopm.emnuvens.com.br/bjopm/article/view/691 (access year month day).