Providing a Model for Ranking Suppliers in the Sustainable Supply Chain Using Cross Efficiency Method in Data Envelopment Analysis

Mohammad Hashemi Tabatabaei

tabatabaei.mhm@gmail.com

Department of Industrial Management, Faculty of Management and Accounting, Allameh Tabataba’i University, Tehran, Iran.

Ardeshir Bazrkar

ardeshir.Bazrkar@gmail.com

Department of Industrial Management, North Tehran Branch, Islamic Azad University, Tehran, Iran.

ABSTRACT

Goals: This research seeks to identify the basic indices of sustainability in three dimensions (economic, social and environmental) in the Iranian automotive industry suppliers by reviewing previous research and ranking the suppliers using a cross efficiency approach. In this paper, the performance and ranking of sustainable supply chain suppliers are evaluated by presenting a secondary objective model in terms of cross efficiency.

Design / Methodology / Approach: In the first step of this research, a preliminary screening of the identified criteria is carried out. the data on the final criteria is collected using a questionnaire. Finally, the evaluation and ranking of suppliers in sustainable supply chain of the automotive industry in Iran is done by the cross-efficiency model presented in this paper.

Results: The results showed that, according to the criteria of the triple profit model (including 3 dimensions, 7 criteria), supplier No. 8 was identified as the most efficient decision maker unit (DMU) among 12 suppliers of Iran Khodro Company.

Limitations of the investigation: The main constraints include the timeliness of information gathering and the lack of cooperation of suppliers in providing information.

Originality / Value: Using the cross efficiency model in data envelopment analysis technique in the field of evaluating supplier performance is a very practical and unrestricted approach.

Keywords: Sustainable Supply Chain; Supplier Ranking; Cross- efficiency; Automotive Industry.

1. INTRODUCTION

The term sustainable development is defined by the World Commission on Environment and Development as development that seeks to meet the needs of the present without compromising the ability of future generations to meet their own needs (Camioto et al., 2017). In a general view, addressing supply chain management can be an important step towards improving sustainability in business because supply chain management involves all stages of production from the beginning to product lifetime management. Therefore, combining sustainability issues and supply chain management can have a huge impact on business sustainability. Therefore, issues such as green chain management and supply chain management are addressed in the literature. The main objective in sustainable supply chain management is to focus on environmental, economic and social issues at all stages of the production of a product, including the purchase of raw materials, production, distribution and sale of products. In the last decades, green and sustainable supply chain management practices have been developed, trying to integrate environmental concerns into organizations by reducing unintended negative consequences on the environment of production and consumption processes (Genovese et al., 2017). Therefore, supplier selection is also one of the most important steps in achieving a sustainable supply chain. In supply chain studies, supplier selection has been mostly considered in a traditional environment, regardless of sustainability factors (Kuo et al., 2010). Sustainable Supply Chain Management (SSCM) provides economic, social, and environmental requirements in the flow of materials and services between suppliers and customers. SSCM structure is considered as a prerequisite for sustainable success. Designing a sustainable supply chain management structure provides a competitive advantage for companies. In the meantime, supplier selection based on sustainability principles and factors plays an important role in advancing the goals of the sustainable supply chain (Büyüközkan, 2011). Sustainable development is a concept that has been introduced since 1987 by the global environment and development community. Today, sustainable development is a very important issue in the face of increased environmental degradation (global warming, ozone depletion, etc.) and human rights violations.

Brindley and Borrow (2014) in “Conforming Supply Chain Management with Green Marketing Needs: A Case Study" address the challenges that organizations face when conforming with sustainable procurement requirements and market needs, and changes in terms of supply chain management practices. Azadi et al. (2015) in “A New Fuzzy Data Envelopment Analysis Model to Assess the Efficiency and Effectiveness of Suppliers in the Field of Sustainable Supply Chain Management" provide a new fuzzy integrated model for choosing sustainable suppliers. Su et al. (2015) in “Improving Sustainable Supply Chain Management Using the Novel Hierarchical Grey-DEMATEL Approach” are focused on developing the SSCM hierarchy at the initial stage and a novel hierarchical grey-DEMATEL approach to solve the incomplete information and hierarchical structure to obtain the relationship between the main criteria and the specific supplier. Mota et al. (2015) carried out a study on the economic, environmental and social design and planning of the sustainable supply chain of the company for the production and distribution of batteries in Portugal. Further studies are still ongoing in this field (Al-Odeh and Smallwood, 2012; Cetinkaya et al., 2011, Erol et al., 2011).

Data Envelopment Analysis (DEA) is a method for measuring the relative efficiency of similar decision-making units (DMUs) with input and output indicators and it is one of the most effective methods for identifying the best efficiency frontiers (Charnes et al., 1987). Its flexibility in the selection of input and output weights and its self-evaluation nature has been criticized. The cross-efficiency evaluation method is an extension of the data envelopment analysis that can be used to identify the best performance of decision-making units and to rank them using the size of cross efficiency associated with all decision-making units (Sexton et al., 1986). The main objective of cross-evaluation is to use data envelopment analysis in the peer evaluation instead of self-evaluation. Cross-evaluation has two main advantages:

I. It offers a unique rating for decision-making units

II. It eliminates the unrealistic weight designs without the need for the weight limits derived from the application of the field of specialty (Anderson et al., 2002)

- In any case, as Doyle and Green (1994) point out, the lack of uniqueness of the probable weight of the optimal data envelopment analysis may reduce the usefulness of cross-efficiency. Particularly, the cross efficiency measure derived from the underlying models of data envelopment analysis is generally not unique and the performance (cross-efficiency) of a decision-making unit may be improved by worsening the performance of the rest of the units, depending on the optimal linear programming solutions being used. Sexton et al. (1986) and Doyle and Green (1994) proposed the use of secondary goals to resolve non-unique results. They provided formulas for aggressive and benevolent models. For example, in the case of benevolent model, the idea of obtaining optimal weights maximizes the efficiency of a given decision-making unit under evaluation and the mean efficiency of other decision-making units. In the case of an aggressive model, it searches for the weights that minimize the efficiency of other units. In addition, further studies are still ongoing in this field (Rodder and Reucher, 2011; Rodder and Reucher, 2012; Moeini et al., 2015).

2. SUSTAINABLE SUPPLY CHAIN

The emergence of a concept called "Sustainable Development" in the report of the United Nations Environment and Development Committee in 1987 opened a new chapter in the debate on development. Along with the expansion of globalization over the past two decades, sustainability is converted from a technical concept into a political and then commercial mainstream (Liu et al., 2012). Traditional supply chain management focuses on cost, time and quality; however, nowadays, it has been extended to integrate environmental and social dimensions (Bentahar and Benzidia, 2018). Sustainable Supply Chain Management and achievement to sustainability in the supply chain are one of the most important supplier selection decisions and supplier-related policies that address the issue of globalization and transcontinental outsourcing. Besides, attention to the sustainability issue in these decisions has increased the importance of this issue in the formulation of organizational strategies and survival in a competitive environment (Seuring and Muller, 2008). Sustainable supply chain management is rooted in sustainability and it involves an extensive approach to supply chain management. Sustainability in the supply chain means pushing the supply chain towards the social, economic, and environmental aspects and addressing the existing problems in the traditional supply chain.

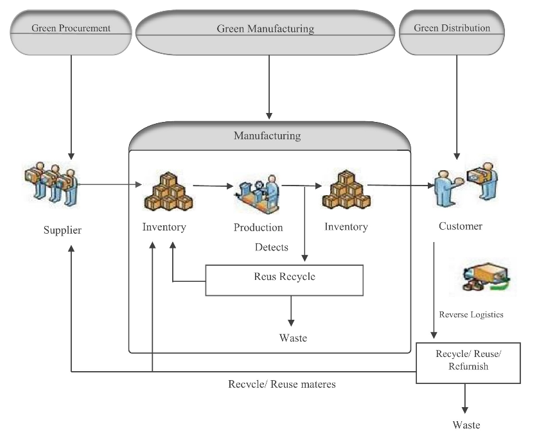

- Definition of sustainable supply chain: for years, the concept of the supply chain has existed and the supply chain can be defined as a system of organization, people, technology, activities, information and other resources in transferring a product or service from the supplier to the customer. However, the sustainable supply chain can be defined as a system of lifelong integrated business activities that creates the value-added for the stakeholders and improve people's well-being. In addition, the most accepted definition for sustainable supply chain management is as follows: supply chain management is the process of attention to environmental, economic, and social issues to increase the long-term economic goals of companies and their supply chain (Al-Odeh and Smallwood, 2012). The overall target framework for SSCM is shown in Figure 1 below. This Figure is a stable supply chain that is very similar to the regular supply chain with the difference that the reverse logistical activities, recycling, re-use and re-production are included in the regular supply chain (Hussain, 2011).

Figure 1. Sustainable Supply Chain Framework (Adapted from Hussain, 2011)

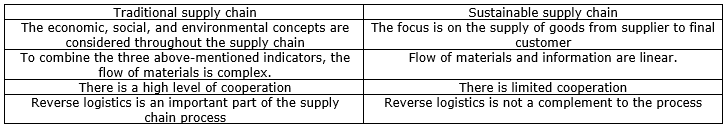

Based on what has been discussed so far, it is clear that the supply chain and sustainability are two different but very close and combined concepts. Table 1 shows the key differences between the sustainable and the traditional supply chains.

Table 1. The key differences between the sustainable chain and traditional supply chains

2.1 Cross efficiency in DEA

Data Envelopment Analysis (DEA) is a method for measuring the relative efficiency of decision-making units with several input and output indicators (Charnes et al., 1978). These decision-making units can be branches of the bank, non-profit institutions, factories, etc. (Liang et al., 2008). Usually, the flexibility of data envelopment analysis has been criticized in the selection of input and output weights and its self-evaluation nature (Bazrkar et al., 2017). Cross-efficiency evaluation is a useful approach to ranking decision making units (DMUs) in data envelopment analysis (DEA) (Liu, 2018). The cross efficiency evaluation method is the extension of the data envelopment analysis method, which can be used to identify the best performance of decision-making units and their ranking using cross-efficiency measures that are relevant to all decision-making units (Sexton et al., 1986).

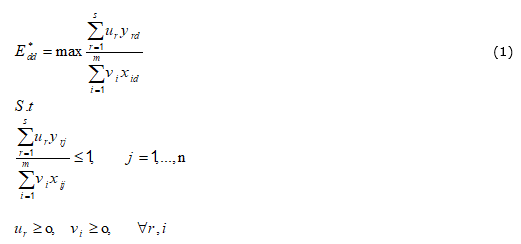

Suppose that there are n DMUs that generate s output by consuming m input. Also, the input i and the output r in DMUj are presented as xij and yrj. Charnes et al. (1978) presented the following CCR model for assessing the efficiency of DMUj.

The optimum value of the model (1) is smaller or equal to 1. DMUd is efficient if the optimal value of the above model is 1, otherwise, the unit is inefficient. Suppose that (ud,vd) are the optimal weights for DMUd using the CRR model. In this case, the cross efficiency of DMUd will be calculated according to the optimal DMUd weights.

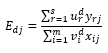

And the cross efficiency index of each unit is obtained using the following equation:

2.2 Secondary Objectives in Data Envelopment Analysis

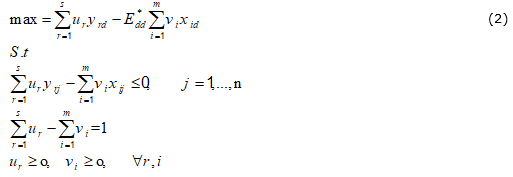

Like the CCR model in DEA, the model (1) also has multiple optimal results. The optimal multiple solution of model (1) results in different cross efficiency matrices. To solve this problem and obtain a unique cross efficiency matrix, here is a secondary objective model.

Consider the following model.

- Here, E*dd is the efficiency achieved using Model 1. Model 2 is a linear model and it can be shown that the optimal value of the model 2 is equal to zero. In fact, the calculated E*dd in the two models is the same (Moeini et al. 2015). Now, considering this model, a secondary objective model is proposed for the cross efficiency.

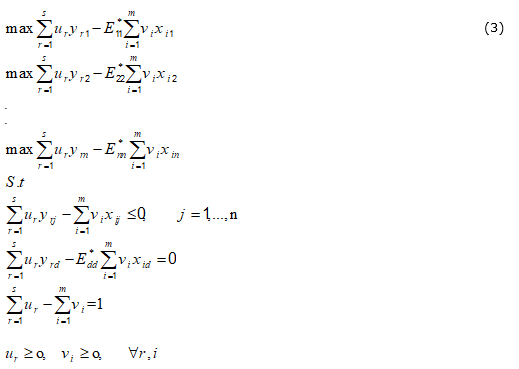

The secondary objective model presented here is based on maintaining the value of the decision-making unit's efficiency, i.e. DMUd and the maximization of the performance of other units simultaneously. In fact, the goal is to maximize the efficiency of n-1 decision-making units at the same time. To do this, a multi-objective model with n-1 objective function is used; objective function corresponds to the efficiency of a decision unit. Therefore, the secondary objective model will be expressed as follows:

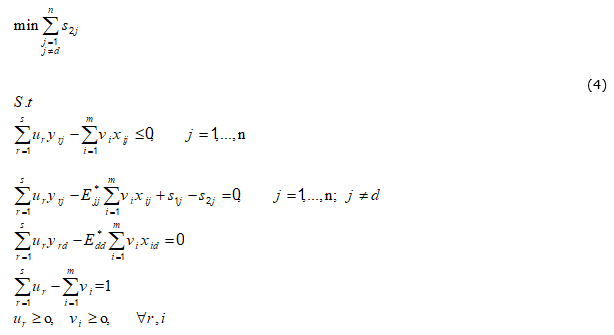

The above model is a multi-objective problem (Ehrgott, 2000). The purpose of this model is to maintain efficiency and maximize the performance of other DMUs simultaneously. In fact, the model above is a secondary objective model with a benevolent approach. The second constraint in model (2) has been added to the model to maintain the efficiency value of DMUd. In the above model, it is possible to use maximization instead of the minimization. This type of model will be an aggressive target, because in this case, the model seeks to minimize the efficiency of other decision-making units. In multi-objective problems, there are many methods for solving model (3). In all methods, the purpose of converting a multi-objective problem into a single-objective model is to solve it using mathematical programming methods (Ehrgott, 2000). Here, the goal programming method is used for solving a multi-objective model. In fact, multi-objective model 3 is converted as follows:

Here, the zero goal, which is the efficiency of the decision-making units, is considered that (j=1,...,n; j≠d)S2j,S2j are the positive and negative deviant variables.

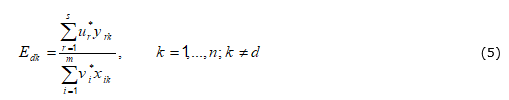

Now, if (v,u) is the optimal answer of model 3, then the cross efficiency of DMUd with respect to the optimal weights DMUd is:

Given the obtained values, the cross-efficiency matrix is calculated and the cross efficiency index of all DMUs can be calculated as follows:

3. METHOD

The present research is applied in terms of purpose and description based on a method. In this research, in the first step, a preliminary screening of the identified criteria is carried out. In this step, the criteria are identified according to the experts' opinion according to the statistical population of the study (Iranian automotive industry) and the statistical sample (Iran Khodro Co.). Localization at this stage is merely screening and, determining the degree of relevance of the factors in the framework is based on the environment, the conditions of the country, of the automotive industry, and Iran Khodro Co. Sampling at this stage is selective and based on the degree of expertise index. The localization of the criteria is done using structured interviews with 15 experts. Then, according to the identified criteria and statistical population of the study, the data on the final criteria is collected using a questionnaire. Finally, the evaluation and ranking of suppliers in sustainable supply chain of the automotive industry in Iran is done by cross-efficiency model presented in this paper. It should be noted that, due to the large number of active suppliers in the Iranian automotive industry, 12 major suppliers of Iran Khodro Company were selected as surveyed companies (Suppliers) according to the experts in the Supply Chain Management sector.

4. RESULTS

The evolution of supply chain management (SCM) over the last half century can be described through an increase in integration and information sharing (Muñuzuri et al., 2016).

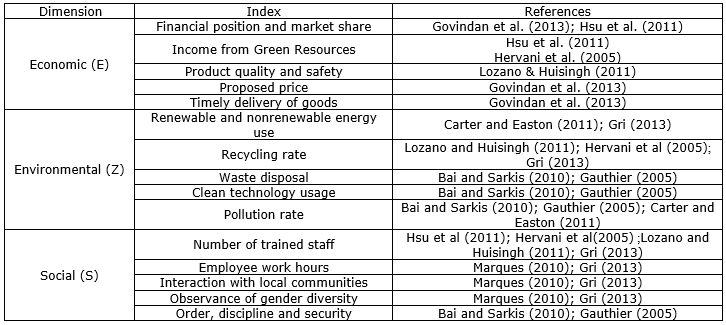

First, according to the literature review, most of the existing sustainability models have considered three environmental, economic and social dimensions as the main dimensions of sustainability. As a result, these three dimensions are considered as the main dimensions in this research. Table 2 summarizes the measures and sources.

Table 2. Identified criteria and their sources

Then, after interviewing experts in the field of sustainable supply chain in the automotive industry of Iran and the experts of Iran Khodro Co., the following criteria in the present study are used as the final criteria for evaluating the sustainable supply chain performance of the Iran Khodro Co., according to the experts:

- Income from green resources (output 1)

- Proposed price (input 1)

- Pollution rate (input 2)

- Waste disposal (input 3)

- Employee work hours (input 4)

- Recycling rate (output 2)

- Number of trained staff (input 5)

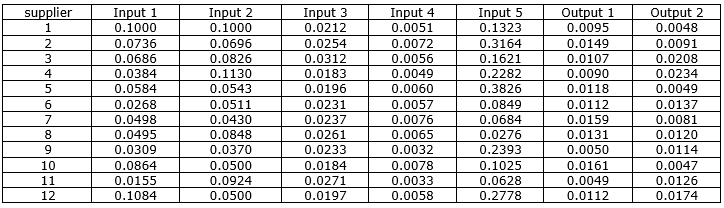

Information about inputs and outputs is given in Table 3.

Table 3. Normal data related to input and output indices of Iran Khodro Suppliers

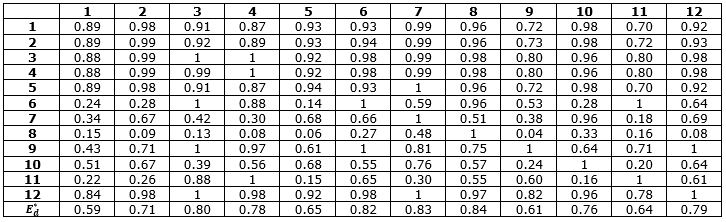

In this section, the model presented in this paper is used to rank the suppliers of the sustainable supply chain of the automotive industry. First, the model (1) will be solved and E*dd (d=1, ..., n) values are calculated. In the next step, using these values, the model (4) is solved and, according to (5), the cross-efficiency matrix will be formed as follows.

Table 4. Cross- efficiency matrix for assessing supply chain suppliers of Iran Khodro Co.

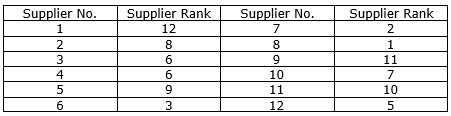

In addition, in the last row of the above cross-efficiency matrix, the cross-efficiency index for suppliers is calculated according to equation (6). These values are the basis for ranking suppliers. It is important to note that the values on the main matrix diameter are the values of CCR efficiency for suppliers. Nine out of 12 values are equal to 1, which means that 12 out of 9 suppliers are efficient suppliers. Therefore, the CCR model cannot provide a unique ranking of suppliers. However, if the suppliers are ranked using cross efficiency index E*d, a non-nodal ranking of suppliers is provided according to the last row of table 4 that these results are given in Table 5.

Table 5. Ranking of Iran Khodro Co. suppliers according to the results of cross-efficiency model

According to the results of Table 5, supplier No. 8 will be introduced as the most efficient supplier in the stable supply chain of Iran Khodro Co. This provider is recognized as an effective model and reference model, according to the Data Envelopment Analysis model. In addition, other suppliers can serve as a model for achieving more efficiency and moving towards sustainable development and contributing to the Green supply chain formation and to achieve sustainable development.

The results of this study showed that the cross efficiency model in data envelopment analysis is a very practical model for measuring the performance of supply chain performance. The results of this study are based on the results of the following studies: Yu et al. (2010), Dotoli et al.(2015) and Simsek and Tüysüz (2018), It matches.

5. CONCLUSION

Based on the discussions and results of this research, the study made an effort to find a suitable model for evaluating the performance and ranking of sustainable supply chain suppliers in the automotive industry of Iran for the population and 12 major suppliers of Iran Khodro Co. Accordingly, a cross efficiency model in data envelopment analysis was provided and used to rank the sustainable supply chain in the automotive industry in Iran. The results showed that, according to the criteria of the triple profit model (including 3 dimensions and 7 criteria), supplier No. 8 was identified as the most efficient decision maker unit (DMU) among 12 suppliers of Iran Khodro Company. Consequently, the cross efficiency model’s feature was providing a non-nodal ranking for suppliers, which cannot be done by the traditional data envelopment models. In this paper, the content presented for DEA models was assumed as a constant return to scale. However, it can be easily extended to variable return to scale. On the other hand, the model presented in this paper can be used for other applications in different domains, each of which can be considered in future works.

REFERENCES

Al-Odeh, M.; Smallwood, J. (2012). "Sustainable Supply Chain Management: Literature Review, Trends, and Framework", IJCEM International Journal of Computational Engineering & Management, Vol. 15, No. 1, pp. 85-90.

Anderson, T. R.; Hollingsworth, K. B.; Inman, L. B. (2002), “The fixed weighting nature of a cross-evaluation model”, Journal of Productivity Analysis, Vol. 17, No. 3, pp. 249–255. https://doi.org/10.1023/A:1015012121760.

Azadi, M.; Farzipoor Saen, R.; Jafarian Jelodar, M.; Mirhedayatian, S. M. (2015.), “A new fuzzy DEA model for evaluation of efficiency and effectiveness of suppliers in sustainable supply chain management context”, Computers & Operations Research, Vol. 54, pp. 247-285. https://doi.org/10.1016/j.cor.2014.03.002.

Bai, C.; Sarkis, J. (2010), "Integrating sustainability in to supplier selection with grey system and rough set methodologies". Int. J. Production Economics, Vol. 124, No. 1, pp. 252-264. https://doi.org/10.1016/j.ijpe.2009.11.023.

Bazrkar, A.; Iranzadeh, S.; Feghhi Farahmand, N. (2017), “Total quality model for aligning organization strategy, improving performance, and improving customer satisfaction by using an approach based on combination of balanced scorecard and lean six sigma”, Cogent Business & Management, Vol. 4, No. 1, 1390818. https://doi.org/10.1080/23311975.2017.1390818.

Bentahar, O.; Benzidia, S. (2018), ”Sustainable supply chain management: Trends and challenges”, Transportation Research Part E: Logistics and Transportation Review, Vol. 119, pp. 202-204. https://doi.org/10.1016/j.tre.2018.05.005.

Brindley, C.; Ox Borrow (2014), “Aligning the sustainable supply chain to green marketing needs: a case study”, Industrial Marketing Management, Vol. 43, No. 1, pp. 45–55. https://doi.org/10.1016/j.indmarman.2013.08.003.

Büyüközkan, G.; Berkol, Ç. (2011), "Designing a sustainable supply chain using an integrated analytic network process and goal programming approach in quality function deployment", Expert Systems with Applications, Vol. 38, No. 11, 13731-13748. https://doi.org/10.1016/j.eswa.2011.04.171.

Camioto, F.; Mariano, E.; Rebelatto, D. (2017), Sustainability improvement opportunities in Brazilian sectors: analysis of DEA slacks. Brazilian Journal of Operations & Production Management, Vol. 14, No. 3, pp. 363-370. https://doi.org/https://doi.org/10.14488/BJOPM.2017.v14.n3.a9.

Carter, C. R.; Easton, E. (2011) "Sustainable supply chain management: evolution and future directions", International Journal of Physical Distribution & Logistics Management, Vol. 41 Issue: 1, pp.46-62, https://doi.org/10.1108/09600031111101420.

Cetinkaya, B.; Cuthbertson, R.; Ewer, G.; klaasWissing, T.; Piotrowicz, W.; Tyssen, C. (2011), "Sustainable Supply Chain Management: Practical Ideas for Moving towards Best Practice", Springer-verlag Berlin Heidelberg.

Charnes, A.; Cooper, W. W.; Rhodes, E. (1978), "Measuring the efficiency of the decision making unit", European journal of operation Research, Vol. 2, No. 6, pp. 429-444. https://doi.org/10.1016/0377-2217(78)90138-8.

Dotoli, M.; Epicoco, N.; Falagario, M.; Sciancalepore, F. (2015), A cross-efficiency fuzzy Data Envelopment Analysis technique for performance evaluation of Decision Making Units under uncertainty q. Computers & Industrial Engineering, Vol. 79, pp. 103–114. https://doi.org/10.1016/j.cie.2014.10.026.

Doyle, J.; Green, R. (1994), “Efficiency and cross efficiency in DEA: Derivations, meanings and the uses”. Journal of the Operational Research Society, Vol. 45, No. 45, pp. 567 578. https://doi.org/10.2307/2584392.

Ehrgott, M. (2000). Multi criteria Optimization, volume 491 of Lecture Notes in Economics and Mathematical Systems. Springer-Verlag, Berlin. https://doi.org/10.1007/978-3-662-22199-0.

Erol, I.; Sencer, S.; Sari, R. (2011). "A new fuzzy multi criteria framework for measuring sustainability performance of a supply chain". Ecological Economics, Vol. 70, No. 6, pp. 1088–1100. https://doi.org/10.1016/j.ecolecon.2011.01.001.

Gauthier, C. (2005). "Measuring Corporate Social and Environmental Performance: The Extended Life-Cycle Assessment". Journal of Business Ethics, Vol 59, No. 1-2, pp. 199-206. https://doi.org/10.1007/s10551-005-3416-x.

Genovese, A.; Acquaye, A. A.; Figueroa, A.; LennyKoh, S. C.(2017). “Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications”. Omega, Vol. 66, Part B, pp. 344-357, https://doi.org/10.1016/j.omega.2015.05.015.

Govindan, K.; Khodaverdi, R.; Jafarian, A. (2013). "A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach". Journal of Cleaner Production, Vol. 47, pp. 345-354. https://doi.org/10.1016/j.jclepro.2012.04.014.

Gri (2013). “Sustainability reporting guidelines”. Available at: http://www.globalreporting.org Reports Database.

Hervani, A.; Helms, M.; Saikis, J. (2005). "Performance measurement for green supply chain management". Benchmarking: An International Journal, Vol. 12, No. 4, pp. 12, 330-353. https://doi.org/10.1108/14635770510609015.

Hsu, C.-W.; Hu, A. H.; Chiou, C.-Y.; Chen, T.-C. (2011). Using the FDM and ANP to construct a sustainability balanced scorecard for the semiconductor industry. Expert Systems with Applications, Vol. 38, No. 10, pp. 12891-12899. http://dx.doi. org/10.1016/j.eswa.2011.04.082

Hussain, M. (2011). Modeling the Enablers and Alternatives for Sustainable Supply Chain Management. Concordia University, A Thesis for the Degree Master of Applied Science (Quality Systems Engineering), Department of Concordia Institute for Information Systems Engineering.

Kuo, R.; Wang, Y. C.; Tien, F. C. (2010). "Integration of artificial neural network and MADA methods for green supplier selection". Journal of Cleaner Production, Vol. 18, No.12, pp. 1161-1170. https://doi.org/10.1016/j.jclepro.2010.03.020.

Liang, L.; Wu, J.; Cook, W.; Zhu, J. (2008), Alternative secondary goals in DEA cross efficiency evaluation, International Journal of Production Economics, Vol. 113, No. 2, pp. 1025–1030.

Liu, S. (2018). ”A DEA ranking method based on cross-efficiency intervals and signal-to-noise ratio”, Vol. 261, No. 1-2, pp. 207–232. https://doi.org/10.1007/s10479-017-2562-8

Liu, S.; Kasturiratne, D.; Mozier, J. (2012). “A hub-and-spoke model for multi-dimensional integration of green marketing and sustainable supply chain management”. Industrial Marketing Management, Vol. 41, No. 4, pp. 581-588, https://doi.org/10.1016/j.indmarman.2012.04.005.

Lozano, R.; Huisingh, D. (2011). “Inter-linking issues and dimensions in sustainability reporting”. Journal of Cleaner Production, Vol. 19, No. 2-3, pp. 99-107. https://doi.org/10.1016/j.jclepro.2010.01.004.

Marques, J. (2010), ”Spiritual Considerations for Managers: What Matters Most to Workforce Members in Challenging Times”, Journal of Business Ethics, Vol. 97, No. 3, pp. 381–390. https://doi.org/10.1007/s10551-010-0514-1.

Moeini, M.; Karimi, B.; Khorram, E. (2015). “A Cross-Efficiency Approach for Evaluating Decision Making Units in Presence of Undesirable Outputs”. In Modelling, Computation and Optimization in Information Systems and Management Sciences (pp. 487-498). Springer International Publishing. https://doi.org/10.1007/978-3-319-18167-7_42.

Mota, B.; Gomes, M.; Carvalho, A.; Barbosa-Povoa, P. (2015),” Towards supply chain sustainability: economic, environmental and social design and planning”, Journal of Cleaner Production, Vol.105, pp.14-27. https://doi.org/10.1016/j.jclepro.2014.07.052.

Muñuzuri, J.; Onieva, L.; Escudero, A.; Cortés, P. (2016). Impacts of a tracking and tracing system for containers in a port-based supply chain. Brazilian Journal of Operations & Production Management, Vol. 13, No. 3, pp. 352-359. https://doi.org/https://doi.org/10.14488/BJOPM.2016.v13.n3.a12

Rodder, W.; Reucher, E. (2011), “A consensual peer-based DEA-model with optimized cross-efficiencies: input allocation instead of radial reduction”, European Journal of Operational Research, Vol. 212, No. 1, pp. 148–154. https://doi.org/10.1016/j.ejor.2011.01.035

Rodder, W.; Reucher, E. (2012), “Advanced x-efficiencies for CCR- and bcc-models: towards peer-based DEA controlling”, European Journal of Operational Research, Vol. 219, No. 2, pp. 467–476. https://doi.org/10.1016/j.ejor.2011.12.024.

Seuring, S.; Muller, M. (2008). “From a literature review to a conceptual framework for sustainable supply chain management”. Journal of Cleaner Production, Vol. 16, No. 15, pp. 1699-1710. https://doi.org/10.1016/j.jclepro.2008.04.020.

Sexton, T. R.; Silkman, R. H.; Hogan, A. J. (1986). “Data envelopment analysis: Critique and extensions”. In: Silkman, R. H. (Ed.), Measuring Efficiency: An Assessment of Data Envelopment Analysis, Vol. 32. Jossey-Bass, San Francisco, pp. 73–105.

Simsek, B.; Tüysüz, F. (2018), "An application of network data envelopment analysis with fuzzy data for the performance evaluation in cargo sector", Journal of Enterprise Information Management, Vol. 31, No. 4, pp. 492-509. https://doi.org/10.1108/JEIM-01-2017-0026

Su, C.; Horng, D.; Tseng, M. et al. (2016). “Improving sustainable supply chain management using a novel hierarchical grey-DEMATEL approach”. Journal of Cleaner Production.Vol.134, Phar.B., 469-481. https://doi.org/10.1016/j.jclepro.2015.05.080.

Yu, M. M.; Ting, S. C.; Chen, M. C. (2010).”Evaluating the cross-efficiency of information sharing in supply chains”, Expert Systems with Applications, Vol. 37, No. 4, pp. 2891-2897. https://doi.org/10.1016/j.eswa.2009.09.048.

Received: 25 Oct 2018

Approved: 24 Nov 2018

DOI: 10.14488/BJOPM.2019.v16.n1.a4

How to cite: Tabatabaei, M. H.; Bazrkar, A. (2019), “Providing a Model for Ranking Suppliers in the Sustainable Supply Chain Using Cross Efficiency Method in Data Envelopment Analysis”, Brazilian Journal of Operations & Production Management, Vol. 16, No. 1, pp. 43-52, available from: https://bjopm.emnuvens.com.br/bjopm/article/view/593 (access year month day).