Obtaining FMEA’s indices for occupational safety in civil construction: a theoretical contribution

Andre Luis De Oliveira Cavaignac

andreluiscavaignac@gmail.com

Ceuma University – UNICEUMA, São Luís, Maranhão, Brazil

Jhelison Gabriel Lima Uchoa

jhelisong@hotmail.com

Ceuma University – UNICEUMA, São Luís, Maranhão, Brazil

ABSTRACT

Highlights: 1- Severity, occurrence and detection indices were obtained for specific use in construction safety; 2- Important theoretical contribution to the use of FMEA in safety of construction work; 3- Obtaining the S, O and D indices better suited to civil construction will encourage the use of FMEA in the area; 4- A quick reference table of S, O and D indexes was proposed for use by occupational safety professionals; 5- The quick reference table will allow the RPNs of the fault modes to be safely compared between different situations and different applicators.

Goal: The achievement of FMEA indices better adapted to the area of occupational safety in construction. From a quick reference table, the use of the FMEA will be facilitated by professionals in the area.

Design / Methodology / Approach: For the elaboration of this work were carried out researches in the literature available in scientific journals on the subject. To obtain the severity tables, the conversion of concepts of maintenance and reliability to concepts of accident severity was performed. For the occurrence table the Ford Handbook model was used (FORD, 2011), and as the database of accident statistics the most up-to-date social security yearbook was used (FAZENDA, 2016). For the detection table, a detection index model was proposed that was discussed based on commonly used risk management procedures and tools.

Results: Individual tables were obtained for each FMEA index. The indices were adapted to the reality of the application of FMEA in work safety in construction. From the individual tables, a quick reference table containing the three FMEA indices related to the qualitative scale of each was obtained.

Limitations of the investigation: The study limits itself to adapting the FMEA indices for work safety in construction. This study may serve as a basis for future studies on obtaining the FMEA indexes for work safety applied in other areas of activities, requiring adequate scientific sources. Regarding the validation of the indices, it is noticeable the difficulty of comparing these indices proposed in this work with indices applied subjectively and without scientific reference, relying only on the skill and previous experience of the applicator. However, it is reasonable to say that the FMEAS applied with the indices obtained in this work will have a better accuracy in representing the reality, regardless of the applicator's ability.

Practical implications: Reduce the difficulties in choosing the S, O and D indices for the application of FMEA in construction safety, reduce the inaccuracy in obtaining the risk priority number for failure modes and diffuse the use of FMEA for risk analysis and prevention occupations in construction are the main theoretical implications of this work.

Originality / Value: there are studies in the literature on the application of FMEA in various areas - maintenance and product development, for example - but there is very little research on the application of FMEA in occupational safety. In addition, FMEA application studies cite the difficulty of choosing the S, O and D indices, but there is an absence of studies seeking solutions to this imprecision. In this sense, this work seeks to contribute to a choice of the FMEA indexes, which is easier and more efficient due to the better adaptation of the same to the occupational safety area in civil construction.

1 INTRODUCTION

With the growing interest of construction companies in obtaining certifications, such as ISO 9001, ISO 14001 and OHSAS 18001, there is a need to improve risk analysis and management tools (Zeng et al., 2010). Civil construction is an important element for the Brazilian economy and it is essential as an instrument of public policies, since it guarantees the generation of employment and income (Mello and Amorim, 2009). The construction industry is comprised of 94% of micro and small enterprises, with low technical development and high labor turnover, leading to a low specialization in their activities (Teixeira and Carvalho, 2005). In this way, the construction industry is a fertile field for high rates of industrial accidents. In the year 2016 there were 34,786 accidents involving the removal of employees enrolled in construction activities. From the total of these accidents, the impact caused by the fall of materials and the fall of employees, among different levels, stand out as causes (Fazenda, 2016).

Working at heightsis awidely performed activity within civil construction worldwide and itoffers several risks, both for those who execute it and for who is exposed to possible falls of materials. In the North American civil construction, falls from height have the highest rate of fatalities within works, with approximately 35% of deaths recorded and reports of 49 fatalities due to falling objects (Mroszczyk, 2015).

Workplace accidents are responsible for major losses in the industry. As cost-generating instruments resulting from work-related accidents, the causes of separation within the process and the cost generated, with salary payments to workers on medical leave, first aid expenses and recovery of the injured worker are highlighted; loss of equipment, materials and repair engineering costs; and losses with downtime and compensatory overtime (Costaet al., 2009). In a total of 2,857 work accidents registered in Bahia's social security system in 2000, 18% of accidents related to the construction industry were detected, with estimated costs of R$ 8.5 million (Santana et al., 2006). Because of this, it is essential to assess the risks associated with the tasks in order to avoid accidents or failures, in order to guarantee the quality, deadlines, costs and safety of all that is related to the work. Risk assessment should be present at all stages of construction or reform, both in prevention within the project phase and its implementation (Cruz, 2012).

According to Stamatis(2003), the FMEA, or failure mode and effects analysis is one of the methods of fault evaluation, which correlates its causes and effects, also punctuating the means of its detection, prevention and mitigation of effects. Developed as a military procedure by the US military in the post-war 1940s (Pentti and Atte, 2002) has been widely used in engineering industries and is now used in other areas such as food safety (Scipioni et al., 2002), management procedures (Milazzoet al., 2009; Rhee and Ishii, 2003) and critical medicine and trauma (Duwe and Hansen-Flaschen, 2005; Day et al., 2006; Derosier et al., 2005).The use of the FMEA for the area of occupational safety is still not widespread, requiring scientific studies on the subject.

The FMEA allows a hierarchy of risks, prioritizing failure modes according to a coefficient called a risk priority number, or RPN. This number is a result of the multiplication of three independent indices - severity (S), occurrence (O) and detection (D) - and varies from 1 to 10, the worse its reality.

According to Mcdermott et al.(2009), severity is the classification that indicates the severity of a possible consequence in the potential mode of a fault. In maintenance there is a direct connection between the effects of the failure in the system or process and the severity index that will be assigned. If the effects are critical to the proper functioning of the process the severity will be high and if the effects are not critical the severity will be low.

The occurrence in FMEA is the estimation of the frequency or probability of failure mode occurring. The best method to determine its value is through the use of real data of the process; however, in the case where there are data for evaluation, qualitative scales can be assigned (Mcdermott et al., 2009).For the maintenance area there are tables of quite consolidated indices of occurrence (Ford, 2011; Mcdermott et al., 2009; Stamatis, 2003); however, the occupational safety area does not have studies correlating the occurrence indexes with actual data. Thus, a certain difficulty is generated to the FMEA applicators in the choice of indices in a qualitative way (Laurentiet al., 2012).

Detection is the difficulty of causing the fault to be detected before the failure mode occurs. For the maintenance area, the probability of detection is conceptualized between very low and very high, relating the concepts from 1 to 10 with the probability of detection (Stamatis, 2003).The absence of failure detection histories is a complicating factor for the correct use of this index and, in many situations, obtaining the FMEA detection index is based on the experience that is reported by the collaborators making the analysis imprecise (Posso and Estorilio, 2009). Other factors that may influence are the nature of the failure, the checking procedures and the difficulty in technological detection procedures (Mcdermott et al., 2009). In occupational safety, the difficulty of detecting the failure mode is great due to the lack of control procedures that generate statistical data for this, requiring studies on the subject.

The use of FMEA has a wide range of possible improvements. The studies on the application of FMEA frequently enumerate as main difficulties the imprecision of the Risk Priority Number (RPN) obtained to define the risk, with the same RPN representing different situations; the need for a large amount of time to apply a judicious FMEA; the dependence of the experience of the team members for the tool application (Laurentiet al., 2012). The difficulty in estimating the values for the S, O and D indices is also highlighted by Laurenti et al.,(2012). This difficulty, in particular, is relevant to the area of occupational safety, which is absent from using the FMEA, limiting itself to using purely qualitative risk management tools.

The method of failure analysis and its effects by the FMEA may be applied within the works in conjunction with the knowledge of the current Regulatory Standards (NSs) to mitigate potential risks. Because of this, the present work seeks to contribute to the area of risk management and analysis in occupational safety by proposing a methodology to obtain the indexes that compose the RPN to facilitate the use of FMEA in the analysis and prevention of accident risks. In this way, this work seeks to contribute theoretically to the use of FMEA in occupational safety in the construction industry through a better adjustment of the concepts S, O and D for this use.

2 METHODOLOGY

For the elaboration of this work research was carried out in the literature available in scientific journals on the subject. To obtain the severity tables, the conversion of concepts of maintenance and reliability to concepts of accident severity was performed. For the occurrence table, the Ford Handbook model was used (Ford, 2011) and, as the database of accident statistics, the most up-to-date social security yearbook was used (Fazenda, 2016). For the detection table, a detection index model that was discussed based on commonly used risk management procedures and tools was proposed.

3 S, O AND D TABLES FOR OCCUPATIONAL SAFETY IN CONSTRUCTION

In view of the difficulties reported in the scientific literature, the best adaptation of the S, O and D indices for specific application in construction safety is necessary. Next, a discussion will be made on the S, O, and D indices, exposing the methods used to obtain each one.

3.1 Obtaining the severity index (S)

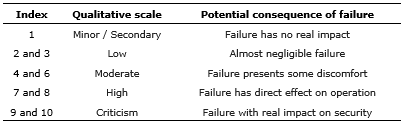

This classification is done using a numerical scale from 1 to 10, where the classification 1 corresponds to a zero or imperceptible severity and the classification 10 is the worst possible consequence for the failure mode analyzed. The indices that Stamatis(2003) propose are shown in table 1.

Table 1. Scale of severity for processes or services.

Source: Stamatis, 2003 (Adapted)

In table 1, the index with smaller scale represents a minor or secondary fault with no real impact as consequence and the highest index is a critical fault with a real impact on safety. This characterization of Stamatis (2003) can be translated for occupational safety.

Most construction accidents are deadly; therefore, severities must consider aspects beyond economic damage (Song et al., 2007). Based on studies by the Korea Occupational Safety and Health Agency (KOSHA), Song et al.(2007) presents a numerical model from 1 to 6, where it considers the time of medical treatment of the consequences of the failures to define the severity. The employee's absence time with the company, together with a qualitative description of the effects of the accidents caused by the faults can be used to define the severity (Patricio et al.,2013). Holt (2008) presents a scoring system, from 1 to 15, of the consequences of risks in construction, where first aid is considered as low severity and multiple fatalities are regarded as critical failures. Its index also assigns a score to the number of workers exposed to risk.

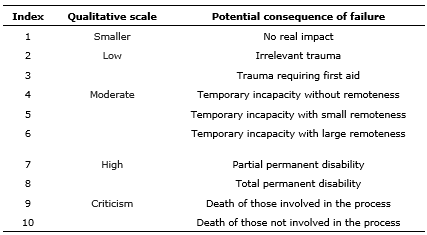

These indices can be adapted to the Stamatis (2003) index presented previously, assigning a scale of 1 to 10 and correlating the qualitative scales with each other. Table 2 presents the new index proposed by the adaptation.

Table 2. Adapted model of the severity scale

Source: Adapted from Stamatis, 2003; Patricio et al., 2013; Holt, 2008

Failure of no real impact is one in which there are no physical sequelae on employees, thus not causing loss of working time. Irrelevant traumas are those where failure can cause slight physical sequelae, but still without causing loss of working time. The trauma requiring first aid differs from irrelevant trauma because it causes temporary disruption of activity due to the need for first aid.

Temporary disabilities are characterized as partial or absolute, the first occurring when the worker is still able to perform 50% of his abilities, even with difficulties, and the second happens when the employee is totally unable to perform his professional activities (Durão et al., 2012).In this sense, three types of temporary incapacities are proposed: without remoteness, with small remoteness, and with large remoteness.

Temporary incapacity without remoteness is the one in which the collaborator affected by an injury has to engage in another, simpler task until the incapacity is solved, as long as the injury does not require remoteness.

Temporary incapacity with small remoteness is the event in which the collaborator cannot be relocated to another function due to the severity of the trauma, requiring full remoteness for recovery, but not exceeding 15 days, thus excluding the necessity of social security.

Large remoteness, on the other side, is the period of more than fifteen days in which the collaborator needs social security for a complete recovery.

Permanent disability, called "permanent damage", is characterized by the loss of work capacity resulting from one or more dysfunctions or sequelae left in patients, which prevents them from performing any type of work (Durão et al., 2012). However, according to the social rehabilitation professional program, people with partial permanent disability can be relocated to work functions where they can adapt (Takahashi and Iguti, 2008). In this way, partial permanent disability is one in which employees have permanent sequelae; however, there is the possibility of continuing to perform other possible job functions to adapt. The total permanent disability is the one that the sequels of the accident do not allow the worker to be reinstated in any job function.

The worst severity indexes, 9 and 10, are intended for accidents involving deaths. In this severity range, there are 9 accidents that lead to the death of employees directly involved in the process. Accidents that cause the death of the employees who are not directly involved in the function, in addition to those who execute the process, due to their magnitude, obtain the maximum index in the proposed severity scale, 10.

3.2 Obtaining the occurrence index (O)

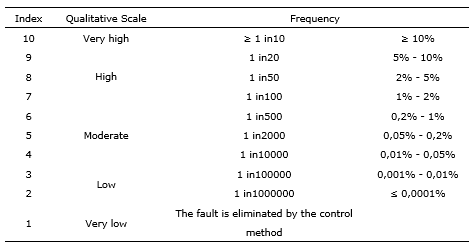

Table 3 shows the parameters for evaluating the occurrence criterion proposed by Ford(2011). It is possible to adjust the occurrence index presented by Ford(2011) through a statistical analysis of the values obtained from studies of work accidents in civil construction. Since the occurrence index model is based on the frequency of the occurrence of the fault, the number of accidents, delimited by the causes and divided by the number of active employees, will be used for the analysis. Thus, it is possible to determine the probability of the cause of the accident for each active worker.

Table 3. Evaluation criterion of the occurrence.

Source: FORD (2011). Adapted

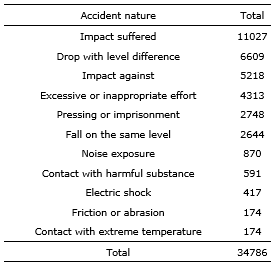

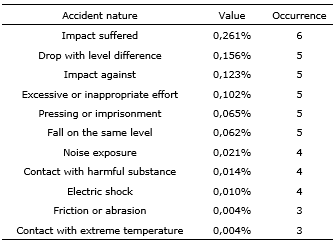

Guimarães et al.(2000) proposes in his study a statistical analysis of the distribution of accidents in civil construction according to their nature. Their results can be used to delimit the causes of accidents using the quantitative forms of the Social Security statistical forms for the year 2016, thus obtaining the relation of the accidents associated to their causes, as presented in table 4.

Table 4. Comparative values of accidents for the year 2016

Source: Interpolation between Fazenda (2016) and Guimarães et al.(2000)

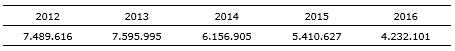

With these values, a new interpolation is then made with the statistics of taxpayers employed in the economic sector of construction in the year 2016, presented in table 5.

Table 5. Statistics of taxpayers employed in the civil construction sector.

Source: Fazenda (2016). (Adapted)

Thus, it is possible to determine the probability of occurrence of the cause of the failure for each employee hired in 2016. Applying this result in the generic index presented by Ford(2011), an estimate of the occurrence index of the causes of accidents in the civil construction sector is obtained.

Table 6. Percentage of the number of accidents by the number of taxpayers.

Fonte: Interpolation between Fazenda (2016), Ford (2011), and Guimarães et al.(2000)

These values, shown in Table 6, based on occupational safety, can then be used to determine the occurrence rates (O) for the application of FMEA in the different areas of construction. At this point it is valuable to point out that the information in table 6 can be updated annually, from the new edition of the social security yearbook. The synthesis of the method of updating the occurrence index (O) starts from the proportions obtained by Guimarães et al.(2000),applied in the total number of work-related accidents recorded in the social security system, annually disclosed by the body, comparing the number of accidents with the total number of inscribed in the economic activity of construction and converting the percentages obtained into occurrence indexes from the table proposed by Ford (2011).

3.3 Obtaining the detection index (D)

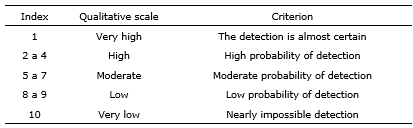

Detection is the probability that existing control measures detect the failure mode root before it is played. This detection can be done by repeated inspection activities, by checking procedures before using the element or by automated devices. It is represented by a numerical scale where the highest value represents a very low or no chance of failure detection and the lowest value represents an immediate detection. Table 7 shows the correlation between the difficulty of detection and the scale of the detection index.

Table 7. Detection index.

Source: Stamatis, 2003

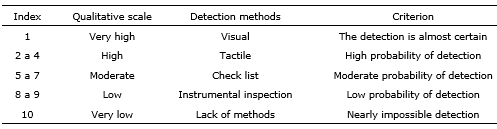

The use of qualitative scales in relation to the detection can be made from the check methods available in safety of the work. From empiric observations, some methods, as the visual inspection, were enumerated, detecting the existence or absence of safety devices, such as devices that prevent falls of people and materials in height (skirting boards, elevator pit guards, use of lanyards, etc.); manual or tactile routine inspection (checking the condition of paratrooper belts, placing of ladders, firmness in the scaffolding, etc.); procedural checklists, where several visual and tactile inspections are required in sequence prior to the execution of the task; and mechanical tests, such as loading tests on lifeline anchorages, for example; furthermore, if it is still not possible to detect the source of the fault, the detection difficulty index rises to 10. Thus, it is reasonable to correlate the safety inspection methods available with the qualitative scale proposed by Stamatis (2003). The correlation is shown in table 8.

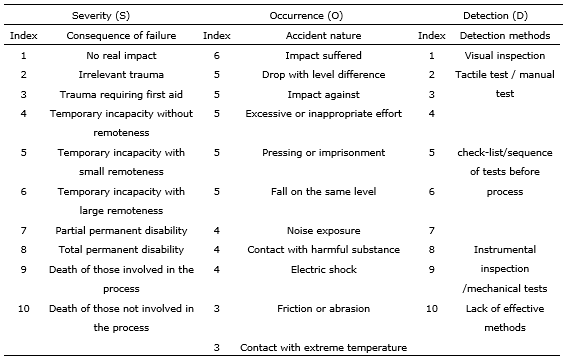

Table 8. Correlation of detection methods with the qualitative scale of Stamatis (2003) to obtain the detection index for FMEA.

Source: Stamatis, 2003. (Adapted)

It is noticed that it is difficult to determine detection indices, even in defined areas such as maintenance, due to the lack of records; therefore, one can expect even greater difficulty in a new application in the area of occupational safety. A deeper study of the detection index is necessary, especially in an opportunity where there is a history of inspection and detection records of possible causes of accidents.

3.4 Indices S, O and D, for occupational safety in civil construction

Table 9 shows a fast access correlation between the severity (S), occurrence (O) and detection (D) indices, with their qualitative concepts, usually found in occupational safety for civil construction. For the qualification of severity, the qualitative definition of severity proposed by Stamatis (2003) was expanded with definitions of Song et al.(2007), Patricio et al.(2013), Holt (2008), and Durão et al.(2012). Thus, each index has a correlation with the nature of severity, starting from an index 1, where there is no real impact, up to index 10, where there are deaths of people external to the process. For the occurrence qualification (O), for each nature of the occurrence, there is a correlation with the respective index based on the probability defined by Ford (2011) and adapted with the data of Fazenda (2016) and Guimarães et al. (2000). For the quantification of the detection indices (D), each index was correlated with the difficulty of adapted detection of Stamatis (2003), starting from an index 1, where the primary cause of the failure can be detected with simple visual inspections, up to an index 10 where it is assumed that there are no available techniques to ensure detection. Table 9 is proposed as a tool for quick reference to the professionals who elaborate, execute and research the topic of occupational safety, in order to reduce the difficulty of using the FMEA reported by Laurenti et al.(2012).

Table 9. Reference table of severity (S), occurrence (O) and detection (D) indexes, for the application of FMEA in analysis and risk prevention for occupational safety in construction

Source: the authors

It is worth to point out that, regarding the validation of the indices, it is noticeable the difficulty of comparing the indices proposed in this work with indices applied subjectively and without scientific reference, relying only on the skill and previous experience of the applicator. For that, this comparison requires a specific scientific methodology, demanding specific scientific work for this situation.

However, it is reasonable to say that the FMEAS applied with the indices obtained in this work will have a better accuracy in representing the reality, regardless of the applicator's ability. In this way, the contribution of this work is to offer a reference point so that the RPNs can be compared between FMEA applications at different times by different applicators, bringing to the tool a quantitative power that is not dependent on the applicator subjectivity, thus, nearing the reality of the FMEA in occupational safety of the FMEA in the areas of maintenance and reliability, for example.

4 CONCLUSIONS

This work sought to contribute to the area of risk analysis and management in occupational safety by obtaining indexes S, O, and D, best adapted for the use of FMEA in work safety, with emphasis on civil construction. The literature on the subject points out that the lack of clarity in the choice of S, O, and D indices generates difficulties in terms of the use of FMEA. In this sense, the creation of index tables S, O, and D, clearly and previously adapted for the use in work safety can be a mechanism that will promotes the diffusion of the use of FMEA in this area of knowledge. In this paper, it was attempted to construct a clear correlation between the S, O, and D indices with the reality of work safety in civil construction. Correlation tables of the S, O, and D indexes were obtained from the methodology described during the study. From the tables obtained, a quick reference table was constructed that includes the three indexes S, O, and D, related to their respective nature. Thus, this work sought to provide a fast and safe reference for professionals responsible for execution and research on the subject of work safety, with emphasis on construction.

REFERENCES

Costa, J. F.; Risicato, L. B.; Torres, C. A. (2009), "Metodologia Multicritério na Avaliação de Custos na Segurança do Trabalho", Sistemas & Gestão, Vol. 1, No. 2, pp. 104-115.

Cruz, P. M. (2012), Aplicação do "Failure Mode and Effect Analysis (FMEA)" na Demolição, Movimento de Terras e Execução de Estruturas em Edifícios, Dissertação (Mestrado em Engenharia Civil), Instituto Politécnico do Porto, Instituto Superior de Engenharia do Porto.

Day, S. R.; Dalto, J. R.; Fox, J. R.; Turpin, M. B. (2006), "Failure Mode and Effects Analysis as a Performance Improvement Tool in Trauma", Journal of Trauma Nursing, Vol. 13, No. 3, pp. 111-117.

Derosier, J.; Stalhandske, E.; Bagian, J. P.; Nudell, T. (2005), Using Health Care Failure Mode and Effect Analysis™: The VA National Center for Patient Safety’s Prospective Risk Analysis System, The Joint Commission Journal on Quality Improvement, Vol. 28, No. 5, p. 248-267. PMID: 12053459

Durão, C.; Pinto, R.; Nuno, D. (2012), "O papel do ortopedista nos acidentes de trabalho", Revista Portuguesa de Ortopedia e Traumatologia, Vol. 20, No. 3, pp. 295-302. Available from: http://www.scielo.mec.pt/scielo.php?script=sci_arttext&pid=S1646-21222012000300004 (access 21 jun. 2018)

Duwe, B. D. F. B.; Hansen-Flaschen, J. (2005), "Failure mode and effects analysis application to critical care medicine", Critical Care Clinics, Vol. 21, pp. 21-30.DOI: 10.1016/j.ccc.2004.07.005

Fazenda, M. D. (2016), Anuário estatístico da previdência social, Instituto Nacional do Seguro Social, Brasília. Available from: http://www.previdencia.gov.br/wp-content/uploads/2018/07/aeps2016.pdf (access 22 jun 2018)

Ford, M. C. (2011), Failure Mode and Effects Analysis: FMEA Handbook, 4.2 ed. Available from: https://fsp.portal.covisint.com/documents/106025/14555722/FMEA+Handbook+v4.2/4c14da5c-0842-4e60-a88b-75c18e143cf7?version=1.0 (access 21 jun. 2018)

Guimarães, L. B.; Costella, M. F.; Cremonini, R. A. (2000), Analysis of work accidents and professional diseases in rio grande do sul state construction industry, Proceedings of the IEA 2000/Human Factors and Ergonomics Society Annual Meeting. Available from: http://journals.sagepub.com/doi/pdf/10.1177/154193120004403334 (access 13 jul. 2018)

Holt, A. S. J. (2008), Principles of construction safety.John Wiley & Sons.

Laurenti, R.; Villari, B. D.; Rozenfeld, H. (2012), "Problemas e melhorias do método FMEA: uma revisão sistemática da literatura", P&D em Engenharia de Produção, Vol. 10, No. 1, pp. 59-70. Available from: https://www.revista-ped.unifei.edu.br/documentos/V10N01/06-1211-V10-N1-2012.pdf (access 23 jun 2018)

Mcdermott, R.; Mikulak, R. J.; Beauregard, M. (2009), The basics of FMEA. CRC Press, 2009.(2 ed.). CRC Press.

Mello, L. C.; Amorim, S. R. (2009), "O subsetor de edificações da construção civil no Brasil: uma análise comparativa em relação à União Europeia e aos Estados Unidos", Production Journal, Vol.19, pp. 388-399. DOI: 10.1590/S0103-65132009000200013.

Milazzo, M. F.; Ancione, G.; Lisi, R.; Vianello, C.; Maschio, G. (2009), "Risk management of terrorist attacks in the transport of hazardous materials using dynamic geo events", Journal of Loss Prevention in the Process Industries, Vol. 22, No. 5, pp. 625-633. DOI: 10.1016/j.jlp.2009.02.014

Mroszczyk, J. W. (2015), Improving Construction Safety: a Team Effort, Professional Safety, pp. 55-68. Available from: https://aeasseincludes.assp.org/professionalsafety/pastissues/060/06/F2Mros_0615.pdf (access 15 jun. 2018)

Patricio, R. P.; Catai. R. E.; Michaud. C. R.; Nagalli, A. (2013), "Model of risk management based in the FMEA technique–a case study in the construction of Gabions", Electron J Geotech Eng, Vol. 18, pp. 4183-4199. Available from: http://www.ejge.com/2013/Ppr2013.378mlr.pdf (access 13 jun. 2018).

Pentti, H.; Atte, H. (2002). Failure mode and effects analysis of software - based automation systems. STUK - Radiation and Nuclear Safety Authority, Helsinki. Available from: http://www.julkari.fi/bitstream/handle/10024/124480/stuk-yto-tr190.pdf?sequence=1 (access 28 jun. 2018)

Posso, R.; Estorilio, C. (2009), "Identificação dos Fatores de Influência na Aplicação do Método Failure Mode and Effect Analysis - FMEA de Processo: um estudo em produtos estampados", Produto & Produção,Vol. 10, No. 2, pp. 87-107. DOI: 10.22456/1983-8026.8997

Rhee, S. J.; Ishii, K. (2003), "Using cost based FMEA to enhance reliability and serviceability", Advanced Engineering Informatics, Vol. 17, No. 3-4, pp. 179-188. DOI: 10.1016/j.aei.2004.07.002

Santana, V. S.; Araújo-Filho, J. B.; Albuquerque-Oliveira, P. R.; Barbosa-Branco, A. (2006), "Acidentes de trabalho: custos previdenciários e dias de trabalho perdidos", Revista de Saúde Pública, Vol. 40, No. 6, pp. 1004-1012. DOI: 10.1590/S0034-89102006000700007.

Scipioni, A.; Saccarola, G.; A., C.; Arena, F. (2002), "FMEA methodology design, implementation and integration with HACCP system in a food company", Food Control, Vol. 13, No. 8, pp. 495-501. DOI: 10.1016/S0956-7135(02)00029-4

Song, J.W.; Yu, J. H.; Kim, C. D. (2007), Construction safety management using FMEA technique: Focusing on the cases of steel frame work. 23rd Annual ARCOM Conference, p. 3-5. Available from: http://www.arcom.ac.uk/-docs/proceedings/ar2007-0055-0063_Song_Yu_and_Kim.pdf (access 28 jun. 2018)

Stamatis, D. H. (2003), Failure Mode and Effect Analysis - FMEA from Theory to Execution (2nd ed.), Milwaukee, USA: ASQ Quality Press.

Takahashi, M. A.; Iguti, A. M. (2008), "As mudanças nas práticas de reabilitação profi ssional da Previdência Social no Brasil: modernização ou enfraquecimento da proteção social?", Caderno de Saúde Pública, Vol. 24, No. 11, pp. 2661-2670. DOI: 10.1590/S0102-311X2008001100021.

Teixeira, L. P.; Carvalho, F. M. (2005), "A construção civil como instrumento de desenvolvimento da economia brasileira", Revista Paranaense de Desenvolvimento, No. 109, pp. 09-26. DOI: 10.1590/S0102-311X2008001100021.

Zeng, S. X.; Tam, C. M.; Tam, V. W. (2010), "Integrating Safety, Environmental and Quality Risks for Project Management Using a FMEA Method", Inzinerine Ekonomika-Engineering Economics, Vol. 21, No. 1, pp. 44-52. Available from: http://inzeko.ktu.lt/index.php/EE/article/view/11645/6327 (access 3 jul. 2018)

Received: 17 Aug 2017

Approved: 01 Nov 2018

DOI: 10.14488/BJOPM.2018.v15.n4.a9

How to cite: Cavaignac, A. L. O.; Uchoa, J. G. L. (2018), “Obtaining FMEA’s indices for occupational safety in civil construction: a theoretical contribution”, Brazilian Journal of Operations & Production Management, Vol. 15, No. 4, pp. 558-565, available from: https://bjopm.emnuvens.com.br/bjopm/article/view/547 (access year month day).