Proposal and evaluation of a method to implement the lean construction principles

Marcelo Fabiano Costella

costella@unochapeco.edu.br

Community University of Chapecó Region – Unochapecó, Santa Catarina, Rio Grande do Sul, Brazil

Gustavo Bugnotto

gustavob@unochapeco.edu.br

Community University of Chapecó Region – Unochapecó, Santa Catarina, Rio Grande do Sul, Brazil

Analice Pinzon

analice_pinzon@hotmail.com

Community University of Chapecó Region – Unochapecó, Santa Catarina, Rio Grande do Sul, Brazil

Paulo Eduardo Lopes

lopes.peres@hotmail.com

Community University of Chapecó Region – Unochapecó, Santa Catarina, Rio Grande do Sul, Brazil

Francieli Dalcanton

fdalcanton@unochapeco.edu.br

Community University of Chapecó Region – Unochapecó, Santa Catarina, Rio Grande do Sul, Brazil

ABSTRACT

Since there is a gap between the concepts of the lean construction philosophy and an effective method of implementation in construction companies, the objective of this paper is to propose and evaluate a method to implement the lean construction principles. The method was constructed and evaluated through the application during 120 days of an action research in a pre-cast concrete company involving both researchers and the members of the company. The lean construction implementation method has three stages (preparation, application, and deployment), and it consists of three steps in each stage, totaling 9 steps. The evaluation of the method was satisfactory since the application was methodologically successful. In addition, it resulted in a cycle time reduction of 23.5% and the share of value-adding activities increased from 57.8% to 72.6%.

Keywords: Lean Construction; Implementation Method; Civil Production.

1 INTRODUCTION

The construction industry continues to seek improvements in the construction process, be it to improve speed and flexibility, lower costs or increase the quality of its processes and products. In order to meet these demands, construction companies are pursuing methods to improve the efficiency and effectiveness of their processes (Dave et al. 2016).

Lean construction is a widespread philosophy (Koskela 1992), which is based on the Toyota Production System and aims to reduce waste and focus on the customer. Despite its spread, based on several studies (Alarcon et al. 2011; Sage et al. 2012; Erol et al. 2017), the implementation of lean construction is still a challenge in developing countries, such as China (Shang and Pheng 2014; Ko and Kuo 2015; Li et al. 2017), Hong Kong (Ng et al. 2016), the United Arab Emirates (Small et al. 2017), India (Devaki and Jayanthi 2014) and Brazil (Barbosa et al. 2013; Tonin and Schaefer 2013; Souza and Cabette 2014).

Even with the spread of the lean production concepts, a gap can be observed between the concepts and an effective method of implementation in construction companies (Alves et al. 2012; Tillmann 2014; Tommelein 2015), as well the literature presents only Lean Construction principles diagnostics through the companies (Nesensohn et al. 2014; Bygballe and Sward 2014; Christoph 2014; Erol et al. 2017; Lucena and De Mori 2018). Such as the application of lean tools, such as 5S, Six Sigma, Kaizen, Kanban, and others, in construction environment (Kemmer et al. 2006; Marzouk et al. 2011; Shang and Sui Pheng 2013).

Therefore, the objective of this article is to propose and evaluate a method to implement the Lean Construction principles.

2 LITERATURE REVIEW

What is Lean Construction?

Lean Construction is a new view of production which focuses on the pursuit of excellence in production processes in civil construction environments, and Koskela (1992) explains the term lean as the use of less, in all aspects, when compared with mass production. Since relevant reductions are achieved through the lean philosophy, it is common to find satisfaction in the companies that adhere to this model of production (Nesensohn et al. 2014).

Koskela (1992) emphasizes that a reform in the current method of managing the construction must be performed, characterizing the sector as a focused conversion activity and stating that the traditional methods violate the flow and improvement principles.

Construction is fundamentally different from the manufacturing that gave rise to lean manufacturing. The transformation of constructive processes into manufacturing can be easy in small projects; however, it is very complicated to apply in more complex and unpredictable projects. To this end, a lean mentality must be developed adapted to this dynamic construction case (Ballard and Howell 1996)

Ever since lean construction (LC) spread all over the world, it has had to be adapted to both the country's culture and the company implementing it in order to be successful (Wandahl 2014).

Despite the peculiarities of the civil construction sector, there are also some barriers and success factors for the implementation of LC, the Critical Success Factors (CSF). In the definition of each identified factor, the barriers are grouped into master factors and categories (Cano et al. 2015).

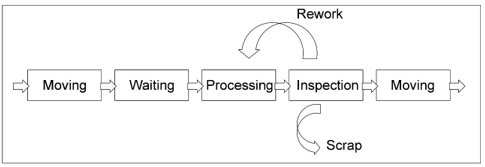

The new model comprises the processes as follows. Production is defined as a flow of material and/or information, from raw material to the final product. During this process, the material is necessarily located in one of these actions: processing, inspection, waiting and moving (Figure 1). These activities are inherently different, with processing representing the product conversion aspects, while inspection, moving and waiting represent the production flow (Koskela 1992).

Figure 1. Lean construction process model

Source: Formoso (2000)

The workflow processes are characterized by time, cost and value. Value can be understood as the fulfillment of customer requirements and processing activities. Usually, these are activities that add value to the product. For the flows of material, the processing activities are those that cause changes in form or substance, assembly or disassembly.

The conceptual foundation of this theory implies a new way of understanding productive processes, which from the perspective of LC are defined as conversion and flow. Koskela (1992) also stresses that the global efficiency of production is also linked to the level of technology, skill and motivation with regard to the undertaken conversion activities, in addition to the quantity and efficiency of flow activities.

The generation of value also characterizes the lean construction processes. This concept is directly linked to customer requirements and satisfaction, whether they are internal or external customers. This way, a process only creates value when these requirements are met. On the other hand, rework is directly linked to products that have not reached the specifications of the customers and, therefore, had to be redone or repaired, which means that the processing activities were executed without value-adding (Formoso 2000).

Lean Construction Principles

For Koskela (2000), the most important principles for the control and improvement of the production system can be divided into three types. The first, the conceptual foundation of this theory, indicates the fundamental source of improvement:

- Reduce the share of non-value-adding activities: the value of the product is defined as a function of the satisfaction of customer requirements. Once this has been defined, it is important to identify and eliminate any non-value-adding activity.

- Increasing output value: for each performed activity, two types of a customer can be identified; the one of the next activity and the end customer, and both must have their demands met. Consequently, the process increases output value if it meets the needs of internal customers and end customer.

The second type includes those principles that can be derived from the theory:

- Reducing the cycle time: this principle arises from the Just in Time philosophy and consists in performing the processes at the right time, with the cycle time reduction being defined as the sum of all the times required for the manufacture of a single product.

- Reducing variability: the variability may result from suppliers, the process itself or customer demands. One example of variability is the dimensional variation of the materials delivered at the work site.

The third type includes those principles that have been observed as useful in practice, but are not directly linked to the theory:

- Simplification by minimizing the number of steps, parts and linkages: the simplification of procedures focuses on the elimination of waste. The more steps and parts each product needs in order to be produced, it is necessary to reduce de share of non-value-adding activities.

- Increasing output flexibility: the flexibilization of the manufacture of a product is required due to the variations and different characteristics of each customer. Although this may seem contradictory with regard to the simplification principle, some key elements are contained in the design of a modular product in connection with the aggressive use of cycle time reductions and transparency.

- Increasing process transparency: transparency is important to eliminate errors, reduce waste, and increase the motivation for improvement.

Two important aspects need to be made clear for the deployment of the 7 principles. The first aspect is that the implementation model sustaining the application of the principles has a beginning and an end, and it can be repeated countless times. The second is that the principles need to be part of the essence of the organization so they permeate into all levels of the company, as part of the organizational thinking (Salem et al. 2005). For Bygballe and Sward (2014), LC is not a ready-for-use concept, but rather a process to engage various organizational levels, consisting of a continuous learning process.

3 METHOD

The proposal of the implementation method of the Lean Construction (LC) principles consisted of a detailed study of the LC principles and was carried out through an action research in a reinforced concrete precast plant.

An action research is characterized by performing a research in conjunction with solving a problem, in which the researchers and participants are involved in a cooperative and/or participatory way (Patton 2011; Thiollent 2011).

Based on the gap between the LC principles and in view of the experience of the research team (researcher has an 18-year experience in LC studies and corporative people had postgraduation degree in production engineering) the implementation method of implementation in construction companies was designed. The proposal of the method began to be developed by the team of researchers using the project management practices as foundation (Project Management Institute 2014), in a concomitant way to the deployment of these processes within the company, to take the format of a 3-stage project, with the first being the preparation, the second the basic application of the LC principles and the third step the effective implementation and evaluation. This proposition was molded, along with the implementation process, in five 3-hour meetings with only the researchers and three 1-hour meetings with the participation of researchers and the company.

The entire implementation process was performed in 120 days due to the research deadline of the project (30 days for Preparation, 60 days for Application and 30 days for Deployment), but it was only possible due to the company's commitment to the implementation of the model in which it participated; a fundamental factor for the success of the deployment.

The reinforced concrete precast plant is located in Brazil, in western Santa Catarina and it has 38 employees. This plant is part of a cooperative founded more than 40 years ago, it is active in the most diverse branches of engineering, including the construction of small hydroelectric power plants and grain storage silos, and it has around 800 employees.

4 PROPOSAL OF THE LC IMPLEMENTATION METHOD

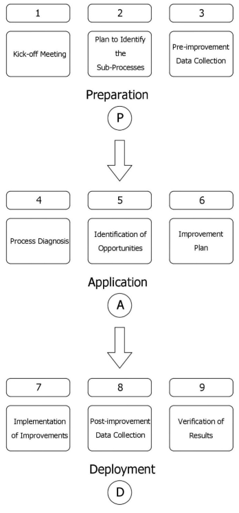

The implementation method of the Lean Construction philosophy consisted of three stages:

1 - Preparation: foundational work to receive the LC concepts,

2 - Application: use of the LC concepts and principles,

3 - Deployment: implementation of the solution measures and verification of results;

The 3 stages (PAD) are composed of 9 steps, as shown in Figure 2:

Figure 2. Stages of the Lean Construction philosophy implementation method

Source: The authors (2018).

Step 1 - Kick-off Meeting

The holding of this meeting is a milestone for the start of the deployment and it seeks to make managers understand the objective and assist in promoting the engagement and awareness of all those involved in the organization. At this meeting, the entire implementation method is presented and some task assignments are carried out in order to facilitate the start of the implementation.

Step 2 - Plan to Identify the Sub-Processes

The processes should be identified according to the configuration of the construction activity, as a function of the uniqueness of each work, in order to get the best representation of its processes, whether it is the construction project for a building, pavement, hydroelectric plant or electromechanical assembly, among others.

This identification is a map of the construction processes, which can be developed with lists, diagrams and graphical representations. The identification of the processes is the foundation to define the construction sub-processes, especially regarding how each sub-process interacts and how these flows work.

Step 3 - Pre-improvement Data Collection

To understand the current performance of construction activities, a data collection record of sufficient quality is required so it can be analyzed appropriately. If there are not sufficient data, the data collection quality must be reviewed, establishing new standards and checking the new collection.

The way this data is presented and controlled is usually conditioned by the type of construction activity and usually consists of the parameters the organization uses to control its indicators.

A simple example of a similar activity that can be seen in different ways is the assembly of formworks for reinforced concrete parts, where you can use conventional formworks with production indicators in square meters or sliding formworks, which use slid meters as a standard measurement.

Step 4 - Process Diagnosis

The diagnosis of the process is necessary to obtain a full understanding of the functioning of the activities, their relationships and flows. To understand this scenario, the seven principles of Lean Construction must be applied in order to identify which activities are subject to:

- Reducing the share of non-value-adding activities;

- Increasing output value by taking customer requirements into account;

- Reducing the cycle time;

- Reducing variability;

- Simplification by minimizing the number of steps, parts, and linkages;

- Increasing output flexibility;

- Increasing process transparency.

The seven principles should be applied in each sub-process based on a detailed analysis of each sub-process. Interviews should be conducted with the professionals involved in the activities in order to get a better understanding of some events already observed in the visual analysis.

Support tools, such as software, for the development of process flows, mental maps or spreadsheets can contribute to this diagnosis process. The information generated here should be compiled and spread so it reaches all stakeholders.

Step 5 - Identification of Opportunities

In this step, all information must be analyzed, since it is now available to all employees. The goal now is to analyze the 7 principles of Lean Construction to evaluate each issue raised in the diagnostic process. Whenever possible, this should involve one or more answers and solution alternatives for the issues raised in Step 4. After the completion of all responses, it is essential to proceed with two more steps: a) What can be done? b) What will be done?

In step I, the managers should list the proposed improvements, and it is up to them, in this case, to exclude those alternatives which are deemed unfeasible at the current time. In step II, the priorities should be established and assistance should be given to the development of an action plan to organize the change.

Step 6 - Improvement Plan

It is a detailed implementation plan, usually developed by the planning sector, which employs appropriate techniques and tools for planning and controlling the implementation activities. Through this plan, it is possible to visualize when each implementation step will be concluded.

Step 7 - Implementation of Improvements

In this step, all actions defined in the previous steps are put into practice, following the planning priorities. Those responsible should have autonomy to implement the improvements of the implementation plan, execute orders and approve purchase requests whenever necessary if they are within the preset limits defined by the organization.

Step 8 - Post-improvement Data Collection

This is the data collection on the process data with the improvement actions already deployed. This collection can be done gradually as the implementation of each sub-process is concluded.

Step 9 - Verification of Results

This is the time to analyze the data and compare the operating conditions of the production system at two times, before and after the implementation of the Lean Construction philosophy. When performing this evaluation, it is necessary to share the obtained results with all stakeholders. With the end of this implementation cycle, it is recommended that the company reorganizes itself periodically and repeats the application of the method, seeking the best performance of its construction process and the spreading the Lean Construction philosophy as part of the company's culture.

5 EVALUATION OF THE IMPLEMENTATION METHOD

Step 1 - Kick-off Meeting

A Kick-off meeting was held with the director of the company, a plant manager, a production manager, and the civil engineer in charge. At this time, all parties were made aware of their responsibilities to promote the improvement processes as they were needed.

Step 2 - Plan to Identify the Sub-Processes

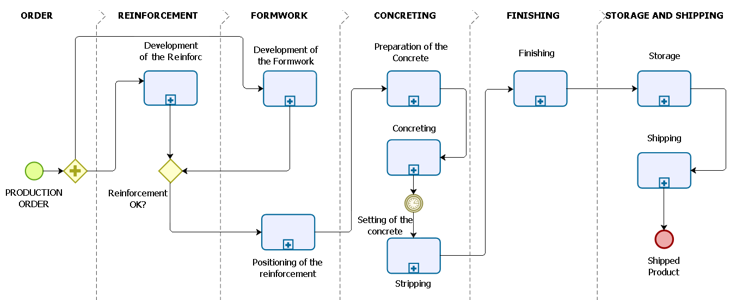

The sub-process identification plan was developed with a mapping of the processes of each activity with the aid of the Bizagi Studio software. It was decided to evaluate the manufacturing process of a precast concrete beam. The sub-processes were identified and analyzed in the following manner: reinforcement, formworks, concreting, finishing, storage and shipping.

Figure 3. Production Flow Diagram

Source: The authors (2018).

In the definition of the sub-processes, the activities of the sub-processes were regarded as connected, thus providing a continuous flow from the entry of the order, passing through all the processes and internal customers until the shipping of the product to the work site or inventory. This is shown in Figure 3, starting with the production order coming from the engineering sector until the last stage of the process, the shipment and/or storage.

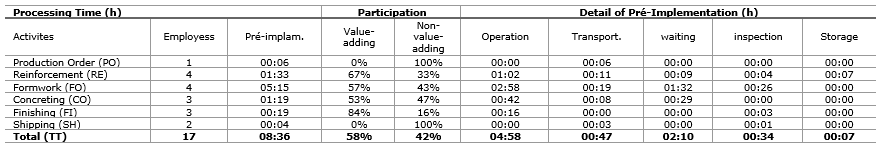

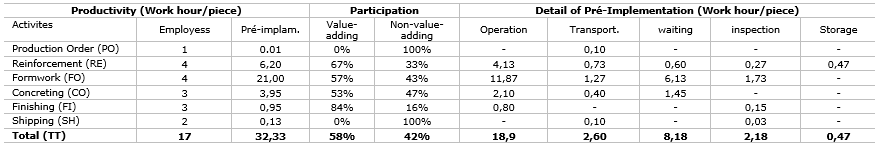

Step 3 - Pre-improvement Data Collection

The pre-improvement data collection measured the cycle time of the company's sub-processes and each physical and information flow, and was quantified from two perspectives: time and resources, in a detailed manner. The collections were separated considering the execution (operation), waiting, and transport times. The curing time is not included since employees are involved in other tasks while waiting for this to complete. Data collection can be seen in tables 1 and 2, as it depicts the current processing conditions of the plant in terms of time and productivity.

Table 1. Current processing time of the plant

Source: The authors (2018).

Table 2. Current productivity of the plant

Source: The authors (2018).

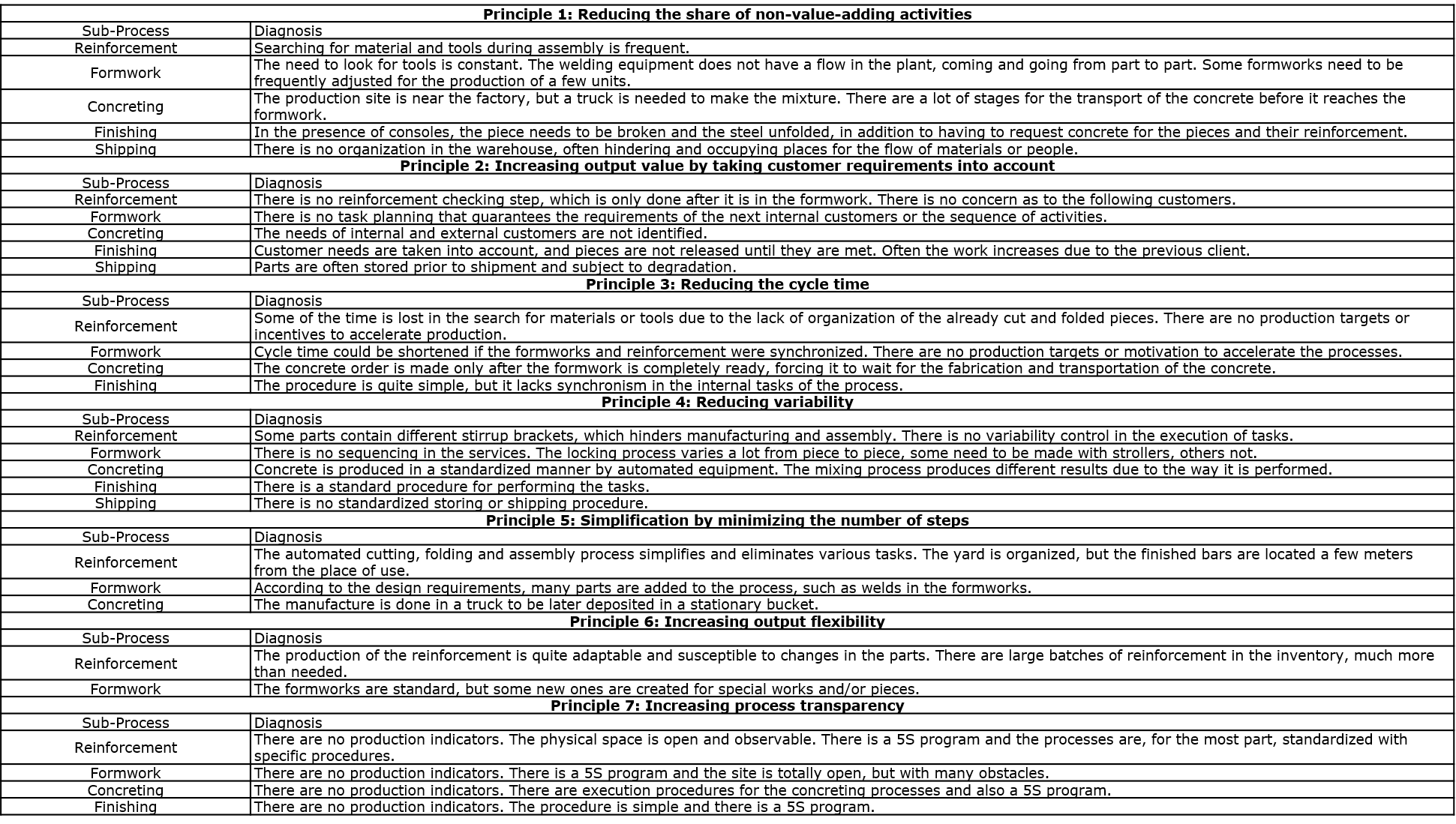

Step 4 - Process Diagnosis

The process diagnosis is based on the analysis of the data gathered in the previous step, through which it is possible to estimate the productive quantity at the company within its quality standards and also to find out what are the most important and representative processes in the manufacture of the precast structure.

The total production time of the monitored piece was 8h36min and involved 17 employees, with a large waste being observed in the waiting process, in addition to more than 40% of non-value-adding activities. The distances traveled were also observed for the physical flows in the sectors:

- Reinforcement: Distance traveled of approximately 100 m;

- Formworks: Distance traveled of approximately 110 m;

- Concreting: Distance traveled of 70 m.

Complementing the data of the current production situation of the plant, the visual monitoring of each sub-process was performed according to the seven principles outlined in Figure 4.

Figure 4. Diagnostics of principles 1 to 7

Source: The authors (2018).

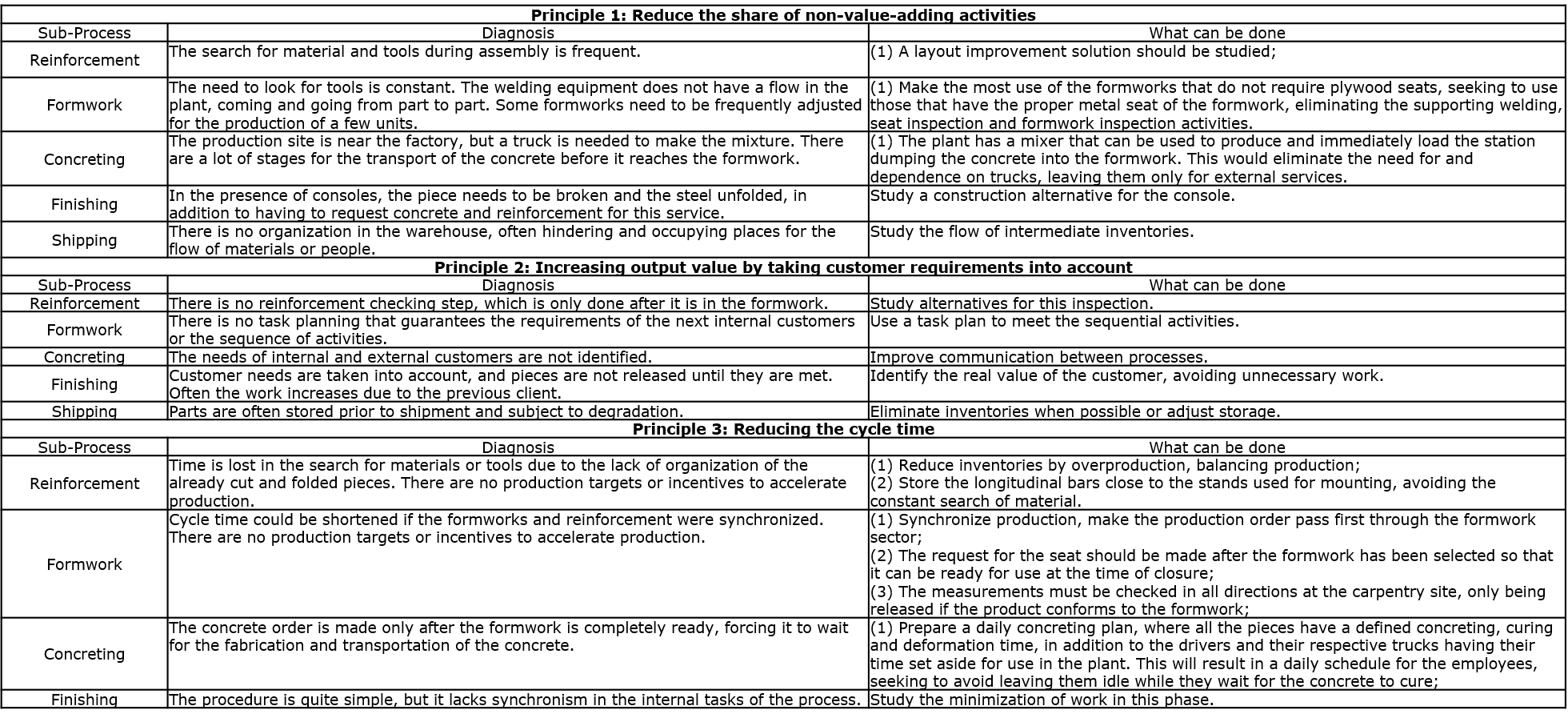

Step 5 - Identification of Opportunities

Based on the performed diagnosis and process analysis in the previous steps, it was possible to structure the diagnostic charts, listing the opportunities in the reinforcement, formwork and concreting sub-processes. Figure 5 shows the identified opportunities with the solution alternatives for the first three principles according to their importance. Some cases were not studied because of the priorities of the company; however, they were identified and will be dealt with by the company at a stage following this first application of the method.

Figure 5. Opportunities for principles 1 to 3

Source: the authors (2018).

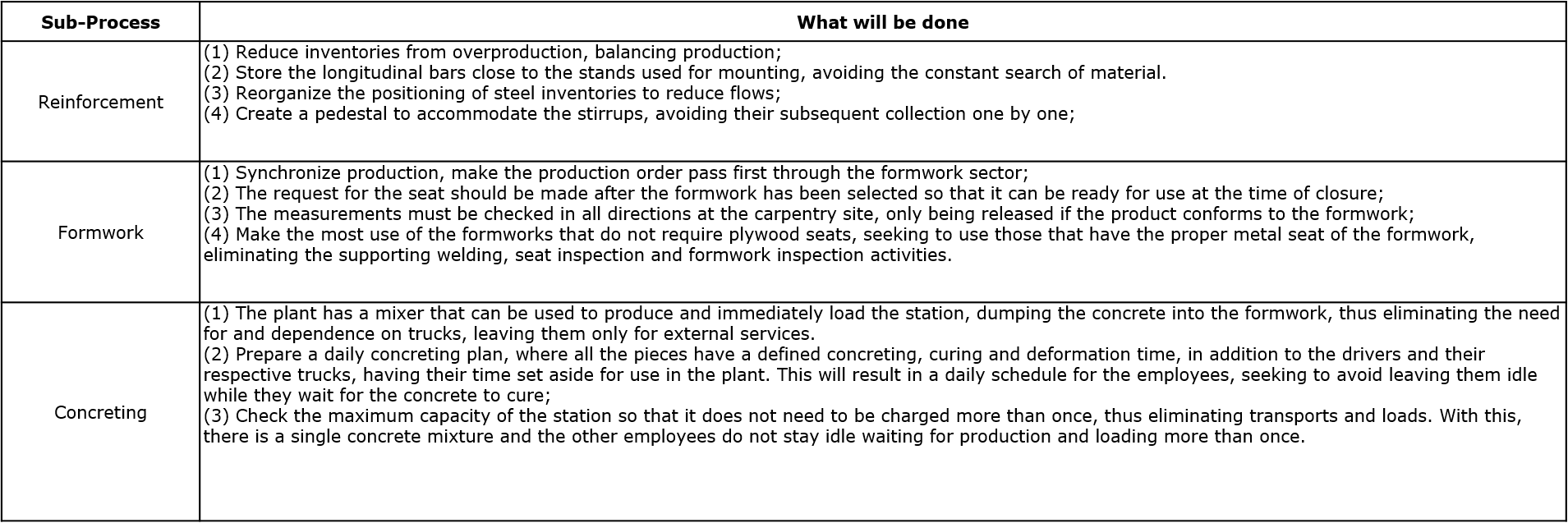

Step 6 - Improvement Plan

The improvement plan was drafted and distributed with a five-week deadline for completion. The plan took three sub-processes into account (reinforcement, formworks, and concreting), as identified and proposed in Step 3. The implementation priorities were defined and organized in Figure 6 by filling out the column "What will be done."

Figure 6. Priorities defined for reinforcement, formworks and concreting

Source: the authors (2018).

Step 7 - Implementation of Improvements

In the implementation of improvements, the activities were implemented as envisaged in the plan. The final deadline was met even though there was a small deviation in the deployment of the improvements for the reinforcement and formworks.

Step 8 - Post-improvement Data Collection

The second round of data collection was performed after the improvement implementation process, in the same way as in the first data collection round, providing equivalent data for the completion of the analysis of the results.

Step 9 - Verification of Results

The information was processed according to the production's cycle time and productivity after the improvement process was applied.

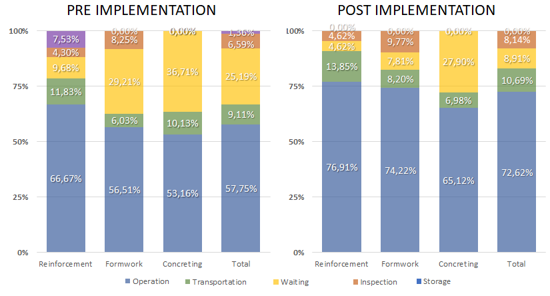

Figure 7. Pre and post-implementation time graph

Source: The author (2018).

After the implementation of the measures in the three sectors (Figure 7), the results reached 72.6% of value-adding activities (operation). Besides, the waiting activities in the formwork process went from 29.2% to 7.8%, totaling 8.9%. The total time spent on non-value-adding activities went from 42.2% to 27.4%.

The deployment caused a positive effect since, in general, the gains surpassed 23,5% in the production time cycle, which went from 8h36min to 6h33mim. The increase in the operational formwork activity also adds value to the product, as opposed to the waiting activity, which does not add value and was reduced by 78%. When the production conditions of the plant are observed in terms of value-adding and non-value-adding activities, the process ceased to operate in a range greater than 40% to a range lower than 30% of non-value-adding activities, proving to be more adequate for the new operating conditions.

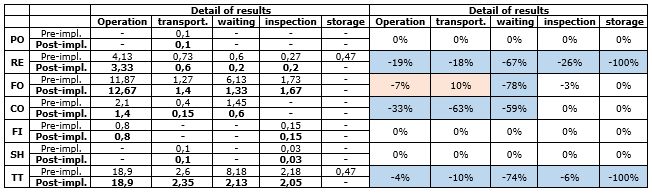

In terms of productivity (Figure 8), a large reduction in terms of waiting times (74%) can be seen, as well as reductions of 4% to 10% in the other operations.

Figure 8. Detail of the productivities before and after implementation

Source: The authors (2018).

6 CONCLUSIONS

This paper sought to present a new implementation method of the lean construction principles, in addition to the application of this method, for the purposes of evaluation, in a precast concrete company. The method proved to be easy and straightforward to implement given the company's prompt collaboration, and it resulted in overall productivity gains and a cycle time reduction of the process of 23.5%.

Another factor of note was the presentation of this method to the factory employees, who were able to observe the importance of the flows within production and their respective impacts. The great engagement of the employees and leaders of the factory in relation to the study should be highlighted, since they always contributed with information, opinions, and ideas for the development of this work in a variety of ways, from the data collection stage to the development of the proposals. One of the limitations is that the method was only applied to one family of products of the company due to the great variability of produced pieces.

As one of the implications, the article revealed that a structured lean construction implementation method enables the improvement of productivity of the company without large investments, through the control of productive processes and the elimination of non-value-adding activities. As a next step, the validation of this method in other environments of the construction industry is suggested.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the Chapeco Region Community University, which funded this project and to Paulo Eduardo Peres Lopes for helping to build the implementation model.

REFERENCES

Alarcón, L.F.; Diethelm, S.; Rojo, O.; Calderon, R. (2008), “Assessing the impacts of implementing lean construction”, Revista Ingeniería de Construcción, Vol. 23, No. 1, pp. 26–33.

Alves, T.C.L.; Milberg, C.; Walsh, K.D. (2012), “Exploring lean construction practice, research, and education”, Engineering, Construction and Architectural Management, Vol. 19, No. 5, pp. 512-525. doi: 10.1108/09699981211259595

Ballard, G.; Casten, M.; Howell, G. (1996), “A Case Study. In Proceedings of the 4th Annual Conference of the International Group of Lean Construction”, Birmingham, UK, 1996, International Group for Lean Construction.

Barbosa, B.; Andrade, F.; Biotto, C.; Mota, B. (2013), “Implementing Lean Construction Effectively in a Year a Construction Project”, In Proceedings of the 21th Annual Conference of the International Group for Lean Construction, Fortaleza, Brasil. International Group for Lean Construction, pp. 1017-1026.

Bygballe, L.; Sward, A. (2014), “Implementing Lean Construction: A Practice Perspective”. In Proceedings of the 22th Annual Conference of the International Group for Lean Construction, Oslo, Noruega. International Group for Lean Construction, pp. 3-14.

Cano, S.; Delgado, J.; Botero, L.; Rubiano, O. (2015), “Barriers and Success Factors in Lean Construction Implementation – Survey in Pilot Context”, In Proceedings of the 23th Annual Conference of the International Group for Lean Construction, Perth, Australia. International Group for Lean Construction, pp. 631-641.

Christoph, R. F. (2014), The presence of Lean Construction principles in Norways transport infrastructure projects. Theses Civil and Environmental Engineerin, Norwegian University of Science and Technology, Trondheim, Noruega.

Dave, B.; Kubler, S.; Främling, K.; Koskela, L. (2016), “Opportunities for enhanced lean construction management using Internet of Things standards”, Automation in Construction, Vol. 61, pp. 86-97.

Devaki, M.P.; Jayanthi, R. (2014), “Barriers to implementation of lean principles in the Indian construction industry”, International Journal of Engineering Research & Technology, Vol. 3, No. 5, pp. 1189–1192.

Erol, H.; Dikmen, I.; Birgonul, M.T. (2017), “Measuring the impact of lean construction practices on project duration and variability: A simulation-based study on residential buildings”, Journal of Civil Engineering & Management, Vol. 23, No. 2, pp. 241-252.

Formoso, C. T. (2000), Lean Construction: Princípios Básicos e Exemplos, available in: http://www.leansixsigma.com.br/acervo/2011520.PDF.

Kemmer, S.; Saraiva, M. A.; Heineck, L. F. M. et al. (2006), "The use of and on in high rise building", In Proceedings of the 14th Annual Conference of the International Group for Lean Construction, Santiago, Chile, International Group for Lean Construction, pp. 575-582.

Ko, C.; Kuo, J. (2015), Making formwork construction lean, Journal of Civil Engineering and Management, Vol. 21, No. 4, pp. 444–458.

Koskela, L. (1992), Application of the New Production Philosophy to Construction, Cife, Finland.

Koskela, L. (2000), An Exploration Towards a Production Theory and its Application to Construction, Vtt Publications, Espoo.

Li, S.; Wu, X.; Zhou, Y.; Liu, X. (2017), “A study on the evaluation of implementation level of lean construction in two Chinese firms”, Renewable and Sustainable Energy Reviews, Vol. 71, pp. 846-851.

Lucena, A.; De Mori, L. M. (2018), “Critical analysis of lean construction measuring tools”, Brazilian Journal of Operations & Production Management, Vol. 15, No. 2, pp. 311-321.

Marzouk, M.; Bakry, I.; El-Said, M. (2011), “Application of Lean Principles to Design Processes in Construction Consultancy Firms”, International Journal of Construction Supply Chain Management, Vol. 1, No. 1, pp. 43-55.

Nesensohn, C.; Bryde, D.; Ochieng, E.; Fearon, D. (2014), “Maturity and Maturity Models in Lean Construction”, Australasian Journal of Construction Economics and Building, Vol. 14, No. 1, pp. 45-59.

Ng, S.T.; Zou, W.; Wong, K.; Huang, G. Q. (2014), ”Lean Construction of Public Housing Production in Hong Kong: A Process-Based Approach”, In 40th IAHS World Congress on Housing, Funchal, Portugal, 16-19. Conference Proceedings, pp. 1-10.

Patton, M. Q. (2011), Developmental Evaluation: Applying Complexity Concepts to Enhance Innovation and Use, Guilford Press, New York.

Project Management Institute - PMI (2014), Um Guia do Conhecimento em Gerenciamento de Projetos (Guia PMBOK), 5. ed., Saraiva, São Paulo, SP.

Sage, D.; Dainty A.; Brookes, N. (2012), “A ‘Strategy-as-Practice’ exploration of lean construction strategizing”, Building Research and Information, Vol. 40, No. 2, pp. 221-230.

Salem, O.; Solomon, J.; Genaidy, A.; Luegring, M. (2005), “Site Implementation and Assessment of Lean Construction Technique”, Lean Construction Journal, Vol. 2, No. 2.

Shang, G.; Pheng, L. S. (2014), “Barriers to lean implementation in the construction industry in China”, Journal of Technology Management in China, Vol. 9, No. 2, pp. 155-173.

Shang, G.; Sui Pheng, L. (2013), "Understanding the application of Kaizen methods in construction firms in china", Vol. 8, No. 1, pp. 18-33.

Small, E. P.; Hamouri, K. A.; Hamouri, H. A. (2017), “Examination of Opportunities for Integration of Lean Principles in Construction in Dubai”, Procedia Engineering, Vol. 196, pp. 616–621.

Souza, B. C.; Cabette, R. E. S. (2014), “Gerenciamento da Construção Civil: Estudo da Aplicação da “Lean Construction” no Brasil”, Revista e Gestão & Tecnologia, Vol. 1, No. 2.

Thiollent, M. (2011), Metodologia da Pesquisa-Ação, 18 ed., Cortez, São Paulo.

Tillmann, P.; Ballard, G.; Tommeleim, I. (2014), “A Mentoring Approach to Implement Lean Construction”, In Proceedings of the 22th Annual Conference of The International Group of Lean Construction, Oslo, Noruega, International Group for Lean Construction, pp. 1283-1293.

Tommelein, I. D. (2015), “Journey toward Lean Construction: Pursuing a Paradigm Shift in the AEC Industry”, Journal of Construction Engineering and Management, Vol. 141, No. 6.

Tonin, L. A. P.; Schaefer, C. O. (2013), “Diagnóstico e aplicação da Lean Construction em Construtora”, Cesumar, Vol. 15, No. 1, pp. 23-31.

Wandahl, S. (2014), “Lean Construction with or without lean: Challenges of Implementing Lean Construction”, In Proceedings of the 22th Annual Conference of The International Group of Lean Construction, Oslo, Noruega. International Group for Lean Construction, pp. 97-108.

Received: 17 Jul 2018

Approved: 02 Nov 2018

DOI: 10.14488/BJOPM.2018.v15.n4.a8

How to cite: Costella, M. F.; Bugnotto, G.; Pinzon, A. et al. (2018), “Proposal and evaluation of a method to implement the lean construction principles”, Brazilian Journal of Operations & Production Management, Vol. 15, No. 4, pp. 545-557, available from: https://bjopm.emnuvens.com.br/bjopm/article/view/535 (access year month day).