Joint Replenishment Problem in Drug Inventory Management of Pharmacies under Stochastic Demand

Kizito Paul Mubiru

kizito.mubiru@yahoo.com

Kyambogo University, Kampala, Uganda

ABSTRACT

In today’s fast-paced and competitive market place, organizations need every edge available to them to ensure success in planning and managing the inventory of items with demand uncertainty. In such an effort, cost effective methods in determining optimal replenishment policies are paramount. In this paper, a mathematical model that optimizes inventory replenishment policies of a periodic review inventory system under stochastic demand is proposed, with particular focus on malaria drugs in Ugandan pharmacies. Adopting a Markov decision process approach, the states of a Markov chain represent possible states of demand for drugs that treat malaria. Using weekly equal intervals, the decisions in terms of whether or not to replenish additional units of drugs were made using discrete time Markov chains and dynamic programming over a finite period planning horizon. Empirical data was collected from two pharmacies in Uganda. The customer transactions of drugs were taken on a weekly basis, where the data collected was analyzed and tested to establish the optimal replenishment policy and inventory costs of drugs. Results from the study indicated the existence of an optimal state-dependent replenishment policy and inventory costs of drugs at the respective pharmacies.

Keywords: Inventory; joint replenishment; pharmacy; stochastic demand

1. INTRODUCTION

Joint replenishment inventory decisions are common in business enterprises and various models have been developed to support this function. In practice, hospital logistics must be improved by coordinating procurement and distribution operations while respecting inventory capacities (Lappiere and Luiz, 2007) where emphasis is put on scheduling decisions: when to buy and deliver products at pharmacies, when each employee should work and what task he should do. This is a great challenge when demand for drugs in pharmacies follows a stochastic trend. Two major problems are usually encountered: (i) determining the most desirable period during which to replenish additional units of the drug in question and (ii) determining the optimal replenishment policy and inventory costs, given a periodic review inventory system when demand is uncertain. In spite of the internal challenges to master the stochastic drug logistic flows, increased degree of robustness and flexibility (Jebbor et al., 2016), a kanban system was proposed to reduce and master the stochastic effect coming from suppliers. Hence, better quantitative models of the hospital medication are highly sought (Smith et al., 2017) for proper inventory management. However, current research is now paying more attention to the interdependencies between pharmaceutical supply chains and greater healthcare bundle (Narayana et al., 2014). Novel approaches however must be deployed to capture stochastic demand of drugs through technological advances and patient-centric inventory models. The paper is organized as follows: After reviewing the previous work done, a mathematical model is proposed where initial consideration is given to the process of estimating model parameters. The model is solved thereafter and applied to special case studies. Some final remarks follow with future research directions.

2. REVIEW OF INVENTORY MODELS IN THE PHARMACEUTICAL INDUSTRY

The modeling of inventory in pharmacies has been tackled in several ways, such as the use of the classical EOQ model under conditions of permissible delay in the payment of multiple products by using safety stock to anticipated stochastic demand (Jonrinaldi and Hadiguna, 2017). In this article, the authors develop a policy based on the actual condition of the system studied where suppliers provide a certain period of time to complete the payment of the order. Further extensions to address the concept of random demand as in Villa-Parrish et al. (2012) consider a perishable inventory problem where stochastic demand state is used as a surrogate for patient condition. Two ordering and production scenarios are defined to prove existence of optimal solutions for both scenarios. Additional insights as in Jurado et al. (2013) develop a chance-constrained predictive control model that takes into account the different objectives and constraints involved in the hospital stock management problem; which provides a trade-off between conservativeness and efficiency. A novel approach that handles the inventory problem in the pharmaceutical supply chain (Candan and Yazgan, 2016) establish a demand-driven classical supply chain model and shows its effectiveness using an experimental study that consists of two different supply chain policies. Finally, the model is compared to another model in literature and the results show that the proposed model is superior. The unique challenges associated with inventory decisions for pharmaceutical products as in Villa-Parish and Ivy (2013) indicate the broader implications of the impact of demand uncertainty and inventory management strategies on hospital operations and cost with particular focus on stationary and non-stationary demand scenarios. Using Simulation in inventory management of pharmaceuticals (Ebrahimzadeh et al., 1985), determining inventory ordering policies in a regional drug warehouse, is possible. In this article, the model developed is multi-item based with stochastic demand and lead time, periodic ordering, fixed ordering costs, shortage, and holding costs, varying from drug to drug. Since health has a major impact on the flow of information between physicians, between drug manufacturers and patients, and between pharmacists and patients (Negishi et al., 2003), clinical records between physicians’s offices and pharmacies can be shared with secure signature recognition and privacy. The author showed that a substantial amount of time was spent by pharmacists in counseling patients, which significantly increased patient anxiety. A work sampling study (Murray, Loos et al., 1998) also showed that the introduction of computer support in the prescription writing process significantly changed the type of work done by hospital based pharmacists. The shifts in work patterns as a result of the internet in health related problem solving over routine procedures has been discussed in other related literature (Landry et al., 2005).

The primary contributions of this paper to the literature on drug inventory management in pharmacies are as follows:

-

It illustrates how the demand transition matrix and total inventory (reward) matrix can be computed for a chosen set of drugs at pharmacy stores;

-

The computational procedure of expected inventory costs and accumulated inventory costs for the selected drugs at pharmacy stores is shown;

-

As a cost minimization strategy, the optimal least-cost drug replenishment policy was derived at the pharmacy drug stores.

3. MODEL DESCRIPTION

A set of pharmacies storing drugs for various customers was considered. Drugs for malaria are considered in this study. The demand for drugs during each time period over a fixed planning horizon at a given pharmacy (P) is classified as either favorable (denoted by state F) or unfavorable (denoted by state U) and the demand of any such period is assumed to depend on the demand of the preceding period. The transition probabilities over the planning horizon from one demand state to another may be described by means of a Markov chain. Suppose one is interested in determining an optimal course of action at pharmacy P, namely to replenish additional units of drug d (a decision denoted by R=1) or not to replenish additional units of drug d (a decision denoted by R=0) during each time period over the planning horizon, where R is a binary decision variable. Optimality is defined such that the minimum inventory costs are accumulated at the end of N consecutive time periods, spanning the planning horizon under consideration. In this paper, a two-period (N=2) planning horizon is considered for two pharmacies (P=2) and two drugs (d=2) of malaria.

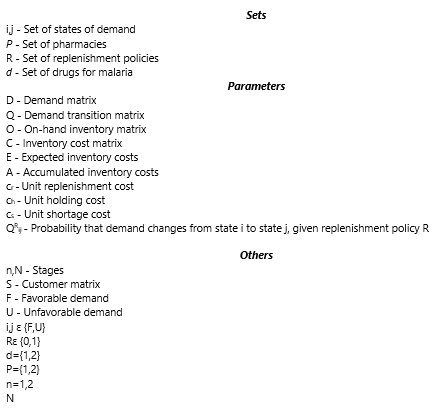

3.1 Notation

3.2 Finite-Period Dynamic Programming Formulation

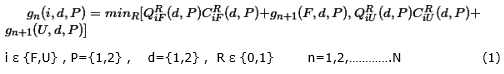

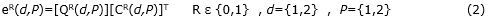

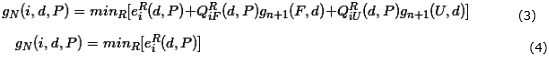

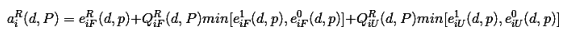

Recalling that the demand can either be in state F or in state U, the problem of finding an optimal replenishment policy can be expressed as a finite period dynamic programming model. Assuming gn(i,d,P) denotes the optimal expected inventory costs of drug d accumulated at the end of periods n,n+1,………….N at pharmacy P, given that the state of the system at the beginning of period n is i ε {F,U}.The recursive equation relating gn and gn+1 is

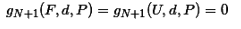

together with the conditions

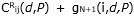

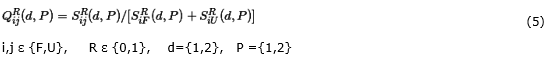

This recursive relationship may be justified by noting that the cumulative inventory costs  , resulting from reaching state j ε {F,U} at the start of period n+1 from state i ε {F,U} at the start of period n, occurs with probability

, resulting from reaching state j ε {F,U} at the start of period n+1 from state i ε {F,U} at the start of period n, occurs with probability  .

.

Clearly

where “T” denotes matrix transposition. Hence, the dynamic programming recursive equations

result where (4) represents the Markov chain stable state.

3.3 Computing QR(d,P) and CR(d,P)

The demand transition probability from state i ε {F,U} to state j ε {F,U}, given replenishment policy R ε {0,1}, may be taken as the number of drug d customers received at pharmacy P with demand initially in state i and later with demand changing to state j, divided by the sum of customers over all states. That is,

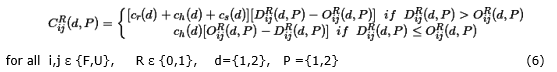

When demand outweighs on-hand inventory, the inventory cost matrix CR(d,P) may be computed by means of the relation

Therefore,

The justification for expression (6) is that  units must be replenished to meet excess demand. Otherwise replenishment is cancelled when demand is less than or equal to on-hand inventory.

units must be replenished to meet excess demand. Otherwise replenishment is cancelled when demand is less than or equal to on-hand inventory.

The following conditions must, however, hold:

-

R=1 when cr(d) > 0 and R=0 when cr(d)= 0

-

cs(d) > 0 when shortages are allowed and cs (d) = 0 when shortages are not allowed

4. OPTIMIZATION

The optimal replenishment policy and inventory costs are found in this section for drug d at pharmacy P during each period separately.

4.1 Optimization during period 1

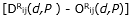

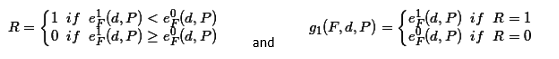

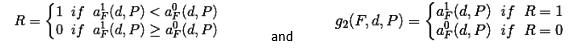

When demand is favorable (i.e. in state F), the optimal replenishment policy and inventory costs during period 1 are

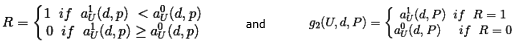

Similarly, when demand is unfavorable (i.e. in state U), the optimal replenishment policy and inventory costs during period 1 are, respectively:

4.2 Optimization during period 2

Using (3) and (4) and recalling that  denotes the already accumulated inventory costs of drug d for pharmacy P at the end of period 1, it follows that

denotes the already accumulated inventory costs of drug d for pharmacy P at the end of period 1, it follows that

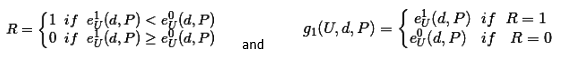

Therefore, when demand is favorable (i.e. in state F), the optimal replenishment policy and inventory costs during period 2 are, respectively:

Similarly, when demand is unfavorable (i.e. in state U), the optimal replenishment policy and inventory costs during period 2 are

5. A CASE STUDY ABOUT DRUGS AT ROMARO AND MEDIPHARM PHARMACIES IN UGANDA

In order to demonstrate the use of the model in §3-4, a real case application from two pharmacies, Romaro and Medipharm in Uganda, are presented in this section. Two drugs for malaria are considered in this study: P-Alaxin and Coartem. The demand for P-Alaxin and Coartem fluctuate every week at both pharmacies. The pharmacies want to avoid excess inventory when demand is unfavorable (state U) or running out of stock when demand is favorable (state F) and, hence, seek decision support in terms of an optimal replenishment policy and the associated inventory costs of P-Alaxin and Coartem drugs in a two-week planning period.

5.1 Data collection

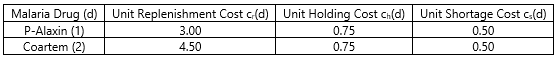

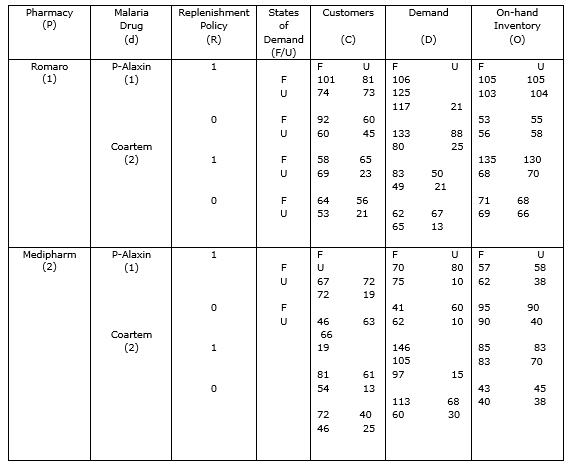

Samples of customers, demand, and inventory positions were taken for P-Alaxin and Coartem drugs (in packets) at the respective state-transitions. The samples were taken for twelve weeks at the respective replenishment policies. The unit replenishment cost (cr), unit holding cost (ch), and unit shortage cost (cs) of P-Alaxin and Coartem were similarly taken. In addition, relationships between customers, demand, on-hand inventory, replenishment policies and state transitions were taken. The data is presented in Table 1 and Table 2.

Table 1. Unit inventory costs (in US$) per packet

Table 2. Customers, Demand and On-hand inventory of drugs for malaria (in packets), given states of demand and replenishment policies at pharmacies

Source: Compiled from Medipharm and Romaro Pharmacies in Uganda

5.2 Computation of Model Parameters

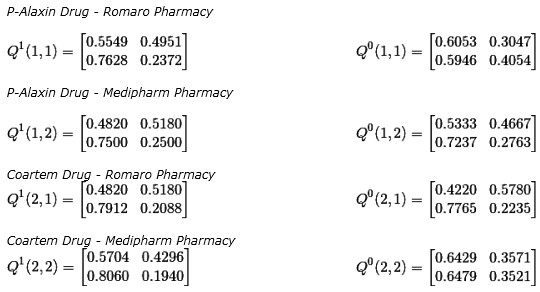

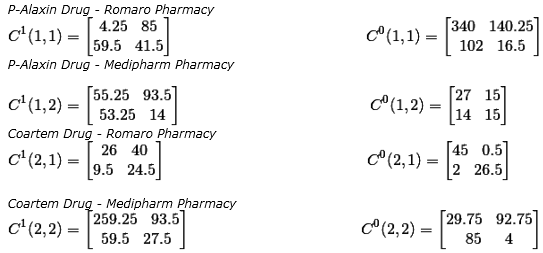

Using (5) and (6), the state-transition matrices and inventory costs (in US$) of P-Alaxin and Coartem drugs at pharmacies during week 1 are calculated as follows:

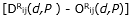

Demand Transition Matrices of Drugs at Pharmacies

Using (6), the total inventory cost matrices (in US$) are obtained for each drug at the respective pharmacies as follows:

Total Inventory Cost Matrices of Drugs at Pharmacies

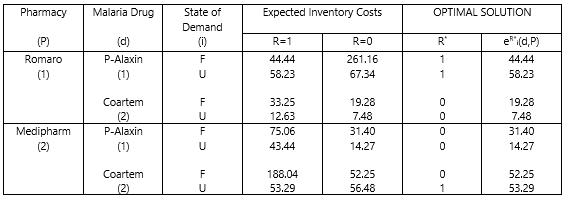

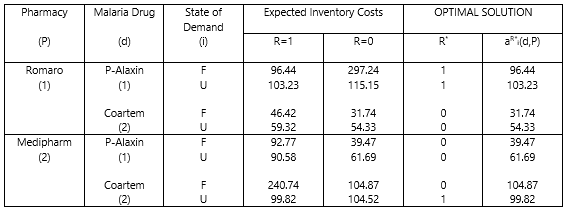

Using (2) and (3), the optimal expected inventory costs, accumulated inventory costs and replenishment policies are computed for each drug at the respective pharmacies. The results are summarized in Table 3 and Table 4.

Table 3. Optimal Replenishment Policies and Expected Inventory costs (in US$) of Drugs for Malaria at Pharmacies, given States of Demand in Week 1

Table 4. Optimal Replenishment Policies and Accumulated Inventory costs (in US$) of Drugs for Malaria in Pharmacies, given States of Demand in Week 2

5.3 The Optimal Replenishment Policy and Inventory costs of Drugs at Pharmacies

Romaro Pharmacy

Week 1:

At Romaro pharmacy, since 44.44<261.16, it follows that R=1 is an optimal replenishment policy for P-Alaxin drug with associated expected inventory costs of US$ 44.44 for the case of favorable demand. Since 58.23<67.34, it follows that R=1 is an optimal replenishment policy for P-Alaxin drug with associated expected inventory costs of US$ 58.23 for the case when demand is unfavorable.

Since 19.28<33.25, it follows that R=0 is an optimal replenishment policy for Coartem drug with associated expected inventory costs of US$ 19.28 for the case of favorable demand. Since 7.48<12.63, it follows that R=0 is an optimal replenishment policy for Coartem drug with associated expected inventory costs of US$ 7.48 for the case when demand is unfavorable.

Week 2:

Since 96.44<297.24, it follows that R=1 is an optimal replenishment policy for P-Alaxin drug with associated accumulated inventory costs of US$ 96.44 for the case of favorable demand. Since 103.23<115.15, it follows that R=1 is an optimal replenishment policy for P-Alaxin drug with associated accumulated inventory costs of US$ 103.23 for the case when demand is unfavorable.

Since 31.74<46.42, it follows that R=0 is an optimal replenishment policy for Coartem drug with associated accumulated inventory costs of US$ 31.74 for the case of favorable demand. Since 54.33<59.32, it follows that R=0 is an optimal replenishment policy for coartem drug with associated accumulated inventory costs of US$ 54.33 for the case when demand is unfavorable.

Medipharm Pharmacy

Week 1:

At Medipharm pharmacy, since 31.40<75.06, it follows that R=0 is an optimal replenishment policy for P-Alaxin drug with associated expected inventory costs of US$ 31.40 for the case of favorable demand. Since 14.27<43.44, it follows that R=0 is an optimal replenishment policy for P-Alaxin drug with associated expected inventory costs of US$ 14.27 for the case when demand is unfavorable.

Since 52.25<188.04, it follows that R=0 is an optimal replenishment policy for Coartem drug with associated expected inventory costs of US$ 52.25 for the case of favorable demand. Since 53.29<56.48, it follows that R=1 is an optimal replenishment policy for Coartem drug with expected inventory costs of US$ 53.29 for the case when demand is unfavorable.

Week 2:

Since 39.47<92.77, it follows that R=0 is an optimal replenishment policy for P-Alaxin drug with associated accumulated inventory costs of US$ 39.74 for the case of favorable demand. Since 61.69<90.58, it follows that R=0 is an optimal replenishment policy for P-Alaxin drug with associated accumulated inventory costs of US$ 61.69 for the case when demand is unfavorable.

Since 104.87<240.74, it follows that R=0 is an optimal replenishment policy for Coartem drug with associated accumulated inventory costs of US$ 104.87 for the case of favorable demand. Since 99.82<104.52, it follows that R=1 is an optimal replenishment policy for Coartem drug with associated accumulated inventory costs of US$ 99.82 for the case when demand is unfavorable.

6. CONCLUSIONS AND DISCUSSION

A stochastic inventory model for managing drugs in pharmacies was presented in this paper. The model determines an optimal replenishment policy and inventory costs of drugs for malaria under demand uncertainty. The decision in terms of whether or not to replenish additional units of drugs at a specific pharmacy is made using dynamic programming over a finite period planning horizon. Results from the model indicate optimal replenishment policies and inventory costs for the joint replenishment problem at each pharmacy. As a cost minimization strategy for joint replenishment problems in pharmacies, computational efforts of using Markov decision process approach provide promising results.

However, further extensions of the research are crucial to analyze the impact of non-stationary demand on replenishment policies. In the same spirit, the model developed raises a number of salient issues to consider: lead time of drugs during the replenishment cycle and customer response to abrupt changes in price of drugs at the chosen pharmacies. Special interest is also sought for further extending the model by considering the joint replenishment problem for optimal replenishment policies and inventory costs in the context of continuous-time Markov Chains (CTMC). The model developed is therefore expected to be amenable to some formal, logical or systematic analysis. The stochastic inventory model developed is to allow its application in the specific form in order to assist users achieve specific purposes.

As noted in the study, inventory cost comparisons were vital in determining the optimal replenishment policy and inventory costs at the two pharmacies in the case study. By the same token, a classification of demand as a two-state Markov chain facilitated modeling and optimization of replenishment policies and inventory costs at the pharmacies. In comparison to the theoretical periodic review inventory policies with a fixed order interval, whose inventory replenishment is checked to meet a pre-specified level, the stochastic inventory model developed shows important results. In practice, periodic review policies tend to carry large safety stock; increasing inventory holding costs. The stochastic inventory model proposed, however, makes cost comparisons of ordering versus not ordering and selects the lowest cost policy. In effect, the time dimension as a dominant characteristic is directly addressed for global competitiveness.

Managerial implications of the study give constructive suggestions to managers in the pharmaceutical industry that handle drugs with random demand patterns. If a manager keeps too little inventory, he risks losing sales and customers from stock outs. However, keeping too much inventory will require more space, transportation, handling, labor, and capital. Therefore, simplistic inventory stocking policies within a pharmacy can lead to substantial inefficiencies. Because inventory ties up a lot of capital, the stochastic inventory model proposed provides a basis for sound inventory policies in pharmacies. Managers can reconsider the flaws in supplier logistics process and minimize stock outs or excessive inventories as a cost minimization strategy.

REFERENCES

Candan, G.; Yazgan, H. (2016), “A novel approach for inventory problem in the pharmaceutical supply chain”, DARU Journal of Pharmaceutical sciences, Vol. 24, No. 4.

Ebrahimzadeh, M. et al. (1985) “A Simulation of a multi-item dry inventory system”, Simulation, Vol. 45, No. 3, pp. 115-21.

Jebbor, S. et al. (2016), “Management and control of stochastic drug supply chain by KANBAN and PetriNet”, in: 3rd International Conference of Logistics Operations Management, 23-25 May 2016.

Jonrinaldi, P. M.; Hadiguna, R. A (2017), “Joint Inventory Policy under permissible delay in payment and stochastic demand (Case study: Pharmacy Department of Pariaman Hospital)”, AIP Conference Proceedings, Vol. 1902, 1st ed.

Jurado, J. et al. (2013), Stock Management in Hospital Pharmacy using Chance-constrained model predictive control, Pharmaceutical Project (P12-TIC2400), November 2013

Landry, B. J. L. et al. (2005), “The changing nature of work in the age of e-business”, Journal of Organizational Change Management, pp. 132-44.

Lapierre, S.D., Ruiz, A.B. (2007), Scheduling logistic activities to improve hospital supply systems, Computers and Industrial Engineering, Vol. 34, No. 3, pp. 624-41.

Narayana, S. A. et al. (2014), “Managerial Research on the Pharmaceutical Supply chain-A critical review of some insights for future directions”, Journal of Purchasing and Supply Management, Vol. 20, No. 1.

Negishi, E. et al. (2003), “Electronic links between hospitals or clinics and pharmacies: Structure and operation of WAKASHIO pharmacotherapeusis network”, Yakugasha Zasshi, Vol. 123, No. 3, pp. 191-200.

Smith, K. et al. (2017), “A Simulation Approach for Evaluating Medication Supply chain structures”, International Journal of Systems Science, Vol. 4, No. 1.

Villa-Parrish, A. R. et al. (2012), “Patient-based pharmaceutical inventory management: A two-stage inventory and production model for perishable products with Markovian demand”, Health Systems, Vol. 1, No. 1, pp. 69-83.

Villa-Parrish, A. R., Ivy, J. S. (2013), “Managing supply chain to patient care: An Introduction to Hospital Inventory Management for pharmaceuticals”, Handbook of Healthcare Operations Management, pp. 447-67.

Received: 24 Jan 2018

Approved: 08 May 2018

DOI: 10.14488/BJOPM.2018.v15.n2.a12

How to cite: Mubiri, K. P. (2018), “Joint Replenishment Problem in Drug Inventory Management of Pharmacies under Stochastic Demand”, Brazilian Journal of Operations & Production Management, Vol. 15, No. 2, pp. 302-310, available from: https://bjopm.emnuvens.com.br/bjopm/article/view/446 (access year month day)