Optimization of machining parameters during Drilling by Taguchi based Design of Experiments and Validation by Neural Network

Reddy Sreenivasulu

rslu1431@gmail.com

Rvr&Jc College of Engineering, India

Chalamalasetti Srinivasarao

csr_auce@yahoo.co.in

Andhra University, Visakhapatnam

ABSRACT

Drilling is a hole making process on machine components at the time of assembly work, which are identify everywhere. In precise applications, quality and accuracy play a wide role. Nowadays’ industries suffer due to the cost incurred during deburring, especially in precise assemblies such as aerospace/aircraft body structures, marine works and automobile industries. Burrs produced during drilling causes dimensional errors, jamming of parts and misalignment. Therefore, deburring operation after drilling is often required. Now, reducing burr size is a serious topic. In this study experiments are conducted by choosing various input parameters selected from previous researchers. The effect of alteration of drill geometry on thrust force and burr size of drilled hole was investigated by the Taguchi design of experiments and found an optimum combination of the most significant input parameters from ANOVA to get optimum reduction in terms of burr size by design expert software. Drill thrust influences more on burr size. The clearance angle of the drill bit causes variation in thrust. The burr height is observed in this study. These output results are compared with the neural network software @easy NN plus. Finally, it is concluded that by increasing the number of nodes the computational cost increases and the error in nueral network decreases. Good agreement was shown between the predictive model results and the experimental responses.

Keywords: Drill thrust; Burr size; Aluminium 2014 alloy; Taguchi design of experiments; Neural network.

1. INTRODUCTION

Drilling operations usually produce burrs on both the entrance and the exit surfaces of the work piece. It is formed as a result of plastic deformation, which depends in large measure on the ductility of the material. Drilling burrs are the main handicap to reach the automation of assembly processes because of the necessity of deburring operations. Burrs are a source of dimensional errors, jamming and misalignment. They may cause short circuits in electrical parts, reduce the fatigue life of components or act as a crack initiation point (Gillespie, 1999; Aurich et al., 2009). For these reasons, the reduction of quality in drilling processes is a critical problem for the aeronautics and aerospace industries. Small burrs are allowed, but they have to be below a certain height. Therefore, deburring operation after drilling is often required. In aeronautics assembly, the components to be joined are drilled in stacks (multi-layers). Once the holes are made, components have to be separated in order to deburr and remove the remaining lubricant or chips. This means an additional work which can reach 30% of the total machining costs in precision operations (Aurich et al., 2009). Most of these problems are related to exit burr because it is much larger than that in the drill entrance. Hence, most research on this topic is often focused on the development of strategies to minimize exit burr.

1.1 Neural Network

An Artificial Neural Network (ANN) is: “an information processing paradigm, such as the brain, is the process information. The key element of this paradigm is the structure of the information processing system. It is composed of a large number of highly interconnected processing elements called neurons working in unison to solve specific problems. ANNs can be used to identify patterns and trends from complex or vague data that are very complicated to recognize by human being or other computer techniques. The ANN has to be trained using a learning process. The trained network can then be used to gain insight into new situation and to answer “what if” questions. Because of their immense ability to identify patterns or trends in data they have been greatly used in many applications, including forecasting, industrial process control, customer research, data validation, and risk management, etc. There are various types of neural networks available, such as feed forward neural network with single- and multi-perceptron, Adaline, radial basis function, and Kohenen self-organizing map. Among them, the feed forward networks are the most simple and are used in prediction by training input data to obtain the desired output. The basic architecture of feed-forward networks with multi-layer perceptron is as shown in the Figure. The first layer is called the input layer, and the last layer is the output layer. The intermediate layer is called hidden layer and it can be more than one. The information is fed forward from the input layer to output layer through the hidden layers in a simple feed-forward neural network model. Thus, in the back propagation neural networks, the output value is compared to the desired value and the difference is back propagated through the network. The back propagation algorithm adjusts the weights of the neural network such that the output of the network matches the desired output. This cycle is repeated until the desired value is obtained with minimum root mean square error and is basically called training the neural network (Raymond, 1998).

1.2 Burr formation

A burr is a body created on a workpiece surface during the manufacturing of a workpiece, which extends over the intended and actual workpiece surface and has a slight volume in comparison with the workpiece, undesired, but to some extent, unavoidable. The presence of burrs on the edges of parts after machining, which may bring about a number of problems, turns deburring into a necessary part of the production process.

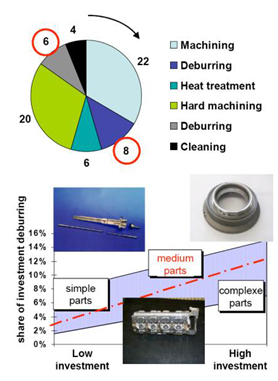

Burr removal is a non-value added process and might represent as much as 30 percent of the cost of finished parts (shown fig.1) (Berger, 2002). As deburring is non-productive and costly finishing process, it should be minimized or avoided. Any material leading to limited burr formation is therefore advantageous. Recent studies and literature have pointed out tremendous issues related to burr formation and deburring operations, including:

- Small finger injuries for assembly workers;

- Source of debris (bits of burrs) during operation, thereby reducing the life time of the machined part;

- Changing parts resistance and reduction of tool life and efficiency;

- Presentation of hazard in handling of machined parts, which can interface with subsequent assembly operations;

- Burrs that are adhered to the work part may become loose during operation, and consequently cause difficulties and damage.

Figure 1. Investment in deburring systems as a function of part complexity in manufacturing [4]

2. BACKGROUND LITERATURE

A lot of research has been conducted using neural networks in the field of machining. However, very few studies have used neural networks to predict burr height. The review of past studies carried out in drilling using neural networks is described below: Sudhakaran (1999) proposed a neural network model to identify the effect of drill geometry, specifically lip height and point angle on burr height in the drilling of aluminum 2024-T3. Feed, lip height and point angle were inputs to the model with output being burr height. The best architecture was 4-6-4 and showed good consensus with the experimental result. It was noted that burr height increases with the increase in lip height irrespective of any point angle. Sokolowski et al. (1994) proposed a neural network model to predict the burr height by considering the effect of cutting velocity, feed, depth of cut, work piece material and exit angle on burr formation. A feed forward back propagation neural network was used with a structure of 5-10-3. The output was classified into three types of burr, namely small medium and large based on the height of the burr. The developed model successfully predicted the burr height in face milling. It was also evident that neural network could act as a universal tool to model burr formation and it would also be very important from practical application standpoint because of their relative use of small data sets. Hambli (2002) developed a neural network model to predict burr height in blanking process. The input to the feed forward neural network model was tool die clearance and punch–die clearance and wear state of the tool and the corresponding output was burr height. The model showed good agreement with the experimental results with an error of less than 0.1% for any point. Karri (1999) predicted thrust and torque in drilling operations using neural networks. Eight inputs were considered and the result showed an average percentage deviation of less than 2% at the testing stage. Both thrust and torque were predicted to targeted accuracy with the help of neural networks, which was very difficult to achieve using conventional mechanics of cutting approach for prediction of thrust and torque. Sanjay and Jyothi (2006) proposed a back propagation neural network model to predict surface roughness in drilling. Drill diameter, feed, speed and machine time were used as input to ANN model. Further neural network model was more consistent for different combinations of speed and feed compared to mathematical model developed to predict surface roughness. Singh et al. (2006) developed a neural network model to predict flank wear. Various process parameters, such as speed, feed, thrust force, torque force, and drill diameter were considered as inputs and the corresponding maximum flank wear was measured. The network parameters, such as momentum coefficient, number of hidden layers, and learning coefficient were determined on trial and error. The best network architecture was considered to be 5-4-1, depending on the mean square error. Out of 49 data values, 34 were used for training the network and 15 were used for testing. The output showed good agreement with the experimental results. Therefore, neural network was considered as an important tool for prediction of drill wear. Dini (2003) developed a neural networks model to predict delamination in drilling of glass fiber reinforced plastic (GFRP). The delamination was measured at both entry and exit sides of the tool. Peel–up and push-out damage were measured at entry and exit side respectively as a function of feed rate, tool size and cutting forces. Two types of neural network model were developed to analyze and predict the delamination. The Use of the first network delamination was categorized into 4 groups, namely no damage, and low, medium and high damage, while the second network was used to predict the damage. The developed model showed very good agreement with the experimental results. Mahfouz (2001) proposed a neural network model to monitor tool wear. Vibrations and acoustic emissions were measured for 0.5 diameter HSS twist drills. Based on the experimental results, wear was classified into four types of categories. The wears were classified as chisel wear, rake crater, edge fracture, and corner wear. This information was fed into the neural network. The network correctly identified the chisel and corner wear up to 80% accuracy and edge and crater wear to around 70% accuracy. Chao and Hwang (1997) proposed a neural network model for the prediction of cutting tool life. Experiments were conducted to collect tool life data on lathe for turning operation. Each experiment is performed until a flank wear reaches a maximum of 0.7mm. The tool life is obtained by summing up the total cutting time. The results of this experiment were used in the development of a neural network model. The results were then compared against backward stepwise regression model and the artificial neural network model made the most accurate prediction. Karri et al. (2002) proposed a three layer neural network model to determine the internal surface roughness in drilling. Three types of neural network model were developed and the one that had the lowest RMS error was selected for prediction. The input to the model was frequency, speed, thrust, feed, tool type, diameter, and torque. The experiments were tested for 15 different conditions and out of which 12 exhibited an error of less than ± 0.7µm, showing considerable prediction capability.

3. MOTIVATION OF THE PRESENT WORK

3.1 Methodology

The orthogonal array forms the basis for the experimental analysis in the Taguchi method. The selection of orthogonal array is concerned with the total degree of freedom of process parameters. Total degree of freedom (DOF) associated with five parameters is equal to 10 (5X2). The degree of freedom for the orthogonal array should be greater than or, at least, equal to that of the process parameters. There by, a L27 orthogonal array having degree of freedom equal to (27-1) 26 has been considered, which is used to optimize the drilling parameters for burr size, thrust force, surface roughness, and roundness error using S/N ratio and ANOVA for machining of Al 2014 alloy. By means of the taguchi techniques, industries are able to greatly reduce the product development cycle time for design and production, thus reducing costs and increasing profit. Moreover, the neural network (NN) technique has been applied to compare the predicted values with the experimental values and compare the error between the experimental values. Finally, a confirmation test has been carried out to compare the predicted values with the experimental values, and confirm its effectiveness in the analysis of the measured responses.

3.2 Schematic Machining

In this study, the experiments were carried out on a Radial drilling machine (Make: Siddapura Machine Tools, Gujarat, INDIA) to perform different size holes on Al 2014 alloy work piece (300x50x10mm) by altering the point and clearance angles on standard HSS twist drill bits and maintaining constant helix angle of 30 degrees. Furthermore, the speed (rpm), feed rate (mm/rev), and drill diameter (mm) are varied.

3.2.1 Measuring Apparatus

The burr size (thickness and height) is measured by tool maker’s microscope and digital profile projector. During the drilling operation performed on material, thrust force was measured by kistler dynamometer.

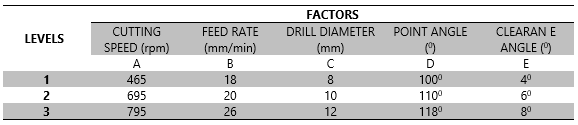

Table 1. Experimental Planning as per Taguchi Method

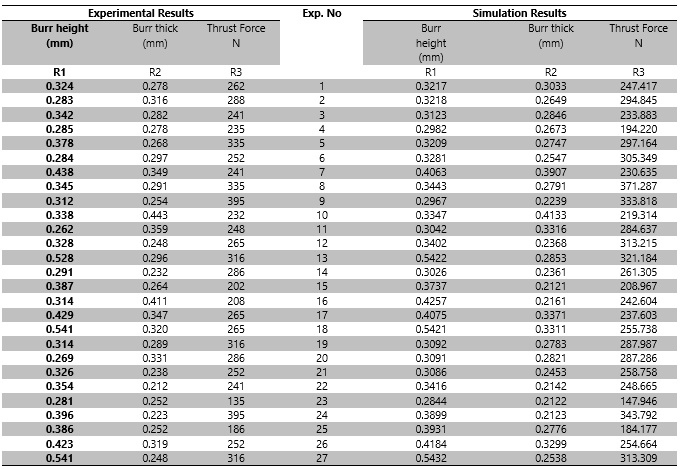

Table 2. Comparison of Experimental Results vs Neural Network Results

4. RESULTS AND DISCUSSIONS

4.1 Experimental results

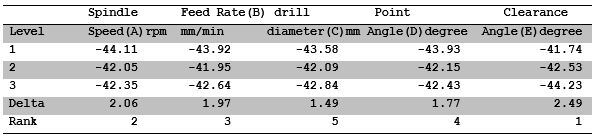

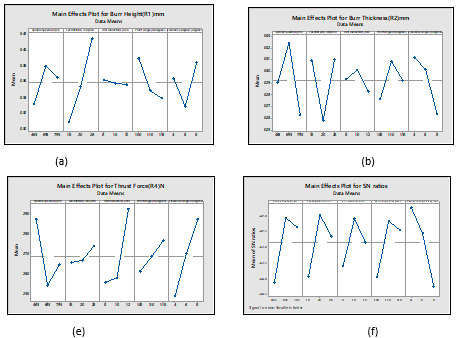

From main effects plot of S/N ratio for, the optimum parameters combination of all responses are A2B3C5D4E1, corresponding to the largest values of S/N ratio for all control parameters. From Table 3, it is observed that the clearance angle has more influence out of all parameters; feed rate has moderate influence; and cutting speed has less influence on all multi responses. For confirmation of significance of input parameters the analysis of variance is determined. The effects of input parameters versus output response graphs are drawn and the individual effects of input factors are analyzed. These factors are discussed in conclusions chapter. Finally, the interaction of individual factors over outputs found through the graphs obtained by design software was known.

Table 3. Response Table for Signal to Noise Ratios Smaller is better

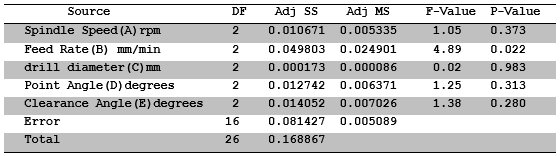

Table 4. Analysis of Variance (Burr height)

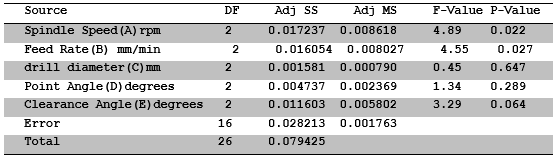

Table 5. Analysis of Variance (Burr thickness)

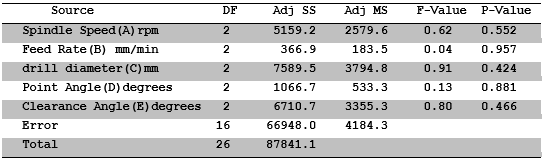

Table 6. Analysis of Variance (Thrust Force)

Figure 2. Main effects plots for responses (a, b, c, d, e) and s/n ratios (f)

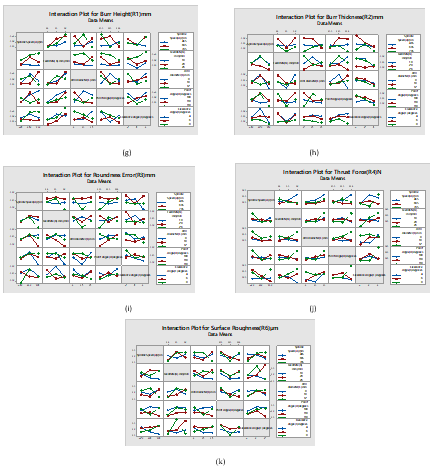

Figure 3. Interaction plot for output responses (g, h, i, j, k)

4.2 Neural network results

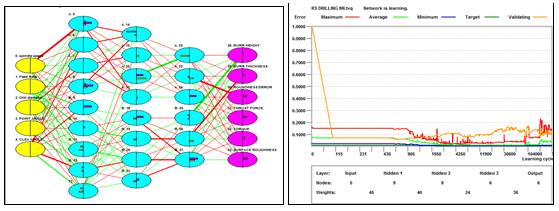

Artificial neural systems are physical cellular systems that acquire store and utilize experimental information. Powerful learning algorithm and self-organizing rule allow ANN to self-adapt according to the requirements in a continually varying environment (adaptability property). The ANN architecture is a multilayer, feed forward back propagation architecture. Multilayer perception (MLP) has an input layer, output layer, and hidden layer. The input vector is an incident on the input layer and then on the hidden layer and, subsequently, on the final layer/output layer via weighted connections. A neural network is a machine that is designed to model the way in which the brain performs a particular task or function of interest. To achieve good performance, they employ a massive interconnection of machine that can be defined as a neural network, as it is a massively parallel distributed processor made up of simple processing units, which has a natural propensity for storing experimental knowledge and making it available for use.

Figure 4. Feed Forward Neural Network block diagram and result

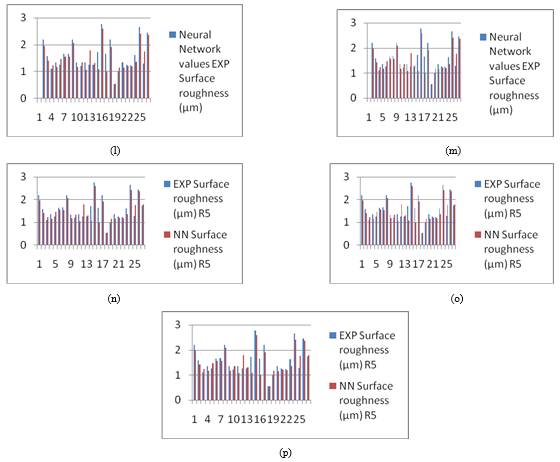

Figure 5. Validation of experimental results with neural network

The experimental observations were incorporated into the NN model. A feed forward neural network was developed to predict all outputs. Predicted and experimental values of all responses are depicted in table 2.

5. CONCLUSIONS

The machining characteristics of Al2014 alloy have been studied. The primary machining characteristics, such as drill thrust, burr size, surface quality, and circularity deviation were studied. The results obtained from the experiments are the following.

- From S/N Ratio response graph, the combination of parameters having the values of A2B3C5D4E1 obtained for input parameters in an order.

- From S/N Ratio response table, clearance angle is the most influencing factor on burr size, during drilling of Al2014 alloy.

- From the results, ANOVA for feed rate is the most significant factor for almost all responses.

- From results of NN, it is concluded that the experiment No. 15 obtained relatively more errors than the remaining. The deviation between the experimental values and the prediction values are found in the range of 3 to 4%. Finally, it is concluded that by increasing the number of nodes the computational cost increases and the error decreases. Good agreement was shown between the predictive model results and the experimental measurements.

REFERENCES

Aurich, J. C. et al. (2009), “Burrs-Analysis, control and removal”, in: CIRP Annals-Manufacturing Technology, Vol. 58, No. 2, pp. 519-42.

Berger, K. (2002), “Burr Reduction Investment - Production Costs - Burr Reduction -Prediction of Burrs.”, in: Presentation at HPC Workshop, CIRP, Paris, 23 jan., 2002.

Chao, P.Y.; Hwang, Y. D. (1997), “An Improved Neural Network Model for the Prediction of Cutting Life”, Journal of Intelligence Manufacturing, Vol. 8, No. 2, pp. 107-15.

Dini, G. (2003), “Online Prediction of Delamination in Drilling of GFRP using Neural Network Approach”, Journal of Machining Science and Technology, Vol. 7, No. 3, pp. 295-314.

Gillespie, L. (1999), Deburring and edge finishing handbook, Society of Manufacturing Engineers (SME), Dearborn, MI, USA.

Hambli, R. (2002), “Prediction of Burr Height Formation in Blanking Processes using Neural Networks”, International Journal of Mechanical Sciences, Vol. 44, pp. 2089-2102.

Karri, V. (1999), “Thrust and Torque Predictions in Drilling Operations using Neural Networks”, Advanced Manufacturing Process, Systems and Technologies, pp. 257-66.

Karri, V.; Kiatcharoenpol, T. (2002), “Prediction of Internal Surface Roughness in Drilling using Three Feed Forward Neural Networks”, in: 9th International Conference on Neural Information Processing, 2002.

Mahafouz, A. (2001), “Artificial Neural Networks for Tool Condition Monitoring in Drilling”, Journal of Smart Engineering System Design, Neural Networks, Fuzzy Logic, Evolutionary Programming, Data Mining and Complex Systems, pp. 521-6.

Raymond, S. (1998), Optimal Control of Nonlinear Systems with Neural Networks Backpropagation, PhD Dissertation, Department of Electrical Engineering, Stanford University, Stanford, CA.

Sanjay, C.; Jyothi, C. (2006), “The Study of Surface Roughness in Drilling using Neural Networks and Mathematical Model”, The International Journal of Advanced Manufacturing Technology, Vol. 29, No. 9-10, pp. 846-52.

Singh, A. K. et al. (2006), “Predicting Drill Wear using an Artificial Neural Network,” International Journal of Advanced Manufacturing and Technology, pp. 456-62.

Sokolowski, A. et al. (1994), “Prediction of Burr Size using Neural Networks and Fuzzy Logic”, in: Japan – USA symposium on Flexible Automation, 1994.

Sudhakaran. S (1999), Effect of Drill Geometry on Burr Height in Drilling of Aluminum 2024-T3, Thesis, Wichita State University, Kansas.

Received: 14 Jan 2018

Approved: 08 May 2018

DOI: 10.14488/BJOPM.2018.v15.n2.a11

How to cite: Sreenivasulu, R., SrinivasaRao, C. (2018), “Optimization of machining parameters during Drilling by Taguchi based Design of Experiments and Validation by Neural Network”, Brazilian Journal of Operations & Production Management, Vol. 15, No. 2, pp. 249-301, available from: https://bjopm.emnuvens.com.br/bjopm/article/view/440 (access year month day).