INDUSTRY 4.0: glitter or gold? A systematic review

Gustavo Bernardi Pereira

gustavo.bernardi.pereira@gmail.com

Federal University of Paraná, Curitiba, Paraná, Brazil.

Adriana de Paula Lacerda Santos

adrianapls1@gmail.com

Federal University of Paraná, Curitiba, Paraná, Brazil.

Marcelo Gechele Cleto

mgcleto@ufpr.br

Federal University of Paraná, Curitiba, Paraná, Brazil.

ABSTRACT

Publications on the fourth industrial revolution have skyrocketed since its establishment in 2011, both in academic and non-academic channels. Even though their measurable results have been published in non-academic material, especially among industry and business reports, within the academia it is still unclear how they are shown. This study aims to review and analyse the presence of industrial results within the academic context in a systematic manner by using the Preferred Reporting Items for Systematic reviews and Meta-Analyses (PRISMA) methodology. The findings indicate an increase trend of this type of publication within the academia and further directions are suggested.

Keywords: Industry 4.0; Outcome; Results; PRISMA.

1. INTRODUCTION

The manufacturing industry context has been taking big steps towards innovative advances leading to paradigm shifts. Starting from the use of mechanisation (the so-called 1st industrial revolution in the 18th century), going through the intensive use of electrical energy (the so-called 2nd industrial revolution in the 19th century), and culminating in the widespread digitalisation (3rd industrial revolution in the 20th century) (Lasi et al., 2014).

In the early 2010s, Germany has taken the lead in what has been called “The 4th industrial revolution”. Kang et al. (2016) take this movement as a revolution and summed it up as a “collection and a paradigm of various technologies that can promote strategic innovation of the existing convergence of humans, manufacturing industry through technology, and information”. However, no universal agreement on what constitutes an “industrial revolution” has been met yet (Maynard, 2015).

Whether the recent technological advances can be taken as a revolution or not, it triggered several different innovations such as: the development of new business models, an application-pull and a technology-push in industrial practice (Lasi et al., 2014). It is relevant to emphasise that this pathway of new technologies has a sustainable engineering bias embedded within it. For instance, Siemieniuch, Sinclair et Henshaw (2015) made a collection of ‘global drivers’ (such as population demographics, food security; energy security; community security and safety) to pose a direction of thinking when deploying such actions.

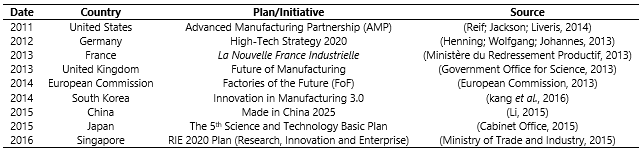

Governments and industries worldwide, aware of this trend, have been taking actions to benefit from what this set of advances can provide. Table 1 shows a list of programs by country (Liao et al., 2017).

Table 1. Initiatives by country

Source: Compiled from Liao et al. (2017)

Even though many countries have been joining efforts towards this “revolution”, the academia/industry bonding is still hard to stablish. In recent years, there has been an increase in publication on this topic; however, the state of knowledge is still relatively fragmented and tentative (Perkmann et al., 2013). One possible explanation for why such framework exists is the challenge in linking tangible and intangible inputs and outputs and capturing their relationship and value. This relationship is especially intractable when one tries to link intangible inputs (knowledge and skills) with tangible outputs (money or another measurable ROI) (Carayannis et al., 2014). This lack of systematisation hinders both research and cross-sectional studies.

Because of this weak link between the academia and the industry, the tangible results coming from the Industry 4.0 might not be placed in a systematic way among indexed databases. Looking at this context as well as the different technologies that they encompass a question arises: Within the academic database SCOPUS, what is the current status of the measurable results from the industry?

Therefore, in order to provide an appropriate answer to the stated research question, the objective of this paper is to review and analyse the presence of industrial results within the academic context in a systematic manner.

The rest of this paper is organised as follows. Section 2 presents the fundamental review principles and the systematic literature review method. Section 3 illustrates the obtained results via charts and tables. Section 4 contains the discussion of the findings, aiming to answer the research question. Section 5 concludes this paper and suggests next steps.

2. PRINCIPLES AND METHODS

A literature search of internet-based bibliographic databases was completed identifying research that had looked at tangible outcomes within the possible uses of Industry 4.0.

The search was conducted using the Scopus database. All searches were limited to the following conditions:

-

Document type: Academic article

-

Language: English

-

Year: From 2011 to 2017

In order to define the search terms, three post-graduation researchers on the topic discussed and reached a consensus . Then, the terms were tested in the databases to check whether they would fit the purpose. The final search was made by using the following terms: “Industry 4.0” AND (outcome OR result).

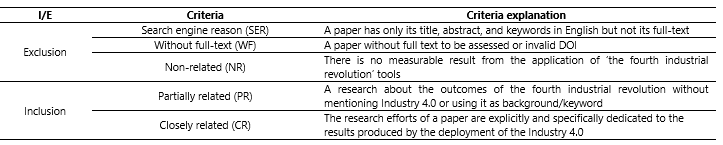

In order to reduce the subjectivity when analysing the selected papers, two fundamental review principles were defined: • Explicit inclusion and exclusion criteria: As shown in Table 2, there are five outlined criteria for including or excluding collected papers, as well as their subsets.

• Reducing subjective judgement: Each paper with unclear link between Industry 4.0 and its outcomes should be reviewed by a second examiner (researcher with enough knowledge in the area and able to discuss a better placing within the categories from Table 2.

Table 2. Inclusion and exclusion criteria and their explanations.

Source: The authors’ own (2017)

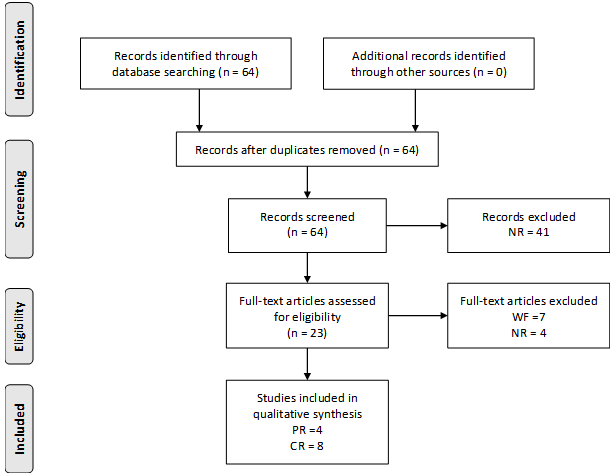

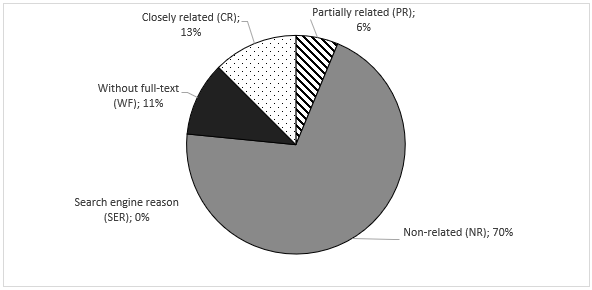

The search was carried out using the guidelines of PRISMA, which stands for Preferred Reporting Items for Systematic reviews and Meta-Analyses (Moher et al., 2009). This methodology was developed based on the definitions used by the Cochrane Collaboration (The Cochrane Collaboration, 2011), a global healthcare network focused on the way health decisions are made. The main ideas embedded in PRISMA are the iterative process and the efforts towards the reduction of assessment bias. The PRISMA framework is presented in Figure 1 and a simplified pie chart of the classification is shown in Figure 2.

Figure 1. The PRISMA flow chart that reports the different phases of the systematic literature review

Source: The authors’ own (2017)

Figure 2. Proportion of papers in each category

Source: The authors’ own (2017)

2.1 PAPER COLLECTION

The systematic search used SCOPUS as database to collect academic research that (1) were published online before the beginning of September of 2017; (2) contained at least one of the identified terms in either the abstract, title and keywords; (3) were published in academic journals; (4) were written in English.

The first screening process was carried out to exclude articles where their abstract did not contain measurable results coming from the application of ‘the fourth industrial revolution’ tools (NR). Then, all papers that passed the initial screening process had their full texts downloaded and analysed in order to exclude papers where there was no access to their full texts (WF). Some papers could not provide a clear judgement from the abstract screening and were fully read to be categorised according to whether the article has no application of any measurable result from the use of Industry 4.0 tools (NR); whether the research talks about the outcomes of the fourth industrial revolution without mentioning Industry 4.0 or using it as background/keyword (PR); and whether the research efforts of a paper are explicitly and specifically dedicated to the results produced by the deployment of the Industry 4.0 (CR).

3. RESULTS

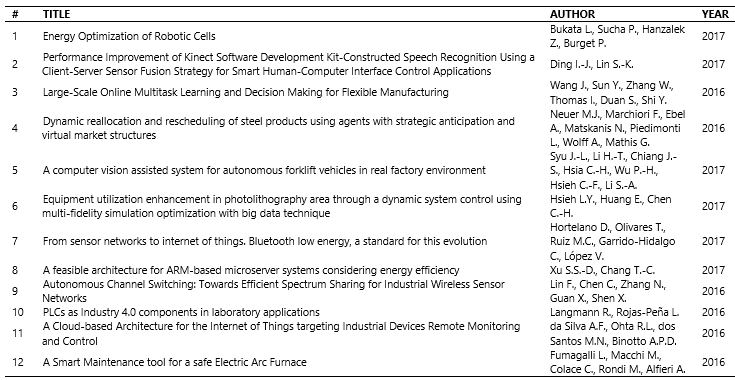

According to the fifth inclusion and exclusion criteria presented in Table 2, the number of papers in the last stage of the PRISMA flow chart (Figure 1) accounted for 12 papers out of 64 that were used for the qualitative/quantitative analysis. These papers are listed in Table 3.

Table 3. Selected papers

Source: The authors’ own (2017)

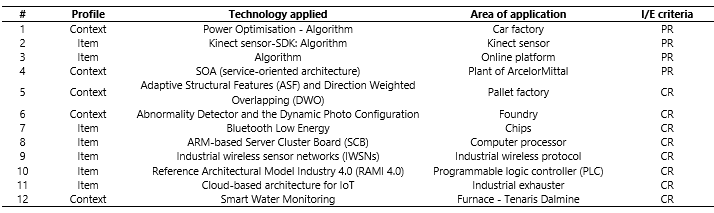

The applications presented in the papers from Table 3 were clustered according to their profile: related to the context or related to a specific item. General information about the technology applied by the author as well as the area and the paper classification according to the inclusion and exclusion criteria were also listed. The result is shown in Table 4.

Table 4. Classification of the selected papers

Source: The authors’ own (2017)

4. DISCUSSION

The abstract screening process was performed looking for values or indicators that could suggest the presence of measurable results of the research within the full text. During the screening process, several words or expressions were found not to have a strong link with measurable results when taken by their own, such as: “potential”, “feasibility”, “can lead the way for the development”, “theoretical simulation”, and “promising”. All these expressions were used either as indicators of possible uses or results obtained into a simulated environment.

The selected papers (those classified as Partially related or Closed related) represent 19% of the total. It is curious to note how recent they are; all of them were published within two years of the research date (2016-2017). This might indicate a more advanced stage in the Industry 4.0 maturation process, where there are enough studies with tangible results being published. It is important to stress that these results are among non-indexed papers, what could be seen as a research limitation.

Regarding the profile of the selected articles, they are almost evenly split between context (5 papers)/item (7 papers) application. Such division brings to light the evolution profile present in the algorithms/sensors and the joint efforts to apply them in an industrial context. It is also possible to be understood as the conjoint development of both tools and applications, instead of a division in two phases: developing tools and then applying them to a context. Another alternative is to take this process as a cycle, where the tools are tested in real life and then improved on demand.

Among the algorithms shown by the papers, there is a prevalence of the operational research (usually Mixed Integer Linear Programming) as optimisation tool. Mostly to improve an energy grid or reduce the power consumption of a specific device.

Moving back to the overall results, the low percentage of academic research that present measurable results might have two possible interpretations (stated by the light of this paper’s proposal):

• As the “Industry 4.0” is a trend term, many papers that have their main topic within the electronics or computing fields are using the term to suit the stream. Such practice ends up jeopardising the use of “Industry 4.0” as search string, as the filtering process turns into a harder task.

• Another possible reason why such low percentage of the results was obtained is the lack of standardisation about the topic. This idea goes along with the first topic; however, the difference lays on the publication profile, that does not focuses on the results that were already provided. Instead, the authors emphasise the possible applications or results coming from simulation into a controlled environment.

On the other hand, it is possible to exist published papers that are partially/closely related to the topic approached in the present study that do not identify themselves as being part of the Industry 4.0 movement.

5 CONCLUSION

The purpose of this article is to review and analyse the academic presence of measurable outcomes of the fourth industrial revolution in a systematic manner. This review provided support to identify the profile of results presented in academic articles within the Industry 4.0 context as well as to explore possible explanations for the findings.

The study was conducted based on a research question that could be answered to the extent of its limitations (mainly the search string used by the authors). However, as stated by the discussion’s last paragraph, it is possible that some measurable applications of Industry 4.0 tools have been suppressed by the lack of consensus among academia and practitioners.

REFERENCES

Cabinet Office (2015), “Report on The 5 th Science and Technology Basic Plan. [s.l: s.n.]”, available from: http://www8.cao.go.jp/cstp/kihonkeikaku/5basicplan_en.pdf (acces on 2017 Sep 6).

Carayannis, E. et al. (2014), “Managing the intellectual capital within government-university-industry R&D partnerships: A framework for the engineering research centers”, Journal of Intellectual Capital, Vol. 15, No. 4, pp. 611–30.

European Commission (2013), “Factories of the Future PPP: Towards Competitive EU Manufacturing European Commission [s.l: s.n.]”, available from: http://ec.europa.eu/research/press/2013/pdf/ppp/fof_factsheet.pdf (access on 2017 Sep 6).

Government Office For Science (2013), “The Future of Manufacturing: A new era of opportinity and challenge for the UKForesight. [s.l: s.n.]”, available from: http://www.bis.gov.uk/foresight (access on 2017 Sep 6).

Henning, K. et al. (2014),”Recommendations for implementing the strategic initiative Industrie 4.0 Final report of the Industrie 4.0 WG. [s.l: s.n.]”, available from: http://www.acatech.de/fileadmin/user_upload/Baumstruktur_nach_Website/Acatech/root/de/Material_fuer_Sonderseiten/Industrie_4.0/Final_report__Industrie_4.0_accessible.pdf (access on 2017 Sep 6).

Kang, H. S. et al. (2016), “Smart manufacturing: Past research, present findings, and future directions”, International Journal of Precision Engineering and Manufacturing - Green Technology, Vol. 3, No. 1, pp. 111–28.

Lasi, H. et al. (2014), “Industry 4.0”, Business and Information Systems Engineering, Vol. 6, No. 4, pp. 239–42.

Li, K. (2015), “Made in China 2025”, available from: http://www.gov.cn/zhengce/content/2015-05/19/content_9784.htm (access on 2017 Sep 6).

Liao, Y. et al. (2017), “Past Present and future of Industry 4.0 - a systematic literature review and research agenda proposal”, International Journal of Production Research, Vol. 55, No. 12, pp. 3609–29.

Maynard, A. D. (2015), “Navigating the fourth industrial revolution”, Nature Nanotechnology, Vol. 10, No. 12, pp. 1005–06.

Ministère Du Redressement Productif (2013), “The New Face of Industry In France. [s.l: s.n.]”, available from: http://www.entreprises.gouv.fr/files/files/directions_services/secteurs-professionnels/industrie/nfi/NFI-anglais.pdf (access on 2017 Sep 6).

Ministry of Trade and Industry (2015), “Research, Innovation and Enterprise (RIE) 2015 Plan. [s.l: s.n.]”, available from: https://www.mti.gov.sg/ResearchRoom/Documents/app.mti.gov.sg/data/pages/885/doc/RIE2015.pdf (access on 2017 Sep 6).

Moher, D. et al. (2009), “The Prisma Group - Preferred reporting items for systematic reviews and meta-analyses (PRISMA) statement”, Journal of Clinical Epidemiology, Vol. 62, No. 2009, p. 1006–12.

Perkmann, M. et al. (2013), “Academic engagement and commercialisation : A review of the literature on university – industry relations”, Research Policy, Vol. 42, No. 2, pp. 423–42.

Reif, R. et al. (2014), “Report To The President Accelerating U.S. Advanced ManufacturingExecutive Office of the president of the United States. [s.l: s.n.]”, available from: https://www.whitehouse.gov/sites/default/files/microsites/ostp/PCAST/amp20_report_final.pdf (access on 2017 Sep 6).

Siemieniuch, C. E. et al. (2015), “Global drivers, sustainable manufacturing and systems ergonomics”, Applied Ergonomics, Vol. 51, pp. 104–19.

The Cochrane Collaboration (2011), “Cochrane Handbook for Systematic Reviews of Interventions. [s.l: s.n.]”, available from: http://handbook-5-1.cochrane.org/ (access on 2017 Nov 16).

Received: 09 Sep 2017

Approved: 08 May 2018

DOI: 10.14488/BJOPM.2018.v15.n2.a7

How to cite: Pereira, G. B., Santos, A. P. L., Cleto, M. G. (2018), “INDUSTRY 4.0: glitter or gold? A systematic review”, Brazilian Journal of Operations & Production Management, Vol. 15, No. 2, pp. 247-253, available from: https://bjopm.emnuvens.com.br/bjopm/article/view/411 (access year month day).