An ergonomics solution in the footwear industry: the footwear unmold

Francisco Soares Másculo

Paraíba Federal University

Abstract

The aim of this work was to analyze the influence of the implementation of ergonomic measures in the work conditions of the cemented assembly section in the unmold activity in a shoe industry located in the state of Paraíba. To do so, a comparative analysis related to the ergonomic improvements previously implanted in the workstations of the company was carried out, looking to verify whether the application of those measures had influenced or not the work conditions in the assembly section mentioned. Historically, that type of industry doesn't have a culture of Prevention of Accidents and Ergonomics in its practices. Consequently, the elevation of the number of acquired diseases related to the work in that section was observed. As methodological procedures, interviews were accomplished with workers of the Assembly Section of the company, aiming to make the measurement of the work conditions, starting from the application of the methodology Situation, Problem and Improvement (SPI) and of the method Occupational Repetitive Action (OCRA), Gravity, Urgency and Tendency (GUT) and the diagram of painful areas of Corlett et Manenica (1980). As a result, improvements of the work conditions were evidenced with the elimination of most non-ergonomic conditions in the activity, besides making possible larger motivation and better life quality to the employees of the studied section.

Keywords: Work Conditions; Ergonomics; Shoe Industry.

1. Introduction

The shoe industry in the last years presented vertiginous growth in the Northeast area of Brazil and it stands out for the great variety of activities involved in its productive process (Azevedo, 2002). The productive segments are constituted of fine fashion, sporting, rubber sandal, leather footwear and injected. Historically, that industry type doesn't have, in its practices, a prevention culture linked to the ergonomic subjects in its work places, which led to a larger index of diseases acquired by the workers (Renner et Bühler, 2006). Some of the causes of that result are due to the complexity of the productive process, purely characterized by manufacturing activities, whose duration cycles are short and, therefore, very repetitive. Another factor is the limited possibility of automation of the production in some processes in the shoe industry (Hartkopf, 2001; Vanin, 2007). The activities carried out repeatedly and which do not demand reasoning become monotonous and senseless. The Taylorist/Fordist model, adopted in most footwear industries, assumes that workers should be set in the work station, requesting, for that, a specialist. The accomplishment of an exclusive and senseless activity tends to unchain irritability, indifference, larger sensibility to heat, cold, hunger and bad posture (IIDA, 2010, p. 357). Guimarães (2012, p. 949) has indicated that the company should provide several abilities to the work groups, making possible the creation of value both for the professionals and for the company, because the enlargement and the enrichment of the work, besides breaking paradigms, are forms of reducing the dissatisfaction, monotony, repetitiveness, mistakes and diseases at work. The characteristics of the adopted system have contributed to increase even more the statistics of acquired diseases due to the bad ergonomic conditions of such work stations. Consequently, the inadequate work conditions to which the workers are submitted and the increase of the pathologies due to ergonomic factors became focus of the fiscalization institutions, such as the Department of Labor and Employment (DLE) and the Public Prosecution Service of the Work. It can be affirmed that, in a certain way, that this issue has pressed the companies to analyze their positions regarding the environmental conditions and the quality of life at work, aimed to adapt them to the workers' capabilities/necessities, thus attending to the labor legislation and seeking to reduce social costs. A lot of organizations adopted good ergonomic practices in their industrial parks through the implantation of ergonomic projects, and it is increasingly larger the number of ergonomic studies developed in the shoe area (Renner, 2002).

2. The postures adopted in the assemblies of shoes

In the shoe sector, the work in most of the positions was made with the worker in the sitting position. However, from the 1990's on, the industries in the south eliminated most of the seats because these (straw chairs) did not meet NR-17 standards, Brazilian ergonomic norm (Brasil, 2007), which describes that the "seats should be ergonomic", with wheels, seat and backrest padded, and adjustments of height of the seat and backrest. With the elimination of the chairs, more space was generated in the production line; this way, the work was usually performed with the worker in a standing position in most of the companies; thus, it ended up being the pattern adopted in the whole country (Renner, 2002). The standing position allows corporal mobility, facilitating the dynamic use of arms, legs and trunk. The arms and legs can be used to reach the controls of the machines (Iida, 2010, p. 166). However, the still standing position it is highly tiring, due to the demand of the musculature to maintain the position. The body remains oscillating, demanding frequent positioning; thus, the work accomplishment is hindered. A workstation that best assists users' needs is that which allows the alternation of the postures in standing and sitting positions (Másculo, 2011).

3. Data collection

Data collection was concentrated on the operators of the shoe unmold activities and assembly cells of the cemented sector of the industry, using the presuppositions of the method Situation, Problem and Improvement (SPI) (Vidal, 2011).

3.1 The method SPI - situation, problem and improvement

The SPI tool enables an ergonomic action in a short space of time, due to the quick summarizing of some results and the setting up of a matrix of characteristics (Vidal, 2011). Through SPM, some methods and tools were used, such as GUT (Gravity, Urgency and Tendency), the Diagram of Corlett et Manenica, the Method OCRA, the normative framing in relation to the NR-17 standards, the impacts of the existent problems in the work place and the Summation of the Criticality Index - SCI.

The production process flow of the assembly cell of cemented

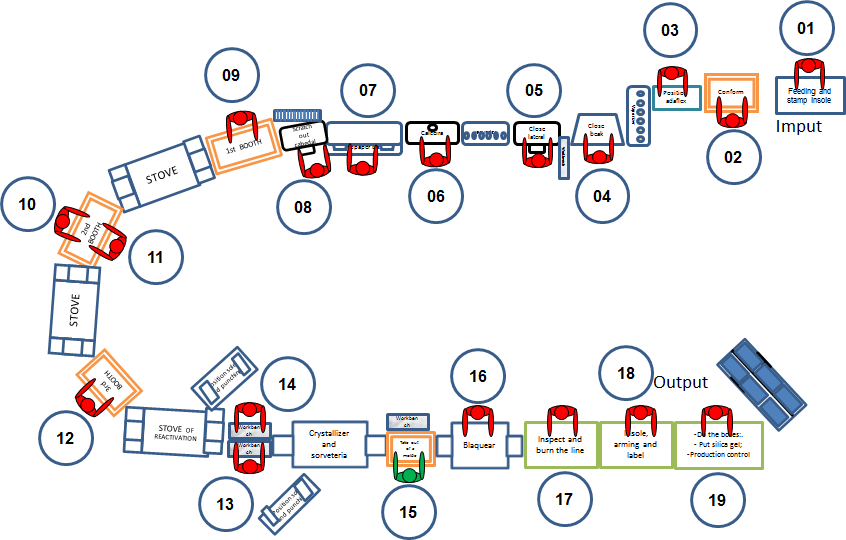

The flow charter of the activities accomplished in the assembly cells in U-shape (Figure 1) seeks to provide the visualization of the flow of the productive system, of the distribution of the work stations and of the sequences along the production line. The layout is flexible, making possible the change of equipment and positions to assist the alterations of models, in agreement with the solicitations of PPC (Production Programming and Control) (Iida, 2010).

Figure 1. Schematic draw of a production cell and location of the work stations of the cemented assembly sector, where the work station selected for this study was the number 15 (author's elaboration, 2013).

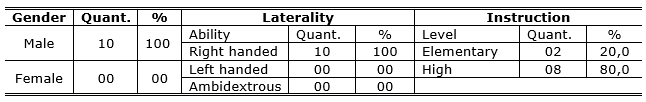

Workers profile in the unmold activity

The workers unmold activity profile was collected and it can be seen in Table 1 below.

Table 1. The workers interviewees of the unmold activity profile (author's elaboration, 2013)

Analyzing the workers' profile of the unmold activity (Table 1), 100% of them are male. Sometimes, when the workers that use the unmold machines need to assist their physiologic needs, they can be substituted by the women in the operation. With regard to the workers' laterality, the predominance is of right-handed individuals. As for the instruction degree, 20% have the elementary school and 80% complete high school. The workers of the cells workstation were not the same ones for the whole research.

Location of the workstation in the cell and the number of workstations that were analyzed

In this universe, the sample was composed by five functions, each occupied by one worker, in which there was ergonomic intervention, with implementation of a mechanical device for unmolding the shoe, and in five workstations in assembly cells of the cemented section, where a mechanical device was not still implemented for unmolding shoes.

Figure 2. Workstations, constituted by benches with pin and machine, used for unmolding shoes (own elaboration, 2013)

Figure 3. Manual unmolding.

Figure 4. Mechanical unmolding.

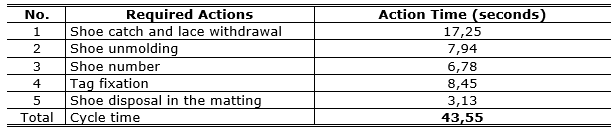

Ergonomic demands regarding time and movement of the activity accomplished manually

According to Smidele et al. (2009), the production cycle is the time interval necessary for the production of a unit of the product. The Table 2 specifies the activity accomplished mechanically that presented a cycle of 43.55 seconds:

Table 2. Descriptive chartof the actions accomplished by the superior members in the activity accomplished manually in seconds (own elaboration, 2013)

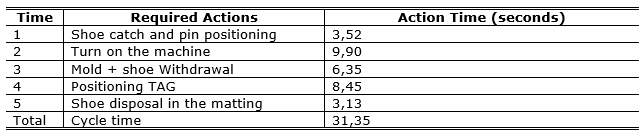

Ergonomic demands regarding times and movements of the activity accomplished mechanically

Table 3. Descriptive chart of the actions accomplished by the upper limbs in the activity accomplished mechanically, in seconds (author elaboration, 2013)

According to NR-17.6.1 (Brazilian Norm 17), the organization of the work should be adapted to the workers' psycho-physiological characteristics and the nature of the work to be executed. Reduction of the time of the cycle and of the requested actions provides improvement for the workers, with decrease in terms of lesion probability for musculoskeletal effort.

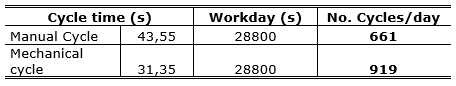

Comparative analysis of the times of cycle for the unmolding activity

There was a reduction of times in the actions 1, 2 and 3 in a total of 12.20 seconds in the cycle of the operation. The improvement of this reduction in the resulting productivity is demonstrated in the Table 4. Even with the reduction of the cycle, there was no increase in the production, and this time was used as personal pauses and better recovery of the musculature, within the work day.

Tabel 4. Comparative of the number of possible cycles by manual and mechanical methods (author’s elaboration, 2013)

That improvement is justified by the increase of the working power with the consumption of the same productive resources in terms of effective personnel (productivity of workers), for making possible an increment in the number of possible cycles during the daily work, which implies a better use of inputs and labor. Therefore, the option for inserting an automatic extraction device reduces considerably the effort performed by workers with the upper limbs. In this case, the activity cycle remains above the 30-second minimum limit for the pair, which is 31.35 seconds. The number of possible cycles during a normal day of eight hours of work could be altered from 661 to 919, an increment of approximately 39% of the capacity.

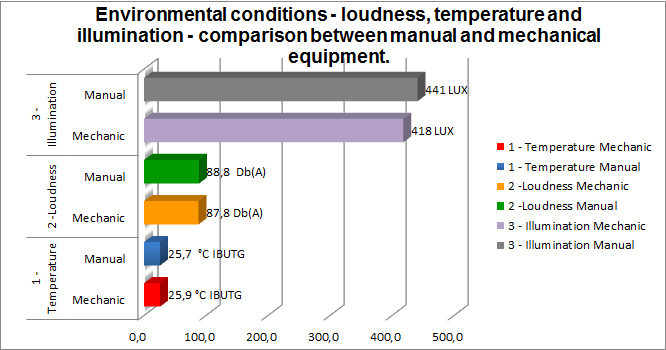

Comparative analysis of the aspects subject to the workstations' environment

The items of ergonomic demand related to the workstations were compared before and after the intervention, in what concerns the noise, temperature and illumination, as expressed in the Figure 5.

Figure 5. Environmental conditions, noise, temperature and illumination - comparative among the activities performed mechanically and manually (author’s elaboration, 2013)

The appreciation of the medium values obtained from the readings made in the workstations (Graph 1) compares the environmental conditions before and after intervention. With relationship to the heat, the variation was of 0.2 °C in IBUTG (Wet bulb globe thermometer index). With relationship to the noise, there is a medium variation of 1 dB (A). The medium reading of the illumination was above recommended in the two work conditions. As for the individual research, the workers of the unmold activity, who used the machine, informed that the thermal sensation was reduced, because it is performed without adopting high physical effort, in addition to the ventilation by fans positioned in the high line of the air-tablet, which improved the heat sensation.

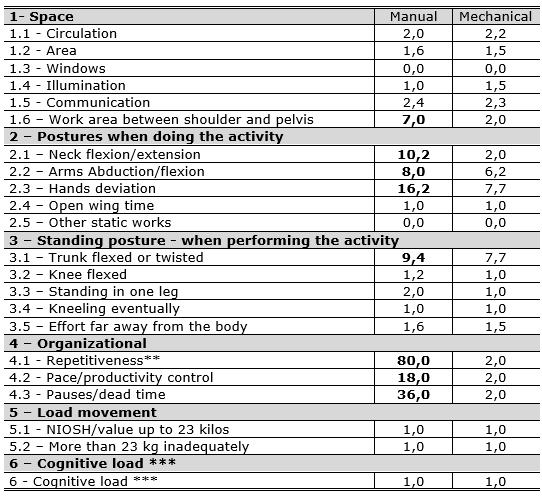

Method GUT

The appreciation of the method GUT (Gravity, Urgency and Tendency) has, as its objective, to verify why the implementation of the unmold machine caused reduction in the bad work conditions, and in which of the aspects, as perceptible in Table 5.

Table 5. Average results of the appreciation of the activity accomplished manually and mechanically in the workstations (author’s own elaboration, 2013)

Analyzing the presented results, with respect to the space in the activity performed manually, the work area between shoulder and pelvis showed an index of 7.0, while the activity mechanically carried out presented an index of 2.0. As for the assumed postures, the activity performed manually presented neck flexed/extended of 10.2 and the activity performed mechanically of 2.0. The flexion/abduction of the arms, in the activity accomplished manually, presented an index of 8.0 and the mechanically carried out presented an index of 6.2. For the deviation of the hands, in the activities manually accomplishment, 16.2, and the activities mechanically performed, 7.7. In the accomplishment of the manual activity in the standing position, trunk twisted and flexed, it was of 9.4, and in the mechanical activity carried out, 7.7. With regard to the work organization in the workstation and repetitiveness in the manual accomplishment, 80.0 and the activity mechanically performed, 2. The productivity pace/control was of 18.0 for the manual activity and 2.0 for the mechanical activity. For pause/dead time in the manual activity, it was observed 36.0 and in the activity accomplished mechanically, 2.0. With the appreciation of those results, it was verified that the organization of the workstation and the assumed postures are the factors that affect negatively the accomplishment of the manual activity.

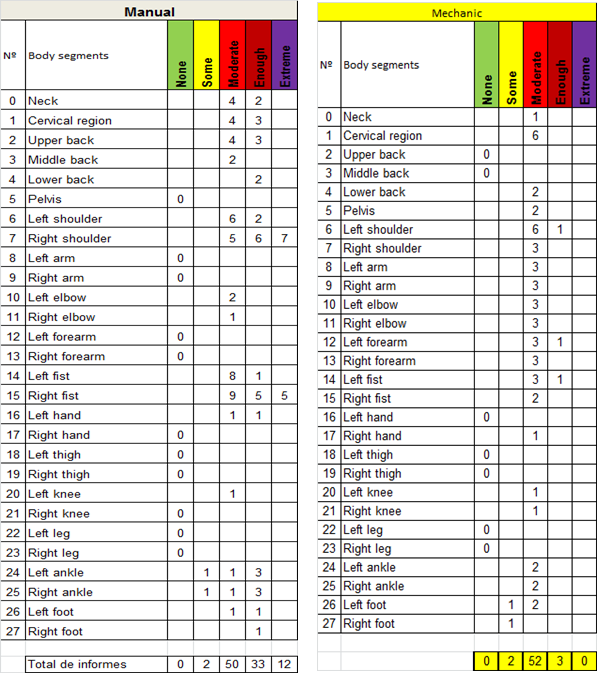

Method diagram of Corlett and Manenica

The appreciation of the results of the discomfort reports of the employees at the end of the work day, in a period of four weeks, in which, for every week, accomplished set of questions were asked to the employees on whether they felt discomfort at the end of the work shift and in which part of the body. The comparative of the summations is presented in Table 6.

Table 6. Summations of informed discomfort for the workers of the activity accomplished manually and mechanically (author’s elaboration, 2013)

Analyzing the results of the summation of the workers' answers, with respect to the discomfort at the end of the work day, the reports of Extreme discomfort were reduced from twelve (12) reports in the manual activity, for zero (0) in the mechanical activity. Regarding the information of plenty of discomfort, there was a reduction of the manual reports from thirty three (33) reports, to three (3) reports for the activity accomplished mechanically. As for the information on moderate discomfort, there was an increase of the manual activity from fifty (50) to fifty two (52) in the activity accomplished mechanically, indicating an increase in the discomfort reports. According to Iida (2010, p. 359), the reduction of the fatigue can be attributed to the implementation of good practices in the postures, reach zone and reduction of physical effort above recommended.

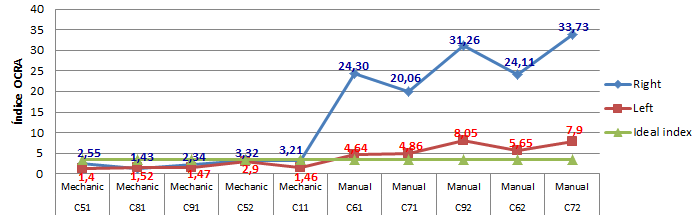

Method OCRA

The Method OCRA was used in the work positions of the manual unmold activities and the activity with use of the machine. Figure 4 refers to the results of OCRA of the right and left superior members.

Figure 6. Comparative of OCRA of the right and left superior members

Verifying the OCRA method’s results, in the activity accomplished manually, the smallest score obtained in the five analyses of the left member it was 4.64 and for the right member it was 20.06. The activity accomplished manually presents risk for the right and left superior members. In the activity performed mechanically, the largest score obtained in the five analyses in the left superior member was 2.90 and the right was 3.32; therefore, the activity accomplished mechanically presented low risk for repetitive movements in the work day. It was verified that the implementation of the unmold machine reduced or even eliminated the conditions that can lead to musculoskeletal disorders.

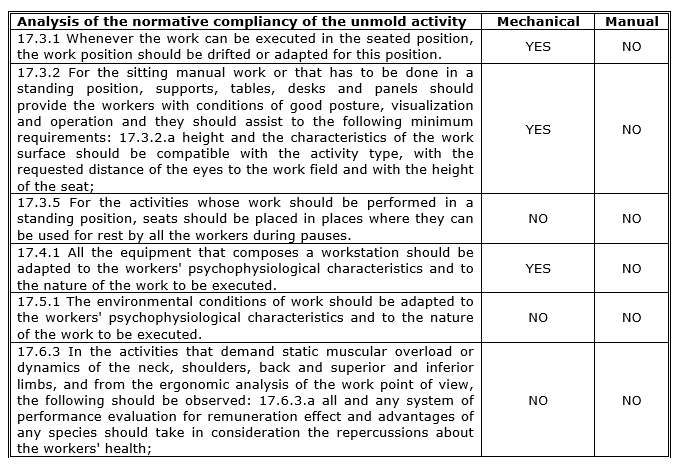

Normative compliancy to NR-17 - Brazilian Norm 17

The normative compliance is the correlation among the impacts, specifying priority root causes observed as a reference to NR-17. These were analyzed and diagnosed according to the labor legislation, according to the Table 7. The analysis of the item is accomplished according to the researcher's perception: statement YES, when the workstation attends the specified; and statement NO, when the workstation does not meet the specified.

Table 7. Normative compliancy of the activities of mechanical and manual unmold (author's elaboration, 2013)

The activity accomplished mechanically presented three impacts that can lead to workers’ discomfort, and the activity accomplished manually presents six impacts verified that can lead to workers’ discomfort.

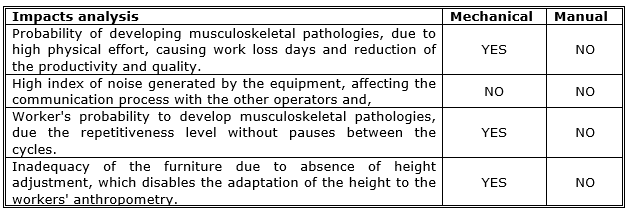

Problems present in the work place - impacts

The impacts refer to problems in the work place that harm the good course of the activity and the workers' health. In this item, the present conditions were analyzed in the workstation in agreement with the questions asked to workers, as presented in Table 8.

Table 8. Comparative of the impacts in the worker's health of the activities of mechanical and manual unmold (self-elaboration, 2013).

The activity accomplished mechanically presented an impact that can lead workers to discomfort, and the activity accomplished manually presents four impacts that can lead to the discomfort of workers. This way, the answer YES indicates that the item is accomplished in the activity. Yet, the answer NO means that the item is not assisted in the activity.

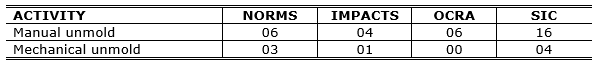

Summation of the criticality index - SCI

The result of SCI refers to the appreciations of the norms that are not met by the work conditions present in the workstations, with regard to the legislation for the accomplishment of the unmold activity manually and with machine use (Table 9).

Table 9. Comparative of SCI - summation of the criticality index of workstation (self-elaboration, 2013)

In the appreciation of the SCI data seen in Table 9, it is observed that the result of the manual unmold activity presented a score of 16; on the other hand, the unmold mechanical activity presented a score of 04, which demonstrates a reduction of 12 points, indicating activities accomplished with reduced musculoskeletal effort and tendency to Repetitive Trauma Disorders. SCI with result above 10 requests direction of immediate actions. As a way of improving the work conditions of the activity performed mechanically, it is suggested that a study of the pneumatic system of the unmold machine is carried out by the maintenance section, in order to reduce the escape of air that increases the noise of the environment. As to illumination, the evaluation of the lamp bulbs should be performed, as the change for newer bulbs that will increase the illumination and will provide compliance to the legislation. The reduction of SCI was evidenced with the workers' information about the reduction of the use of force to extract the footwear from the mold, in the appreciation of the OCRA index and of the diagram Corlett & Manenica. The unmold machine was projected with height adjustment in the machine and the fixation pin in the way that makes the appropriate posture possible for anthropometry, thus providing discomfort reduction.

4. Conclusion

The hypothesis that the manual performance of the work in the unmold activity in cemented assembly cells can lead to discomfort, inadequate posture and pain, mainly of the superior limbs, was confirmed. Starting from the analyses of the activity performed mechanically, it can be affirmed that the implemented ergonomic improvements, elimination of the physical effort of force and pressure and the inadequate postures reduced the OCRA indexes regarding the superior limbs, both left and right, for acceptable activity with relation to repetitive movements. When reducing the use of applied force and the actions requested for the accomplishment of a cycle with fewer movements, as well as with the change of the assumed postures, the work conditions were improved and the possibility of musculoskeletal discomfort was decreased; this is described as ergonomic improvements (Gomes et Manly, 2011). The worker with physical limitations of the superior limbs informed that the fatigue that was felt at the end of the day was reduced and that work was much better. The evaluation of the discomfort reports for the Diagram of Corlett and Manenica of the activity accomplished with mechanical aid did not present the occurrence of extreme discomfort in the areas of the body, as informed by the workers. As to the application of the methodology SPI, the final score for the activity accomplished manually was 16, surpassing the acceptable score, which is 10. The final score for the activity accomplished with the use of the unmold machine was 4, indicating alterations regarding the furniture of the machine with devices of height adjustment. The footwear extraction system performed in the pneumatic equipment reduced the musculoskeletal effort for an acceptable index, and the implementation of fans in the cells improved the thermal sensation in the environment. Besides, it was referred that the substitution of the benches for those with height adjustment provided adaptation conditions of the workstation to the workers' anthropometry, complying with NR-17 in terms of ergonomics. As a conclusion, the unmolding activity accomplished by means of the unmold machine and the improvements in the workstation with an ergonomic focus collaborated with lowering the risk of acquiring musculoskeletal disorders of the superior limbs, improvement in the conditions of the thermal sensation, of the satisfaction at work and the increase of productivity.

References

Azevedo, P.F. (2002), Competitividade da Cadeia de Couro e Calçados. Fórum de Competitividade da Cadeia Produtiva de Couro e Calçados. Brasília: MDIC/PENSA, 2002 (Relatório). Disponível em: http://wwwp.feb.unesp.br/renofio/producao limpa/Van/Couro/estudopensaccouroForumCompetitividadeCouroCalcado.pdf. Acesso em: 24 jul. 2012.

Brasil (2007), Ministério do Trabalho, NR-17: Ergonomia, MTE, Brasília, DF.

Guimarães L.B.M. et al. (2012), Cost-benefit analysis of a socio-technical intervention in a Brazilian footwear company, Applied Ergonomics, Vol. 43, pp. 948-957.

Hartkopf, H.H. (2001), A globalização e a indústria calçadista, Associação Brasileira de Empresas de Componentes para Couro, Calçados e Artefatos - ASSINTECAL, Novo Hamburgo, RS.

Iida, I. (2010), Ergonomia: Projeto e produção, 2. ed., Blücher, São Paulo, SP.

Másculo, F.S. (2011), “Biomecânica”, In: Másculo, F.S.; Vidal, M.C.R. (Orgs.), Ergonomia Trabalho adequado e eficiente, Elsevier, Rio de Janeiro, RJ, pp. 167-195.

Renner, J.S.; Bühler, D.C. (2006), “Ergonomia em curtume: atividade e organização do trabalho”, In: 14º Congresso Brasileiro de Ergonomia, UFPR, Curitiba (CD-ROM).

Smidele, C.D. et al. (2009), “A busca da eficiência e a importância do balanceamento de linhas de produção”, In: 17º Encontro Nacional de Engenharia de Produção, Gramado, RS. Abrepo, Rio de Janeiro, RJ.

Vanin, J.A. (2007), “Estratégias de Competição de Indústrias Calçadistas Brasileiras: Um Estudo de Caso”, In: 3º Encontro de Estudos em Estratégias, ANPAD, São Paulo, SP.

Vidal, M.C.R. (2011), “Métodos alternativos em análise ergonômica”, In: Másculo, F.S.; Vidal, M.C.R. (Orgs.), “Ergonomia: trabalho adequado e eficiente, Elsevier, Rio de Janeiro, RJ, pp. 266-283.