Comparative analysis between challenges in a Brazilian perspective and worldwide initiatives in Advanced Manufacturing

Guilherme Mancilha

guimancilha@gmail.com

Institution, City, State, Country

Jefferson Gomes

gomes@ita.br

Institution, City, State, Country

ABSTRACT

The purpose of this paper is to analyze possible actions to overcome the challenges in the process of development Advanced Manufacturing in Brazil, based on a comparative analysis of projects developed in these subjects in other countries and a survey of research intensity on the theme. The first step is the survey of Brazil's Challenges in Advanced Manufacturing based on the results of a series of workshops conducted by the Brazilian government with experts, followed by validation and consolidation of results by confronting with a National Confederation of Industries' survey on Industry 4.0. The second brings a survey of the intensity and relevance of the research on the main aspects of the theme. The last step presents a correlation of the main challenges raised in the first step with global initiatives that work on these subjects, as well as a detailed analysis of the main challenges. The results highlight a direction for the sector from the analysis of research intensity on the themes and a matrix with 40 initiatives correlated to this challenge. From that, it is possible to conclude that the challenges can be overcome by integrating government, companies and universities into initiatives focused on the technologies needed to serve the priority sectors.

Keywords: Advanced Manufacturing; Industry 4.0.

1 INTRODUCTION

Advanced Manufacturing, a nomenclature used by some experts for the current revolution, is the joining of a family of activities that rely on the use and coordination of information, automation, computing, software, sensors and networks, and/or the use of cutting-edge materials and processes, where new methods of manufacturing of existing products are possible as well as the production of new products through new manufacturing techniques (President’s Council of Advisors on Science and Technology, 2011).

This industrial race has involved the players of the sector in the world scenario, which has invested in structured programs, in order to favor and encourage the development of the Advanced Manufacturing, maintaining and advancing its markets and position in this sector, namely:

• USA: In 2012, the National Science and Technology Council of the USA published the work titled "The National Strategic Plan for Advanced Manufacturing", which brings national planning to support research in advanced manufacturing, bringing together industries, universities and government in order to accelerate investment, direct the education model to future work, create and support public-private partnerships and map the necessary and strategic investments for the sector.

• Germany: In 2013, the German Academy of Science and Engineering (ACATECH) published the work titled "Recommendations for implementing the strategic initiative INDUSTRIE 4.0", which establishes a strategy for the country to become the main supplier of intelligent production technologies, and integrates production with other leading countries, with the aim of monitoring technologies and generating standards.

• China: In the 13th Five-Year Plan 2016-2020 (13th Five-Year Plan), the government envisions concentrating on manufacturing innovation and integration of information and manufacturing technologies, as well as encouraging the opening and relaxing of restrictions to encourage foreign investment in Advanced manufacturing in the country.

In Brazil, several challenges will arise along the new industrial revolution. The country has a closed market, bureaucracy and high investment cost - a Brazilian company spends an average of 37% more than a USA company in acquiring the same equipment - which directly affects the updating and acquisition of equipment and technologies necessary for the implantation of Advanced Manufacturing (Exame, 2014). In some sectors of the economy, such as the automotive industry, the application of national content finds great difficulty since the entire value chain is monopolized by multinationals; however, other sectors such as food, in which Brazil is a big player, the country has great opportunities.

The objective of this article is to analyze possible actions to overcome the challenges in the development process of advanced manufacturing in Brazil, pointed by experts, through a comparative analysis of several initiatives in these subjects developed in other countries and a survey of research intensity on the theme.

2 BACKGROUND

Countries such as Germany, the United States and China see a unique opportunity for economic growth in the new industrial revolution underway. To this end, they have created public policies for the development of Advanced Manufacturing, which are already beginning to present successful results [3-5].

In the United States, with the National Strategic plan for Advanced Manufacturing, the government has shown signals concerning Human Resources by investing and creating public-private partnerships (NSTC, 2012). The entire development program is led by the Manufacturing USA initiative, whose mission to convene and enable public-private partnerships focused on manufacturing innovation involving US universities to design and implement an integrated whole-of-government advanced manufacturing initiative to facilitate collaboration and information sharing across federal agencies (Manufacturing USA, 2016).

In Germany, the leading country in the manufacturing sector, ACATECH, made several recommendations for the new industrial revolution to be part of country's strategic plan. The theme today is part of the German strategic plan and several initiatives are being developed to support with the necessary technologies the priority sectors of the country (ACATECH, 2013).

In China, which is the largest producer of manufactured goods, the Advanced Manufacturing theme is one of the central themes of the Chinese government's plan titled “Made in China 2025” (PWC, 2016). The goal of the plan is to modernize the manufacturing sector of the country with advanced technologies, and for that it have already invested 150 billion dollars. The Chinese Manufacturing may dominate the sector in the future, according to Forbes magazine (FORBES, 2016).

In Brazil, the Ministry of Development, Industry and Foreign Trade (MDIC) and the Ministry of Science, Technology and Innovation (MCTI) have set up an advanced manufacturing task force with the participation of government representatives, public institutions and the private sector with the aim of elaborating the National Policy on Advanced Manufacturing. The first result of this effort points out challenges and opportunities from the perspective of Brazilian experts on advanced manufacturing (MDIC, 2016).

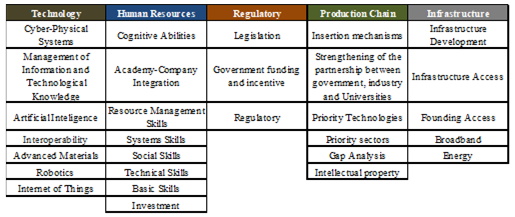

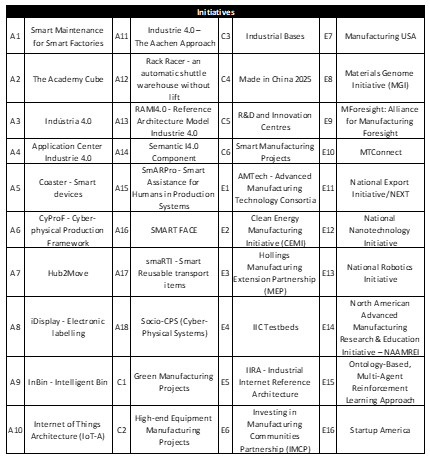

The mentioned results are present in the work entitled “Perspectivas de Especialistas brasileiros sobre a Manufatura Avançada no Brasil” (Perspectives of Brazilian Experts on Advanced Manufacturing in Brazil), in which the various subjects are divided into five themes: Technology, Human Resources, Regulation, Production Chain and Infrastructure (MDIC and MCTI, 2016). The aspects raised in the work as challenges for Brazil in the new industrial revolution are presented in Figure 1.

Another work carried out in the country by the National Confederation of Industries (CNI), which believes that the advance of Industry 4.0 in Brazil is directly related to the use of digital technologies and the greater knowledge gained by the companies, has the objective to verify the level of the national industry with respect to the knowledge and use of digital technologies (CNI, 2016).

Figure 1. List of challenges for Brazil in Advanced Manufacturing (MDIC and MCTI, 2016).

3 MATERIALS AND METHODS

The method applied in this article is divided into three stages:

• Step 1: Survey of Brazil's Challenges in Advanced Manufacturing.

• Step 2: Assessing the Intensity and Relevance of each Challenge in the world.

• Step 3: Correlation between the Brazilian challenges and worldwide initiatives.

The first stage contains a validation and consolidation of the challenges present in the work “Perspectivas de Especialistas brasileiros sobre a Manufatura Avanaçada no Brasil” (Perspectives of Brazilian Experts on Advanced Manufacturing in Brazil), a series of workshops accomplished in some state capitals, confronting with CNI’s research on the subject, generating a final listing of the challenges for the country. The second stage consists of a survey to evaluate the relevance of the challenges raised, in order to show the intensity of these aspects in the global scenario. The third stage analyzes the challenges and opportunities, comparing them with related initiatives developed in other countries.

3.1 Step 1: Survey of Brazil's Challenges in Advanced Manufacturing

Differently of the Advanced Manufacturing workshops, which counted with the participation of specialists from the country in areas related to the new industrial revolution, CNI’s Special Survey on Industry 4.0 was carried out in a general way and counted on 2,225 companies of all sizes and sectors, and on different stages of the value chain. This survey was used to map the current national industry scenario and check the challenges for the deployment of the green and yellow Industry 4.0 (CNI, 2016).

In order to validate and consolidate the Brazilian vision regarding challenges of the fourth industrial revolution, the results obtained in the workshops were confronted with CNI’s special survey. With different points of view, the two studies work in a complementary way and their results were used as support to map the challenges of Brazil in Advanced Manufacturing, the main objective of this first stage.

3.2 Step 2: Assessing the Intensity and Relevance of each Challenge in the world

The second step is to evaluate the intensity of research and relevance of each key term. In this way, the first activity of this step is to define this list of key words, which allows carrying out a survey for the intensity evaluation.

3.2.1 Activity 2.1: Definition of the Keywords List

In order to define the keywords for the intended research, the sub-themes from the Advanced Manufacturing workshops were taken into account. Secondly, the key issue raised in the public policies of the United States, Germany and China, as well as reports from the World Economic Forum (WEF) and consulting firms on the subject, were compared to the list of keywords resulting from item 3.1. At the end of this analysis, the final list of key words, divided by theme, will be generated for the search intensity.

3.2.2 Activity 2.2: Survey of research intensity

To raise the search intensity of the selected key words the search engines CAPES, Science Direct and Google Scholar were used. For all of them, each keyword was combined with expressions that define the new industrial revolution as "Advanced Manufacturing" or "Industrie 4.0" or "Industry 4.0", so that the result would show contents in the desired area.

In Google Scholar the search was performed in two ways: considering the presence of keywords only in titles (TITLE) or in any part of the text (ALL). For this search engine only articles, without restriction of theme, and not including appearances in patents or quotations were considered. For Science Direct, similar strategy was used with the difference that the first step would be in the title, keywords and abstract (TITLE-ABSTR-KEY). And for the CAPES journals’ portal, the research is carried out in the title, subject and authors.

The purpose of this differentiation is to increase the variability of the results and to show the important degree of certain keywords for the article in question. When such differentiation is highlighted in the title, abstract or as a keyword, it provides more information, opposed to just being present in the text.

3.3 Step 3: Correlation between Brazilian challenges and worldwide initiatives

This step consists of an analysis of the results obtained so far and a comparison with the actions adopted by the United States, Germany and China in each of the highlighted topics.

3.3.1 Activity 3.1: Survey of initiatives that solve the challenges raised

This activity aims to show a correlation matrix between the challenges raised in the Advanced Manufacturing workshops and initiatives developed by leading industry countries (USA, Germany and China).

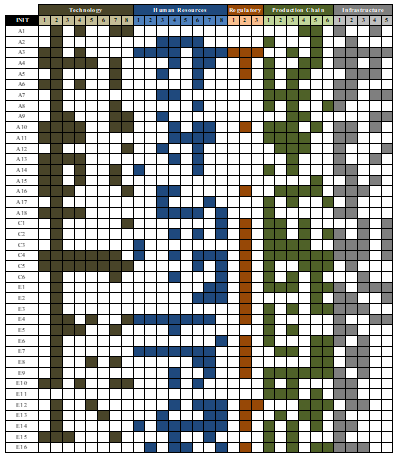

The developed matrix allows the researched initiative to correlate with one or more themes, and the relationship is proven by the initiative's mission or the work developed by it. The final result will be a matrix with the left column bringing the initiatives where "A1" means the first German initiative, "C1" the first Chinese and "E1" the first American, with the numbering increasing until reaching the number of initiatives surveyed by country. On the horizontal, the sub-themes appear within each large theme, shown in total for easy viewing.

3.3.2 Activity 3.2: Analysis of challenges and opportunities to Brazil in Advanced Manufacturing

As a final step, this article links the main initiatives researched to each one of the challenges raised and to its research intensity around the world, in order to highlight the challenge and show methods adopted by other countries in their dealings.

4 RESULTS AND DISCUSSION

This chapter brings the results of this article: a consolidation of challenges for the country in Advanced Manufacturing, and analysis of the intensity research of each main theme, and finally an analysis of the challenges raised and their research focus, relating to initiatives undertaken in other countries that seek to overcome them.

4.1 Step 1: Survey of Brazil's Challenges in Advanced Manufacturing

This step is a validation of the results obtained in a series of workshops that were attended by representatives of the public, industrial and academic sectors (MDIC and MCTI, 2016), as shown in Figure 1, compared to the special survey on the use of digital technology carried out by CNI with several companies (CNI, 2016), consolidating a list of national challenges regarding the progress of the new industrial revolution.

The CNI's Special Survey shows that less than half of Brazilian industrial companies use one of the ten types of digital technologies listed in the survey, which reveals an even more challenging truth for the country to be successful in the new industrial revolution: Brazil is still adjusting to the third industrial revolution (CNI, 2016). On the other hand, the fourth industrial revolution uses technologies present in the current industry, combined with intelligence in data processing, which makes it possible to evolve directly into this new phase.

In the workshops held all over the country, experts from the industrial, academic and public sectors also raised issues that they consider challenges for the country in the sector, which ratify the CNI’s research showing that the adoption of digital technologies will be essential for Brazil's competitiveness in Advanced Manufacturing.

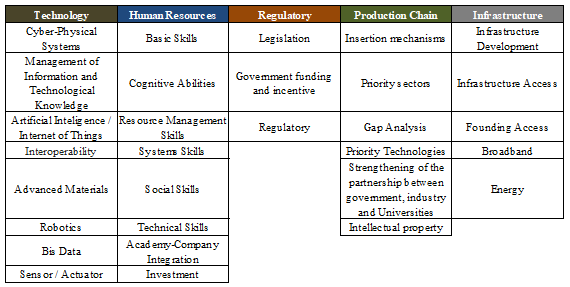

As highlighted in the CNI’s survey, only 48% of the companies that participated in the interview use, at least, one of the listed technologies, including digital and sensorless automation, remote monitoring and production control, Big Data, IoT, among others (CNI, 2016). This low number shows that the points raised in the workshops will really be a challenge, and suggests the insertion of other important aspects mentioned in the CNI's research, such as Big Data Management and Sensors/Actuators. Thus, the final list of challenges raised in the two surveys is shown in Figure 2.

The human factor is also remembered in the CNI’s survey and presents the lack of qualified worker as the main external barrier that delays the adoption of digital technologies. In addition, government investment in new educational models and training programs is mentioned as one of the most important government measures to accelerate the adoption of digital technologies (CNI, 2016). Thus, the final list of country challenges in HR is identical to the final result of the workshops, shown in Figure 1.

In CNI's research, among the main internal barriers to the adoption of digital technologies cited are the high cost of implementation, which can be solved by incentives, and the risk of information security, which requires changes in legislation. Other aspects directly related to regulation present in survey’s results are the absence of appropriate funding lines, lack of technical standards and the establishment of an adequate regulatory framework (CNI, 2016). In this way, the results of the special survey corroborate those of the workshops, making the final listing for regulation identical to that shown in Figure 1.

As a result of the survey there are external barriers to the adoption of digital technologies that are pointed by the industry as some of the main "difficulties to identify technologies and partners" and "the market is not yet prepared (customers and suppliers)". Also, internal barriers are considered important as "Structure and culture" (CNI, 2016), which corroborates the challenges listed in the CNI’s survey, keeping the list of challenges in Productive Chain.

The infrastructure theme is central to the development of Advanced Manufacturing and appears in CNI's research as the most important measure of government to accelerate the adoption of digital technologies, listed as "Promoting the Development of Digital Infrastructure (broadband, sensors)", and the challenge of an inappropriate IT structure also appears as an internal barrier (CNI, 2016). Thus, the final list in the infrastructure theme also remains as shown in Figure 1.

Therefore, the final list of challenges for Brazil in Advanced Manufacturing, divided into the five themes presented, is shown in Figure 2.

Figure 2. Final list of challenges for Brazil in Advanced Manufacturing.

4.2 Step 2: Assessing the Intensity and Relevance of each Challenge in the world

The second step is to evaluate the intensity of research and relevance of each key term. To do this, the first activity of this step is to define a list of words that allows carrying out a survey of research intensity.

4.2.1 Activity 2.1: Definition of the Keywords List

The definition of the list of key words to be used in the research intensity survey was based on the result of step 4. Then it was counterpoised to the public policies of the United States – the National Strategic Plan for Advanced Manufacturing (NSTC, 2012); Germany – Recommendations for implementing the strategic initiative INDUSTRIE 4.0 (ACATECH, 2013); and the reports of the World Economic Forum on Advanced Manufacturing and Human Resources – Future of Jobs (World Economic Forum, 2016). Another source used is a survey conducted by the Deloitte titled Advanced Manufacturing Initiative – Manufacturing & Innovation (DELOITTE, 2015).

It is noted in the above-mentioned plans that the United States bases their investments in public-private partnerships and in lists of ongoing initiatives in the country at that time that may be tied to the development plan in Advanced Manufacturing. The German plan brings the main technical challenges very clearly in order to maintain the strategic position of the country in the sector on the world stage. Both are concerned about the Human Resources theme, hoping that the industries return to the country back from China, where they have searched for low cost in terms of human resources, as a manner of generating more jobs.

On the technological theme, a report published by the consulting firm Deloitte, named Advanced Technologies Initiative - Manufacturing & Innovation, brings a survey with executives from several companies on the technologies related to Advanced Manufacturing in the future. In the list, there are themes already present in initiatives developed in the countries highlighted and their respective importance within each of these, which can be related to the investments involved.

In Human Resources, the report of the World Economic Forum titled Future of Jobs brings major skills related to work in the future. It should be noted that the final list of sub-themes in the Human Resources in the figure 1 is based on the report of the World Economic Forum. Discrepancies between the two results are "Academy-Company Integration" and "Investments", which are not skills but the means to achieve the objectives.

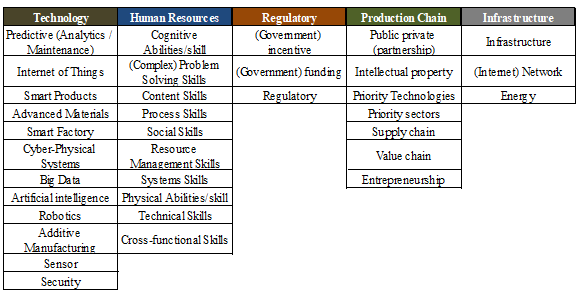

By combining the documents raised in this subchapter and the list of keywords resulting from item 4.1, the proposed list of keywords in Advanced Manufacturing, shown in Figure 3, is the outcome.

Figure 3. Advanced Manufacturing’s Keyword final list.

4.2.2 Activity 2.2: Survey of research intensity

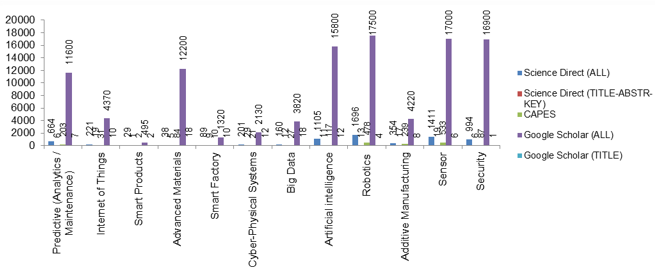

An important issue to guide the destination of the country's effort is to know the rest of the world’s direction, and one way to have that response is to map the intensity of research on a particular subject. In this way, this section brings the search intensity of the final keyword list resulting from the previous subchapter.

For the Technology theme and its keywords highlighted in Figure 3, it is possible to observe that, according to Hermann et al. (Hermann et al., 2015), terms that are components of Industry 4.0, such as Cyber-Physical Systems, Internet of Things and Smart Factory didn’t stand out in the research when compared in a generalized way. Mainly when including the general result of Google Scholar (Figure 4), 9th and 11th, respectively, but present a more consistent result when only more specific results are analyzed, where they are present in titles, abstracts and keywords.

Figure 4. Intensity of research in Technology.

When compared to the survey conducted by Deloitte, the technologies of the future in Advanced Manufacturing do not have compatible research indexes, such as Smart Products, which was only in 12th place in the research intensity. Other terms that present an expressive result, such as sensor are technologies already present in the industry, but considered for their strategic importance in the new industrial revolution and for being listed as one of the challenges for Advanced Manufacturing in Brazil.

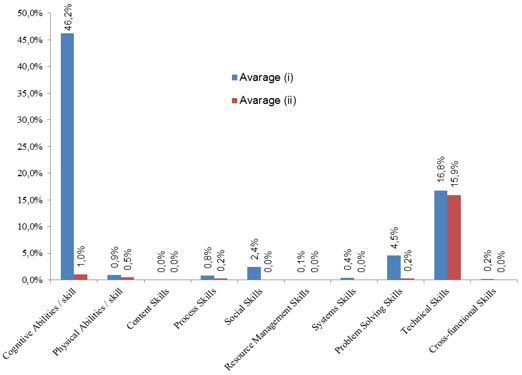

In the Human Resources theme, there is little expressive result of most of the terms, which reveals little research on subjects directly related to the theme, although it is one of the key aspects for Industry 4.0. It is noticed that some subjects, such as Content Skills and Resource Management Skills, had no occurrence.

To better evaluate the importance of each aspect within the theme of Human Resources, a research was conducted of the terms "Human Resource" and "Talent", and the keywords presented show the relevance of the theme in publications such as The Future of Jobs (World Economic Forum, 2016). Also, the percentage of this search is presented for each keyword in Figure 5 – in this result it is considered the total number of occurrences of the keywords in all the search engines (Average i) and also the result, disregarding the Google Scholar (Average ii). In this way, it reinforces the small expressiveness of the keywords researched, mostly desired skills for the professional of the future. The largest concentration of research is based on the challenge of Human Resources management in Industry 4.0, with approximately 49% of the results for the topic in Google Scholar.

Even the poor performance of the keywords searched for the cognitive, technical, social and problem-solving skills presented some prominence.

Figure 5. Proportional result of research intensity for Human Resources.

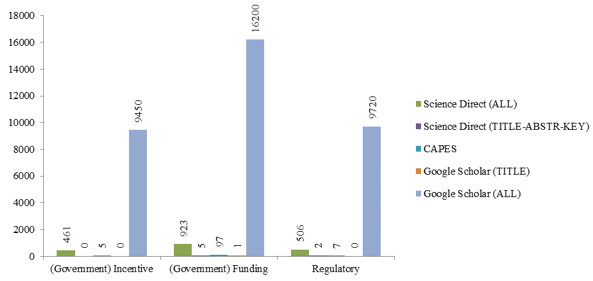

Figure 6 shows relevant results to the occurrence of the keywords of the regulatory theme when searched throughout the text - Google Scholar (ALL) and Science Direct (ALL). This reveals the expressive presence of government funding and incentives in Advanced Manufacturing, which is always expected in innovation projects. Even though these subjects are present in the articles in general, they are not present as key parts in the same articles.

Figure 6. Research intensity in Regulatory.

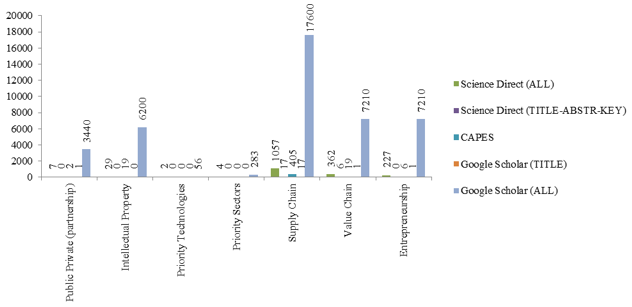

Within the topic Productive Chains, there is a low relevance for the keywords "Priority Technologies" and "Priority Sectors" (Figure 7), which is an expected result in a certain way, since the applications performed are already in significant sectors, using the priority technologies for that. On the other hand, researching in the area of the value/supply chain presented expressive results, confirming the importance of the theme as a key part in Advanced Manufacturing.

Figure 7. Research Intensity in Productive Chain.

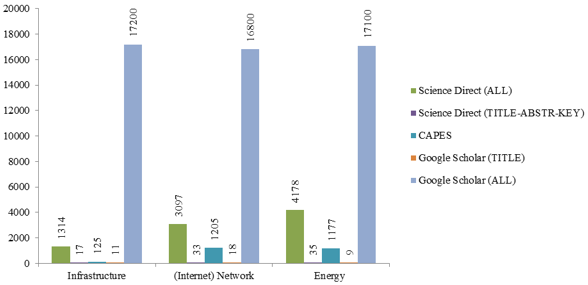

In Infrastructure, it is noted a relevant amount of search for the three keywords examined for generalized and restricted search (Figure 8). The result is expected, since the current moment of the industrial revolution is exactly the foundation for the Advanced Manufacturing, and infrastructure in energy and internet network are essential parameters in this journey.

Figure 8. Research Intensity in Infrastructure.

4.3 Step 3: Correlation between Brazilian challenges and worldwide initiatives

This step shows an analysis of the found results and a comparison with the actions adopted by the United States, Germany and China in each of the highlighted topics.

4.3.1 Activity 3.1: Survey of initiatives that solve the challenges raised

In order to assist in proposing solutions to the challenges posed to Brazil in Advanced Manufacturing (Figure 2), global initiatives (Figure 9) that, somehow, deal with similar issues were pointed out. Initiatives developed in the United States (E), Germany (A) and China (C), which have more advanced programs in the area, and the correlation matrix are shown in Figure 10.

In total, 40 initiatives were shown around the world, 18 in Germany, 16 in the United States and 6 in China. In general, the initiatives are public-private partnerships that involve the participation of universities.

Figure 9. Researched Initiatives.

Figure 10. Correlation Matrix of challenges and global initiative.

Correlating the Brazilian challenges identified by the experts representing government, industry and universities with the worldwide initiatives in Advanced Manufacturing, stands out:

• In technology, information and knowledge management are present in almost all initiatives, more precisely in 95% of them. The technologies, such as Digitization/Cyber physical Systems, Big Data Management, Artificial Intelligence/Internet of Things and Interoperability are considered essential, as they are part of a third of the same initiatives. Meanwhile, Sensors/Actuators, New Materials, and Collaborative Robotics have 22%, 15% 7%, respectively.

• In Human Resources, most initiatives are committed to disseminate knowledge, involving at least one item related to the topic. The development of technical and systemic skills is the one that has the greatest correlation with the initiatives, reaching more than half of them. Another highlight is university and company integration, which shows that these partnerships are the key to the formation of the new workforce in Industry 4.0, and is present in 41% of the initiatives. The development of cognitive, basic and social skills has still slight alignment with the initiatives, having correlation with 10%, 17% and 20% of them.

• In regulatory, government funding and incentives are the ones that show the highest correlation with the initiatives, showing the importance of public-private partnerships for the development of Advanced Manufacturing. Legislation and regulatory frameworks present small correlation to initiatives with 5% and 7%, respectively however, the governments of the countries surveyed closely follow the progress of the new industrial revolution, always attentive to the needs.

• In the topic of productive chains, the question of insertion mechanisms presents a greater correlation with the initiatives with 68%, which is expected due the initial phase of the process. Shortly afterwards, with a correlation with 63% and 56% appears the questions of gap analysis and Strengthening of the partnership between government, industry and universities, respectively. And lastly, the priority sectors and technologies and intellectual property are related to, approximately, one-third of the initiatives – it is worth emphasizing that the initiatives themselves are developed in the sectors and with the required technologies, which, in some way, makes these requirements always present.

• In terms of infrastructure, the development and access of infrastructure necessary for the success of the Advanced Manufacturing are priorities and are present in 71% and 63% of the initiatives, respectively. Access to government funding is addressed by 39% of the initiatives, while the need for broadband and energy is directly correlated with approximately 30% of the initiatives, but, indirectly, they represent the heart of the fourth industrial revolution.

In general, it is possible to verify the existence of, at least, one initiative related to each challenge raised for the development of Advanced Manufacturing in Brazil. It is also noted that an initiative, in general, covers more than one challenge, one of them related to the Human Resources sector, even though it is not exclusively dedicated to this topic. In this way, seeking partnerships with educational institutions, the initiatives help to shape the future and capacity of professionals that are already in the job market.

4.3.2 Activity 3.2: Analysis of challenges and opportunities to Brazil in Advanced Manufacturing

With the results presented in line with the most advanced countries in the industrial sector, the first step necessary for the development of Industry 4.0 in Brazil was given by the MDIC and MCTI with the execution of workshops by the country. Moreover, the results of CNI’s 66 survey showed the challenges that has to be faced, and helped to understand the current level of Brazil in the use of digital technologies.

The last stage goal is to analyze the challenges raised, linking them with initiatives and research that are being carried out by the other countries that show methods that could work to help in the formulation of a national strategy to the development of Advanced Manufacturing in Brazil.

As a subject of a public policy, one example is conducted by the United States with the program Manufacturing USA, a centralizing body of the program with representatives of the government, industry and universities, with the mission to convene and allow public-private partnerships conducted by industry with a focus on manufacturing innovation, and engaging universities in the country, in addition to acting with integrator of the initiatives generated to facilitate collaboration and information sharing (Manufacturing USA, 2016). Such a program would also help to spread the technology, solving one of the main obstacles cited in the research carried out by the CNI: lack of knowledge.

The union of these tree sectors will play a decisive role for the success of the Brazilian enterprise in the development of Advanced Manufacturing. The country needs to change the sequence of consecutive falls in competitiveness – according to the ranking published by the World Economic Forum, the country occupies only 81st place in the ranking of the most competitive economies of the world – and this joint effort between government, industry and academic sector will be decisive to improve it. The deterioration of factors considered basic to competitiveness, such as economic environment, financial market development and, mainly, innovation capacity are the reason of the consecutive decline in the position (Alvarenga, 2016).

On the subject of projects, a way to increase the probability of success would be, firstly, to define the priority sectors of the industry, as exposed in the opinions of the experts during the workshops, and to focus efforts on the technologies necessary for the development of these specific sectors. Sectors such as mining, agribusiness and aeronautics, where the country has some global prominence, are some of the main candidates. The automotive sector, one of the main players in the industrial sector of the country, also deserves special attention, encouraging multinational companies to import technologies developed in other countries to Brazil, which will stimulate the entire value chain to enter the process.

To help this importation and essential items to develop Advanced Manufacturing in Brazil, and also to help export our products, which are so important to our trade balance, the country could count on an initiative such as the National Export Initiative (NEXT), but also related to imports (Manufacturing USA, 2016). As an example of this need, technologies already present in the industry worldwide, as robotics, have low utilization rate in the country, precisely because of this difficulty to import due to legislation and high taxes.

Another important aspect to the success of Advanced Manufacturing in Brazil is the application of the technologies in an integrated way in all the stages of the value chain, including logistics. For this, several initiatives can be followed, especially “Smart Face”, which integrates the production process of electric cars with the entire logistics process involved (Autonomik Industrie 4.0, 2016). Because of this value chain initiative, other initiatives, such as “Hub2Move” – a system for material flow (Fraunhofer IML, 2015) – and “InBin” – intelligent containers that help process decision making by providing supply data (Fraunhofer IML, 2016) – could be developed.

From these initiatives several products that can lead to the generation of new companies will arise. With an eye on these opportunities, the creation of an initiative such as the American initiative “Startup America”, which would foster entrepreneurship to meet the demands of the future market, would be very relevant (Manufacturing USA, 2016). In addition to developing cognitive skills in those involved in that, would allow the emergence of new entrepreneurs and, consequently, new businesses and jobs. Partnerships between large companies and startups can accelerate the process of developing new products, removing the slowness of the academic sector. To this end, specific calls for to promote this type of partnership and improvement of intellectual property laws are necessary.

The issue of infrastructure necessary for development is also a matter of concern of the experts. In order to encourage the process, the government can launch specific funding programs to the development of structuring technologies such as broadband and mobile internet. Investment in basic industries should also be the focus of the advance Industry 4.0 in Brazil, in line with the Chinese program, which aims to increase its self-sufficiency in the components and base materials of its industry, increasing the level of our self-sufficiency and, thus, control the value chain.

Also, in terms of infrastructure, Brazil needs to increase access and promotion to existing network, such as EMBRAPII (2016) and SIBRATEC (REDE TIC, 2016), optimizing the use of these structures and enabling the development of projects, especially for small and medium-sized companies. These networks are made up of technology labs and can be similar to the “IIC Testbeds initiative” - test bench of the Industrial Internet Consortium in the United States (Crawford, 2016).

In the energy aspect, Brazil is already one of the pioneers in some types of renewable energy as in the production of energy from biomass, and ethanol is the main biofuel (Biomassa & Bioenergia, 2016). Other important sectors in this area are wind and solar energies, as the country still has a great development capacity, for their use has consistently increased. In this regard, the creation of an initiative such as the US Clean Energy Manufacturing Initiative (Department of Energy, 2016), combined with some kind of government incentive to consume such energy sources, would further strengthen the use of renewable energy, especially in the industrial sector, aligning the country's development with the terms of the Kyoto Protocol.

From the technological point of view, the country needs a public policy to encourage the use of technologies adhering to the Advanced Manufacturing, such as robotics, sensors and actuators. Currently, the country has an average age of 17 years in the industrial sector, compared to five in the United States, and has a low rate in terms of robot use by the industry, mainly due to the high rates applied to the sector. Initiative such as the “National Robotics Initiative” (Manufacturing USA, 2016), developed in the United States with the mission of accelerating the development and use of robots employed in the industry of the country, working side by side in cooperation with people, can be a way for our country.

Another point is that approaching the industries of the various sectors for the development of Advanced Manufacturing is essential for the country. The Brazilian IT industry ranks 7th in the world industry ranking in 2014, with an investment of $ 60 billion, corresponding to 46% of Latin America's investment (Rio Negócios, 2016), and it is also prominent in other industrial sectors such as aeronautics. In this way, the country needs a management that integrates the various sectors, stimulating economically and providing income to obtain the other resources that will be demanded.

To operate all this gear, the main resource needed will be the talent, according to a worldwide survey conducted by Deloitte (Deloitte, 2016). The Human Resources issue in Brazil needs drastic changes – Brazil forms only 40,000 engineers a year, while the United States makes 237,000 and China 650,000, and 35% of those are trained. In addition, the quality of engineers trained in the country is far from ideal, which brings losses of around 15 billion dollars per year (Brito, 2013).

Thus, in addition to increasing the number of professionals that will be trained for Industry 4.0, Brazil should increase the quality of its trainees. To this end, the country's universities should approach industry in order to capacitate professionals to meet the challenges they will face and seek to develop not only technical skills, but also systemic and multidisciplinary skills – for example, leaving the theoretical and evaluations and moving on to integrated projects, working on the ability to solve complex problems. In addition to the universities, technical courses to meet specific needs will be extremely necessary – qualified professionals in the various areas of information technology, robotics, among others, will be demanded by the new industry. Not only the new professionals should be different – training by increasing the technological competence within the companies will be necessary.

Initiatives such as the German Academy Cube (Acedemy Cube, 2016) can be followed, in order to bring quality distance education, focused on market demands, working in conjunction with a company selection system, making the professionals fit to the needs of the industry, directing them to the market.

5 CONCLUSIONS

The new industrial revolution is already ongoing in some countries, and they are taking steps to seize the moment and maintain or increase their manufacturing markets. Countries such as Germany, the United States, and China point to Advanced Manufacturing as one of the main economic pillars of the future and, for this reason, have already made heavy investments in the sector in recent years. Brazil, a leading country in some industrial sectors, needs to rush and start the industrial race in an organized and focused way in order to surf this new wave and maintain or increase its markets.

Aimed to assist this process, the present work has consolidated two national surveys on the subject to get the list of the main challenges to the development of Advanced Manufacturing in Brazil, which was compared to the most relevant challenges in the world scenario, being evaluated from a quantitative perspective in the research intensity, in order to show where the greatest efforts are being used. Finally, a correlation of the main challenges to the initiatives developed by Germany, China, and the United States is sought, with the aim of presenting a possible method for progress in our country.

At the end of this process, the main results are:

• Less than half of the national industries use digital technologies and one of the main factors is the lack of knowledge. The creation of a public policy with a central body, aiming to integrate the initiatives to create and facilitate the collaboration and share information in the mold of the US initiative “Manufacturing USA”, could help with this challenge.

• The definition of industry priority sectors is an essential step for enabling the focus of efforts on the technologies needed to develop these specific sectors. For each technological challenge to be faced, the creation of initiatives developed in public-private partnerships with government incentives, overcoming one of the main barriers listed by industry, the high cost, can be a way to achieve success.

• Another barrier to the use of digital technologies in the industry view is the lack of skilled workers. The Human Resources theme is critical and is the most important to the success of Industry 4.0, according to research conducted by Deloitte, and will require a professional that is different from the current standard. To achieve this, the approach between the academic and industrial sectors will be decisive, both for the training of the professional of the future and for the qualification of the current human resource. This process can be established within the initiatives to be developed, with a multidisciplinary character, or through dedicated initiatives, such as the German “Academy Cube”.

ACKNOWLEDGMENTS

Guilherme A. B. Mancilha acknowledges the Manufacturing Competence Center and all its personnel for all the help during the period of this work.

REFERENCES

Academy Cube (2016), The world’s smartest talent platform, available from: http://www.academy-cube.com/about-us (accessed 25 Nov 2016). Alvarenga, D (2016), Brasil cai para a 81ª posição em ranking de competitividade de países, available from: http://g1.globo.com/economia/noticia/2016/09/brasil-cai-para-81-posicao-em-ranking-de-competitividade-de-paises.html (accessed 25 Nov 2016).

AUTONOMIK INDUSTRIE 4.0 (2016), Smart Face, available from: http://www.smartfactoryplanning.de/projekt/beschreibung.html (accessed 25 Nov 2016).

Biomassa & Bioenergia (2016), Brasil lidera ranking mundial de uso da biomassa na produção de energia, available from: http://www.biomassabioenergia.com.br/imprensa/brasil-lidera-ranking-mundial-de-uso-da-biomassa-na-producao-de-energia/20130926-114923-f300 (accessed 29 Nov 2016).

Brito, A. (2013), País perde US$ 15 bi com má formação de engenheiro, available from: http://www.seesp.org.br/site/cotidiano/818-pais-perde-us-15-bi-com-ma-formacao-de-engenheiro.html (accessed 28 Sept 2016).

Confederação Nacional das Indústrias - CNI (2016), Sondagem Especial 66 – Indústria 4.0, available from: http://www.portaldaindustria.com.br/cni/publicacoes-e-estatisticas/estatisticas/2016/05/1,88118/sondesp-66-industria-4-0.html (accessed 20 Oct 2016).

Crawford, M. (2016), Industrial Internet of Things: Understanding and Using the Industrial Internet Consortium’s Reference Architecture, available from: https://www.iiconsortium.org/japan-forum/SAP-June-3-presentation.pdf (accessed 30 Nov 2016).

DELOITTE (2015), Advanced Technologies Initiative – Manufacturing & Innovation, available from: https://www2.deloitte.com/us/en/pages/manufacturing/articles/advanced-manufacturing-technologies-report.html (accessed 30 Nov 2016).

DELOITTE (2016), 2016 Global Manufacturing Competitiveness Index, available from: https://www2.deloitte.com/content/dam/Deloitte/us/Documents/manufacturing/us-gmci.pdf (accessed 28 Sept 2016).

Department of Energy (2016), Clean Energy Manufacturing Initiative, available from: http://energy.gov/eere/cemi/clean-energy-manufacturing-initiative (accessed 29 Nov 2016).

EMBRAPII (2016), Unidades EMBRAPII, available from: http://embrapii.org.br/categoria/unidades-embrapii (accessed 30 Nov 2016).

Exame (2014), A era das fábricas inteligentes está começando, available from: http://exame.abril.com.br/revista-exame/edicoes/1068/noticias/a-fabrica-do-futuro (accessed 12 Sept 2016).

FORBES (2016), Why China Can Dominate Next-Generation Manufacturing, available from: http://www.forbes.com/sites/helenwang/2016/08/31/why-china-may-dominate-next-generation-manufacturing/#1cea36fc13c0 (accessed 29 Nov 2016).

Fraunhofer IML (2015), Hub2Move, available from: http://www.industrie40.iml.fraunhofer.de/en/ergebnisse/hub2move.html (accessed 25 Nov 2016).

Fraunhofer IML (2016), InBin - Intelligent Bin, available from: http://www.industrie40.iml.fraunhofer.de/en/ergebnisse/inbin.html (accessed 25 Nov 2016).

Hermann, M., Pentek, T., Otto, B. (2015), Design Principles for Industrie 4.0 Scenarios: a Literature Review. Technische Universität Dortmund.

Manufacturing USA (2016), Initiatives, available from: https://www.manufacturing.gov/federal-initiatives (accessed 25 Nov 2016).

Manufacturing USA (2016), Manufacturing USA – the National Network for Manufacturing Innovation, available from: https://www.manufacturing.gov/nnmi (accessed 25 Nov 2016).

Ministério da Indústria e Comércio – MDIC (2016), MDIC promove debate sobre manufatura avançada, available from: http://www.mdic.gov.br/noticias/112-inovacao/960-mdic-promove-debate-sobre-manufatura-avancada (accessed 28 Sept 2016).

Ministério da Indústria e Comércio e Ministério da Ciência, Tecnologia, Inovações e Telecomunicações – MDIC e MCTI (2016), Perspectivas de Especialistas brasileiros sobre a Manufatura Avançada no Brasil: um relato de workshops realizados em sete capitais brasileiras em contraste com as experiências internacionais, available from: http://www.mdic.gov.br/noticias/2130-mdic-lanca-estudo-sobre-oportunidades-e-desafios-para-a-manufatura-avancada-no-pais (accessed 05 Dec 2016).

National Academy of Science and Engineering – ACATECH (2013), Recommendations for implementing the strategic initiative INDUSTRIE 4.0, Final report of the Industrie 4.0 Working Group, available from: http://www.acatech.de/fileadmin/user_upload/Baumstruktur_nach_Website/Acatech/root/de/Material_fuer_Sonderseiten/Industrie_4.0/Final_report__Industrie_4.0_accessible.pdf (accessed 20 Sept 2016.

National Science and Technology Council – NSTC (2012), A National Strategic Plan for Advanced Manufacturing, available from: https://www.whitehouse.gov/sites/default/files/microsites/ostp/iam_advancedmanufacturing_strategicplan_2012.pdf (accessed 25 Sept 2016).

President’s Council of Advisors on Science and Technology (2011), Report to the President on Ensuring American Leadership in Advanced Manufacturing, available from: https://www.whitehouse.gov/sites/default/files/microsites/ostp/pcast-advanced-manufacturing-june2011.pdf (accessed 19 Sept 2016).

PWC (2016), What China plans to do in 2016 and the next five years, available from: http://www.pwccn.com/webmedia/doc/635938893466737307_govt_work_review_mar2016.pdf (accessed 25 Nov 2016).

REDE TIC (2016), Sobre o SIBRATEC, available from: http://www.redetic.rnp.br/sobre-o-sibratec (accessed 30 Nov 2016).

Rio Negócios (2016), Brasil ocupa o 7º lugar em ranking mundial da indústria de TI, available from: http://rio-negocios.com/brasil-ocupa-o-7o-lugar-em-ranking-mundial-da-industria-de-ti/ (accessed 29 Nov 2016).

World Economic Forum (2016), The Future of Jobs – Employment, Skills and Workforce Strategy for the Fourth Industrial Revolution, available from: http://www3.weforum.org/docs/WEF_Future_of_Jobs.pdf (accessed 25 November 2016).

Received: 11 Sep 2017

Approved: 08 May 2018

DOI: 10.14488/BJOPM.2018.v15.n2.a4

How to cite: Mancilha, G., Gomes, J. (2018), “Comparative analysis between challenges in a Brazilian perspective and worldwide initiatives in Advanced Manufacturing”, Brazilian Journal of Operations & Production Management, Vol. 15, No. 2, pp. 209-223, available from: https://bjopm.emnuvens.com.br/bjopm/article/view/395 (access year month day)