Warehouse design: a systematic literature review

Augusto da Cunha Reis1, Cristina Gomes de Souza1, Nayara Nogueira da Costa1, Gustavo Henrique Cordeiro Stender1, Pedro Senna Vieira1, Nélio Domingues Pizzolato2

1 Federal Center for Technological Education Celso Suckow da Fonseca – CEFET/RJ

2 Catholic University of Petrópolis - UCP

1. Introduction

Warehouses are seen as an opportunity to improve operation optimization and information flows, to reduce inventory levels and to enable more agile distribution (Vrijhoef et Koselka, 2000). The successful performance of a warehouse depends on appropriate strategy, layout, warehouse operations and material handling systems (Lehrer et al., 2010). For Gu et al. (2010), warehouse design problems involve five groups of decisions: determination of the general structure of the warehouse (conceptual design); its sizing; layout calculation; warehousing equipment selection; and selection of its operational strategy. In addition, a warehouse project must also include definitions of policies about order fulfillment/picking, stocking, and stock rotation (Koster et al., 2007; Chan et Chan, 2011). Despite the theme’s importance, a review of the literature reveals few studies that systematically cover the warehouse design methods (Koster et al., 2007; Baker et Canessa, 2009; Gu et al., 2010). Although a vast amount of material dealing with the specific aspects of a project do exist, there seems to be no syntheses of these techniques that could provide a base for a general warehouse concept (Rouwenhorst et al, 2010). According to Gu et al. (2010), there is a gap between the published research and the practice of projecting and operating warehouses. The authors state that, to establish this interface between academia and practice, there must be an improvement in the state-of-the-art for warehousing project methodology. Given this context, the object of this article is to present a systematic review of the warehouse design literature, covering the period 1999-2015. The purpose is to identify the main aspects that have been covered in those studies in a way that can aggregate value for professionals in this area and contribute to future research about the theme. For the sake of simplification, in this study the term warehousing refers to installations whose main function is stocking as well as to those whose main function is distribution.

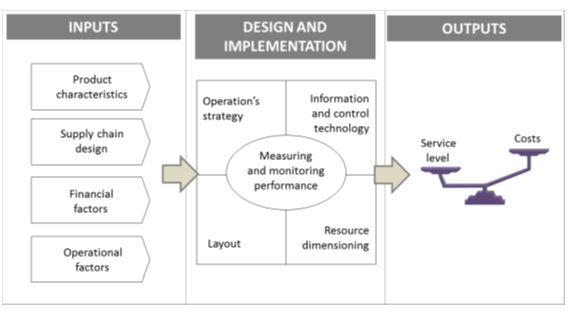

To facilitate analysis of the main points taken up in the literature, a framework that considers three groups of relevant factors in warehouse design has been created: inputs; design and implementation; and outputs. The difference between this review and others (Van den Berg, 1999; Rouwenhorst et al., 2000; Gu et al., 2010) lies in a more holistic vision of the warehouse designing and the research methodology employed. A systematic review of literature facilitates the summarization of studies through procedural protocols that objectively validate them (Khan et al., 2001; Tseng et al., 2008). The remaining of the paper is composed as follows: Section 2 examines the framework for systematic review; Section 3 describes the literature methodology; Section 4 portrays (enumerates) and classifies the articles selected for the study, while Section 5 draws some conclusions.

2. A framework for systematic reviewing

According to Lambert et Cooper (2000), supply-chain management entails integrating key business processes. In this context, warehouses are important hubs in the supply chain in which they operate. For better understanding of the process of designing a warehouse, the main factors that impact the decisions are visualized, and a systematic review of the literature oriented by a framework, based on an initial bibliographic study, is formulated. The framework formulated was structured in three parts: inputs; design and implementation; and outputs, as illustrated in Figure 1.

Figure 1. Proposed framework for systematic literature review on warehouse design

Source: Based on the initial bibliographic study

2.1 Inputs

The inputs consist of the key factors that influence decisions in warehouse designing, whether they are of internal or external nature. They serve as starting points for the design and implementation of activities, which are:

-

Product characteristics: decisions such as warehousing operation’s strategy are influenced by the properties and characteristics of the products handled (Chow et al., 2005; Koster et al., 2007);

-

Supply chain design: the choices made by the warehouse units must consider the whole supply chain from suppliers to final clients. This requires a profound understanding in terms of how the various elements and activities are integrated (Baker, 2004; Chow et al., 2005; Gill, 2009; Koster et al., 2007; Tompkins et al., 1996; Cordeau et al., 2006; Demirel et al., 2010);

-

Financial factors: warehousing costs are, to a great extent, determined during the design and implementation phases, and they should be projected in the most efficient form, with minimum investment and operational costs (Rouwenhorst et al., 2000; Baker et Canessa, 2009; Hackmann et al., 2001);

-

Operational factors: it is necessary to define the technical capacity of an installation before determining its design, which entails a deep understanding of the products and the orders (Rouwenhorst et al., 2000). Two aspects should be considered: warehouse capacity and processing/throughput capacity. The processing rate is an important system productivity indicator and it is directly linked with order picking/fulfillment methods (Hackman et al., 2001). Before implementing the design phase, the effective total space utilization must be carefully defined (Gu et al., 2010).

2.2 Design and implementation

The warehouse design and implementation phase shall consider the following main aspects:

-

Layout: According to Ligget (2000), in sites layout problems are linked to the allocation of activities in the spaces, and may require a design solution in the case of reallocation of space in an already existing structure.

-

Operation’s strategy: It is a vital part of the process of warehousing design. The focus is to define what the operation’s strategy entails, as this will greatly affect the system as a whole. This subgroup was divided into the four main activities of warehouse installations, which are: receiving/expediting, stocking, order picking/fulfillment, and cross-docking;

-

Resource dimensioning: The goal is to combine all factors, such as levels of warehousing equipment employment and the degree of automation in a way that total stocking costs are minimized without affecting the level of processing required;

-

Information and control technology: Mason et al. (2003) affirm that information technologies enable gauging, controlling and optimizing warehousing activities, making them key factors in supply chain flow integration;

-

Measuring and monitoring performance: For long-term design evaluation, performance criteria have to be clearly and precisely defined (Gu et al., 2010).

2.3 Outputs

Output represents the objective for which a warehouse is conceived. The most common objectives are: to maximize the service level in resource-restricted situations, such as manual labor, machinery, or capital (Koster et al., 2007) and/or to minimize the costs of implementation and operation in a way that fulfills all the orders, without exceeding the operational prerequisites (Amirl, 2006). According to Koster et al. (2007) a service level is composed of a variety of factors, such as the average and variations in delivery time and the accuracy of picking and fulfillment. Baker et Canessa (2009) and Pan et al. (2014) emphasize that, initially, it is impossible to reach an ideal solution/output, given the high number of possibilities and combinations of subgroups of decisions in the design and implementation phases. For the authors, the final design should incorporate both qualitative and quantitative aspects. Thus, it is necessary to strike a balance between the implementation and operational costs of warehousing and the target service level, given that improved service levels imply higher logistics costs.

3. Research methodology

This study presents a systematic review of the warehouse design literature. According to Kirca et Yaprak (2010), it entails employing an analysis technique that synthesizes the results of the diverse published studies on a specific issue. In this way, a systematic review contributes to mapping, consolidating, and developing a theory (Seuring et Gold, 2012) as well as identifying new trends’ structural forms, fostering the evolution of knowledge in a research area (Tjahjong et al., 2010).

Although a number of recent accounts on physical distribution, logistics, and supply-chain management based on systematic reviews of the literature may be identified (e.g. Carter et Easton, 2011; Gligor et Holcomb, 2012; Denk et al., 2012; Pilbeam et al., 2012; Wong et al., 2012; Winter et Knemeyer, 2013), the issue of warehouse design has not yet being addressed. Considering the proposal of Kirca and Yaprat (2010), the study was structured into the following stages.

The first stage consisted in defining the scope of the research and elaborating a framework based on a systematic review of the literature. This framework was constructed starting from the initial bibliographic research.

The second stage refers to data collection, corresponding to the study of articles published on warehouse design listed in the Science Direct database, considering indexed articles in the areas of: “business management”; “decision sciences”; and “materials science”. As a search strategy, the terms “warehouse design” and “facility planning” and “logistics” were employed. Since any research involving systematic reviews of literature generally include a minimum of ten years, the study covered the years 1999 through 2015 (Yang et al., 2006; Li et Cavusgil, 1995; O’Donnell et David, 2000; Ngai et al., 2011; Ngai et al., 2008).

In the selection of articles, those that failed to meet the following requirements have been excluded from the study: if they had no abstract, if their complete texts were not available or if they had no relation to any group or subject in the framework proposed. In this way, of the 239 documents accessed in the initial phase of the study, 71 publications were evaluated and became the object of analysis for the present study.

The third stage was the examination of the selected full-paper articles. For this evaluation, a checklist was created covering all the groups and subgroups that compose the framework, as well as general and additional information from the articles. General information looks to data that identify the publication, while additional information looks at the register of other relevant aspects such as: justification or motivation for the work; warehouse design concepts; and other commentaries considered important.

During the reading process, we noted that the majority of articles about warehouse design were correlated with mathematical models. Research about warehouse design and operations has been conducted for almost half a century and, as a result, an extensive variety of methodologies, algorithms, and empirical studies have been generated (Gu et al., 2010). Thus, the analysis covered the characteristics of the studies, classified as theoretical/empirical or as a quantitative/qualitative sense. In the qualitative part of the study, information was collected about the type of models used, data characteristics (deterministic or stochastic), and about the solution method and model validation. To finalize, the data extracted from the selected studies were synthesized, critically analyzed, and some conclusions were drawn.

4. Results

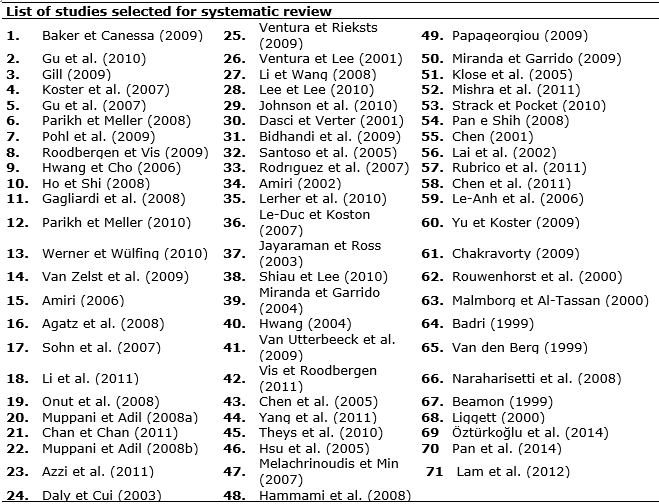

The 71 articles that underwent analysis are listed in Table 1. First, the general data about the publications are presented and then the groups and sub-groups that make up the frameworks are analyzed.

Table 1. Articles selected for review

Source: Authors

4.1 An overview of the publications

Among the material covered we may classify: 46 articles had a strictly theoretical focus (without any explanations of practical applications); 22 presented a theoretical-empirical focus (validation of theoretical contributions using real data); and three had an empirical focus (each one limiting itself to the application of a theory already being used to solve practical problems). Regarding the nature of the variables researched: 54 were classified as quantitative; and 17 as qualitative.

This result is coherent with the fact that many studies are centered on the optimization of warehouse use through the application of mathematical models. Nevertheless, there is evidence that this area is not consolidated and is still a frontier for understanding.

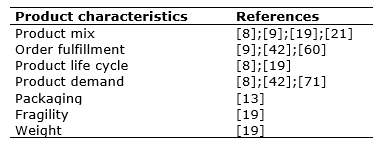

4.1.1 Product characteristics

Table 2 relates the articles that cover product characteristics, which can be categorized as physical or behavioral. Physical characteristics are those visible features that have an impact on warehousing and product movement. Behavioral characteristics, on the other hand, are those that are related to dynamic product flows. These characteristics have been receiving the most attention in the literature on the subject.

Table 2. Product characteristics that influence warehouse design decisions

Source: Authors

The literature points out that it is also necessary to forecast an increase in product variety over time [8]. A way of dimensioning this characteristic is the rate of rotation, which is nothing more than the speed at which products circulate on the shelves [19].

4.1.2 Supply-chain design

At a strategic level, decisions fall back on network configurations, which are: number of locations; capacity; and installation technology ([30]; [31]; [32]; [48]; [49]; [66]). At a tactical level, decisions are understood to be an attribute of each marketing region of one or more locations, such as supplier selection, distribution channels, and means of transport, which impact network connectivity ([31]; [32]; [48]; [49]).

Simpler supply-chain design models that consider capacity are multi-product; they consist of a network of two or more layers, that is, plants and clients, and deal with the question of sharing products and distribution stocks over the whole chain ([15]; [30]; [31]; [37]; [41]). However, these structures are not inclusive to the point of considering the interaction between the locations of the installations in the network and inventory control decisions, as well as the impact of this last item on network configurations. Article [48] considers this question, motivated by the risk of backlash posed to the supply chain.

Qualitative studies, in turn, cover e-commerce ([16]); [24]), localization (location) ([48]), optimization of the manufacturing supply chain ([49]), and review of state-of-the-art models for distribution systems ([51]).

The main objectives for locating a consolidation and distribution warehouse are: cost reduction; to achieve economies of scale by transporting large quantities of cargo between centers ([15]); ([33]); to deal with variability caused by factors such as the seasonality of products and/or production and transport of lots (batches) ([5]); to maintain a high customer service level ([6]); and to embed flexibility into the chain to enable agility in responding to market changes ([15]).

This family of problems typically assumes a linear cost function, and it is considered that client demands follow a deterministic standard ([39]); ([40]); ([51]). The majority of these studies utilize methods such as the center of gravity, the set covering problem, and the p-median model ([40]).

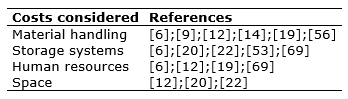

4.1.3 Financial factors

Among the economic-financial considerations, it is important to gauge two main costs: operational costs; and asset investment ([2]); ([62]); ([69]). Table 3 presents the costs considered in the scope of the warehouse design. Note the prevalence of operational costs over investment questions. No articles were found dealing with the issue of depreciation.

Table 3. Costs considered in the studies analyzed

Source: Authors

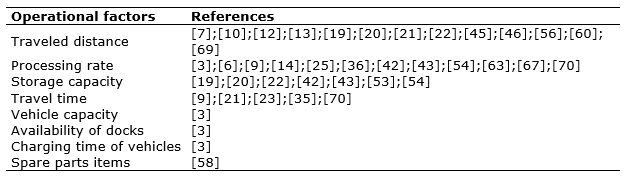

4.1.4 Operational factors

The operational factors most utilized in the studies comprising this review are: the throughput rate and the traveled distance. Many authors contend that the order fulfillment/processing rate is directly related to the distance traversed by the picker and the time it spends ([7]; [10]; [12]; [13]; [19]; [20]; [21]; [22]; [42]; [45]; [46]; [54]; [56]; [60]). The prevalence of these factors over others demonstrates that recent trends in fabrication and distribution have made project designs to embrace more complex performance criteria. Table 4 shows the operational factors considered in the articles in the scope of warehouse design.

Table 4. Operational factors considered in the models

Source: Authors

4.2 Design and implementation

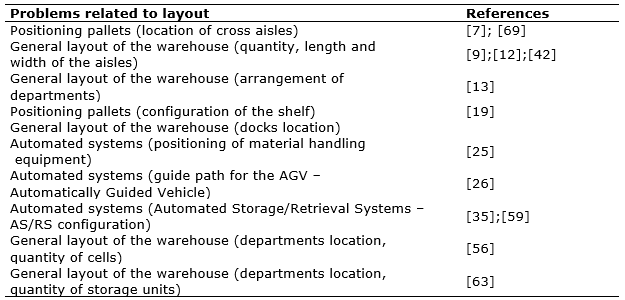

4.2.1 Layout

Table 5 registers the articles that deal with layout and an associated problem, in accordance with the main goal of the article [2]. Note that the problem with the most coverage was the question of general warehouse layout, and more specifically, concerning aisle quantity, length and width.

Table 5. List of articles about layout and problems covered

Source: Authors

Articles [4] and [19] consider that a layout project involves two sub-problems: implementation (issues); and layout inside each system, also referred to as the internal layout project or the aisle configuration problem. In addition to these factors, there are many other qualitative factors to be analyzed, such as safety and aesthetics ([01]).

4.2.2 Operations strategy

An important aspect of warehouse design consists of those operational strategies that, once selected, have great impact effects on the (global) system and are not susceptible to frequent alterations. Two main operational strategies are presented: the stocking strategy and the order separation strategy. In addition, the decisions necessary for configuring and implementing the receiving/expedition and cross-docking strategies are presented.

4.3 Receiving and expediting

In the receiving area, products may be checked-in, transformed, random quality-control checks carried out, and/or goods held for movement to the next process ([5]; [19]; [62]; [65]). A label is attached to the cargo for identification purposes ([65]). In the expediting area; orders are confirmed, classified, packaged, and transported in trains, trucks, or any other mode of transport specified, constituting the final phase ([5]; [19]; [62]).

In the expedition process, orders that are ready for shipment and the trucks are allocated to docks through a policy of dock assignment ([62]). A dock performance indicator was introduced to verify the adequacy of docks to support a (set) given level of cargo activity. A simulation experiment was designed, and the model was tested to check the result’s validity ([5]; [19]; [62]; [65]).

4.4 Stocking

The SLAP (storage location assignment program) is the choice of a rule to be used in assigning products to their stocking locations ([4]; [11]; [53]; [52]).

A stocking strategy may follow several policies such as: random in nature, in which a product may be placed in any available location (whatever location is available) at the moment; dedicated in nature, in which stocking locations are dedicated to (fixed, or, in other words, can only be occupied by) a specific product; or specified by class, in which products are positioned according to some pre-established criteria, such as popularity, maximum inventory, or stock rotation ([5]; [7]; [6]; [11]; [19]; [20]; [21]; [22]; [54]; [56]; [58]; [62]; [63]; [65]; [69]).

In addition to decisions about where to locate products, it is necessary to devise a policy about division of stocking space, which may either be based on an ABC classification or on product categories ([4]; [8]; [19]; [62]; [65]).

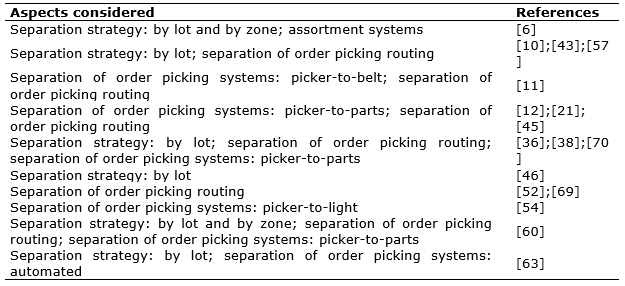

4.5 Order picking

First, it is necessary to define which of the three picking strategy existing concepts is to be used in an operation: lot separation; zone separation; or wave separation ([2]; [4]; [5]; [6]; [8]; [10]; [19]; [20]; [36]; [43]; [46]; [54]; [60]; [62]; [65]).

The process of rotating or sequencing picker movements inside a warehouse is also a way of optimizing the activities. The processes are discrete, by lot, or by zone ([5]; [11]; [19]; [20]; [21]; [36]; [42]; [43]; [45]; [54]; [56]). Picker rotation is a special case of traveling salesman problem ([4]; [5]; [45]).

Order picking systems may be classified into three main categories: picker to goods, goods to picker, and automated systems ([2]; [4]; [11]; [38]; [43]; [54]; [65]; [70]).

Table 6 exhibits the models encountered in the literature review and how the decisions about order picking were covered.

Table 6. Order picking models

Source: Authors

4.6 Cross Docking

Cross docking is the process of transferring goods directly from the receiving to the expedition areas, which requires a high level of coordination to ensure that these operations can be problem free ([42]; [44]; [65]). It is an operational strategy that can reduce costs and improve warehouse efficiency by reducing inbound materials’ movement ([37]).

The obvious candidates for cross docking are those products that have already been ordered by the final customer. Other possibilities are products that require prompt delivery or high-demand products with predictable demand ([42]).

4.6.1 Allocating resources

Resources, such as labor and equipment, are important factors in planning a system of logistical support, as it is the case of warehousing installations ([17]; [62]). Material movement activities demand well-designed internal transport systems that may reduce the associated operational costs ([3]).

Automated systems include: automated stocking systems (AS); automated replacement systems (RS); picking by voice; and triage systems. An AS or RS is a totally automated system that ordinarily includes the following components: stock supports (SR), stocking equipment and servicing (S/R machines), an entrance and an exit (I/P), and local transporters ([8]; [23]; [35]; [61]; [65]). Article [8] includes a framework for designing AS/RS systems as their use has advantages over non-automated systems.

Among such advantage, such as: labor and space cost savings; greater reliability; better space utilization; and reduced error rates. The apparent disadvantages are high investment costs, less flexibility, and greater investment in control systems ([8]; [25]; [35]).

4.6.2 Information and control technology

An in-depth understanding of the content of goods that are received and expedited is becoming more common as a result of advanced IT, such as radio-frequency identification (RFID), global positioning system (GPS), electronic data interchange (EDI), and advanced shipping notices (ASN) ([5]; [24]; [31]; [37]; [65]; [66]).

The main technology in regard to warehousing is WMS ([2]; [6]; [11]; [17]; [38]), which is a database of applications, that controls inventory efficiency, keeping it at the exact level for the needs and registry (registration) of an operation ([38]).

4.6.3 Performance and monitoring indicators

The performance evaluation metric most commonly employed in warehouse design is the internal distance run ([4]). The two types of distance that are amply (currently) utilized in the order picking literature are the average picking run distance (or average length) and the total run distance ([4]; [8]; [10]; [19]; [54]).

A very common metric is the total processing time for one order, that is given by the sum of the picking trip time and stopping for accessing to the SKU ([9]; [25]; [58]; [59]). The difference between distance and travel time is in the speed of vertical and horizontal movements that do not have the same proportion ([21]).

Other performance criteria are: use of space; equipment use; manual labor utilization; item accessibility; order fulfillment accuracy; stocking waiting time; working hours; waiting time for picking an entire (or a complete) lot; lateness number; or a combination of these ([4]; [6]; [8]; [17]; [21]; [29]; [36]; [38]; [52]; [58]; [59]).

4.6.4 Outputs

With the implementation or redesign of a warehouse, the plan is to maximize the service level subject to resource restrictions or, in a dual form, minimize design costs subject to restrictions in service levels ([4]; [11]; [15]; [62]; [71]).

Service level is composed by a variety of performance metrics, such as order processing rate, average and variations in delivery time, integrity, and order precision. The faster an order is put together, the sooner it will be ready to be shipped to the client ([11]). Furthermore, short order picking times imply high flexibility to deal with order alterations (modifications) ([4]; [1]; [41]; [53]).

In article [6] the objective is to understand how to minimize the costs of order picking, considering labor, equipment and triage systems, attending the requirements of order processing rates, considering factors such as blockage of order pickers and unbalancing of the work force, which could affect the service level. Article [12] adds the cost of stocking space to the functional objective. On the other hand, in articles [9] and [19] the objective is to minimize the order processing rate ([9]) and meet anticipated demand ([19]).

5. Final considerations

This study presented a systematic review of the literature about warehouse design from 1999 to 2015, which was analyzed based on a framework containing the groups of the most relevant decisions within the scope of the design and implementation of warehouse installations.

It was stated that the majority (48%) of the studies analyzed are theoretical and quantitative. There are still few articles that have a valid model applicable to real cases which identify the points of major difficulty during a successful warehouse installation.

About operations strategies, it is observed that there are a reduced number of publications dealing directly with receiving and/or expedition, at a strategic level, such as decisions about dock layout, or on operational level, looking at the allocation of trucks on the docks. The same thing is occurring with cross-docking activities. Therefore, future studies of this theme are suggested.

Layout decisions strongly influence operational strategies, and the sub-problem most covered was the general layout, which deals with questions of aisle dimensions and physical arrangement of activities, in order to reduce the internal distance run.

Thanks to the generalized implementation of new IT developments that offer fresh opportunities for improving warehouse operations, this interactivity between activities and decisions is feasible. Featured among them are real-time control of warehouse functions, easy communications with other parts of the supply chain and high levels of automation.

Concerning design decisions in the supply chain, the review shows that they are divided into three groups: strategic; tactical; and operational. On the strategic level, they consist of network configuration decisions, such as the number of installations/knots, the location of these knots, and the capacity and technology to be implanted in each installation. In this context, the decisions about warehouse design are made. The tactical level, relates to network connectivity decisions, and at the operational level, lie the production decisions.

In regard to automation capacity, the topic about allocating resources covers the problem of equipment selection, and the definition in terms of which materials should be employed for handling equipment systems. Many studies on automated systems were encountered but quite few with manual movement optimization models. Only one article dealt with the question through the lens of a trade-off between the use of the human factor and the automation level. Given the importance of this theme, it is also suggested as a subject to be further explored in future studies.

The product variety to be moved by the warehouse was the most commented characteristic. Since the greater the variety, the more flexible the installation must be to deal with the multiplicity, the more complex the installation design becomes. Regarding this input on the framework, it should be pointed out that there are other important characteristics, which could have a great impact on the general configuration of a warehouse but have not as yet been treated in any model. The review presented here did not cover them, and it is hoped that future research can include them, such as: categorization of an item into a family and/or class, physical characteristics, weight, packaging, and public regulations.

Regarding financial factors, operational costs are included in the majority of the models analyzed. Note the lack of models that consider the question of investment, of which there are important indices of implementation of an installation that will require an amount so significant as the case of a warehouse. With reference to operational factors, the most considered models were distance run and processing rate. These factors are associated with order picking activities, which are emerging today as the main activity in distribution centers.

Finally, the main objectives of designing warehouse installations are: minimizing costs; and maximizing the order processing rate. There were no articles encountered that looked to minimize investments or maximize profits, as well as minimizing delays in product delivery, an important point in the context of service level.

Although the articles selected represent a significant sample of literature on the theme, it is important to point out the limitations of the study. It is concentrated basically on articles indexed in Science Direct and uses the search parameters laid out in the method description.

References

Agatz, N. A. H. et al. (2008), “E-fulfillment and multi channel distribution – A review”, European Journal of Operational Research, Vol. 187, No. 2, pp. 339-356.

Amiri, A. (2002), “An integrated approach for planning the adoption of client/server systems”, European Journal of Operational Research, Vol. 142, No. 3, pp. 509-522.

Amiri, A. (2006), “Designing a distribution network in a supply chain system: Formulation and efficient solution procedure”, European Journal of Operational Research, Vol. 171, No. 2, pp. 567-576.

Azzi, A. et al. (2011), “Innovative travel time model for dual-shuttle automated storage/retrieval systems”, Computers & Industrial Engineering, Vol. 61, No. 3, pp. 600-607.

Badri, M. A. (1999), “Combining the analytic hierarchy process and goal programming for global facility location-allocation problem”, International Journal of Production Economics, Vol. 62, No. 3, pp. 237-248.

Baker, P. (2004), “Aligning Distribution Center Operations to Supply Chain Strategy”, The International Journal of Logistics Management, Vol. 15, No. 1, pp. 111-123.

Baker, P., Canessa, M. (2009), “Warehouse design: A structured approach”, European Journal of Operational Research, Vol. 193, No. 2, pp. 425-436.

Beamon, B. M. (1999), “System reliability and congestion in a material handling system”, Computers & Industrial Engineering, Vol. 36, No. 3, pp. 673-684.

Bidhandi, H. et al. (2009), “Development of a new approach for deterministic supply chain network design”, European Journal of Operational Research, Vol. 198, No. 1, pp. 121-128.

Carter, C. R., Easton, P. L. (2011), “Sustainable supply chain management: evolution and future directions”, International Journal of Physical Distribution & Logistics Management, Vol. 41, No. 1, pp. 46-62.

Chakravorty, S. (2009), “Improving distribution operations: Implementation of material handling systems”, International Journal of Production Economics, Vol. 122, No. 1, pp. 89-106.

Chan, F. T. S., Chan, H. K. (2001), “Improving the productivity of order picking of a manual-pick and multi-level rack distribution warehouse through the implementation of class-based storage”, Expert Systems with Applications, Vol. 38, No. 3, pp. 2686-2700.

Chen, C. (2001), “A fuzzy approach to select the location of the distribution center”, Fuzzy Sets and Systems, Vol. 118, No. 1, pp. 65-73.

Chen, L. et al. (2011), “A tabu search algorithm for the relocation problem in a warehousing system”, International Journal of Production Economics, Vol. 129, No. 1, pp. 147-156.

Chen, M. C. et al. (2005), Aggregation of orders in distribution centers using data mining, Expert Systems with Applications, Vol. 28, No. 3, pp. 453-460.

Chow, H. K. H. et al. (2005), “Design of a knowledge-based logistics strategy system”, Expert Systems with Applications, Vol. 29, No. 2, pp. 272-290.

Cordeau, J. F. et al. (2006), An integrated model for logistics network design, Annals of Operations Research, Vol. 144, No. 1, pp. 59-82.

Costa, N. N. (2012), Design de Armazéns: uma revisão sistemática da literatura, Master’s Degree Dissertation, Pontifícia Universidade Católica do Rio de Janeiro.

Daly, S. P., Cui, L. X. (2003), “E-logistics in China: basic problems, manageable concerns and intractable solutions”, Industrial Marketing Management, Vol. 32, No. 3, pp. 235-242.

Dasci, A., Verter, V. (2001), “A continuous model for production-distribution system design”, European Journal of Operational Research, Vol. 129, No. 2, pp. 287-298.

Demirel, T. et al. (2010), “Multi-criteria warehouse location selection using Choquet integral”, Expert Systems with Applications, Vol. 37, No. 5, pp. 3943-3952.

Denk, N. et al. (2012), “Increasing the rigor of grounded theory research – a review of the SCM literature”, International Journal of Physical Distribution & Logistics Management, Vol. 42, No. 8/9, pp. 742-763.

Gagliardi, J. et al. (2008), “Space allocation and stock replenishment synchronization in a distribution center”, International Journal Production Economics, Vol. 115, No. 1, pp. 19-27.

Gill, A. (2009), “Determining loading dock requirements in production-distribution facilities under uncertainty”, Computers & Industrial Engineering, Vol. 57, No. 1, pp. 161-168.

Gligor, D. M., Holcomb, M. C. (2012), “Understanding the role of logistics capabilities in achieving supply chain agility: a systematic literature review”, Supply Chain Management: An International Journal, Vol. 17, No. 4, pp. 438-453.

Gu, J. et al. (2007), “Research on Warehouse Operation: A Comprehensive Review”, European Journal of Operational Research, Vol. 177, No. 1, pp. 1-21.

Gu, J. et al. (2010), “Research on warehouse design and performance evaluation: A comprehensive review”, European Journal of Operational Research, Vol. 203, No. 3, pp. 539-549.

Hackman, S. T. et al. (2001), “Benchmarking Warehousing and Distribution Operations: An Input-Output Approach”, Journal of Productivity Analysis, Vol. 16, No. 1, pp. 79-100.

Hammami, R. et al. (2008), “Supply chain design in the delocalization context: Relevant features and new modeling tendencies”, International Journal of Production Economics, Vol. 113, No. 2, pp. 641-656.

Ho, Y. et al. (2008), “Order-batching methods for an order-picking warehouse with two cross aisles”, Computers & Industrial Engineering, Vol. 55, No. 2, pp. 321-347.

Hsu, C. et al. (2005), “Batching orders in warehouses by minimizing travel distance with genetic algorithms”, Computers in Industry, Vol. 56, No. 2, pp. 169-178.

Hwang, H. S. (2004), “A stochastic set-covering location model for both ameliorating and deteriorating items”, Computers & Industrial Engineering, Vol. 46, No. 2, pp. 313-319.

Hwang, H. S., Cho, G. S. (2006), “A performance evaluation model for order picking warehouse design”, Computers & Industrial Engineering, Vol. 51, No. 2, pp. 335-342.

Jayaraman, V., Ross, A. (2003), “A simulated annealing methodology to distribution network design and management”, European Journal of Operational Research, Vol. 144, No. 3, pp. 629-645.

Johnson, A. et al. (2010), “Large-scale Internet benchmarking: Technology and application in warehousing operations”, Computers in Industry, Vol. 61, No. 3, pp. 280-286.

Khan, K. et al. (2001), Undertaking Systematic Reviews of Research on Effectiveness: CRD’s Guidance for those Carrying Out or Comissioning Reviews, NHS Centre for Reviews and Dissemination, University of York, York, UK.

Kirca, A. H., Yaprak, A. (2010), “The use of meta-analysis in international business research: Its current status and suggestions for better practice”, International Business Review, Vol. 19, No. 3, pp. 306-314.

Klose, A., Drexl, A. (2005), “Facility location models for distribution system design”, European Journal of Operational Research, Vol. 162, No. 1, pp. 4-29.

Koster, R. et al. (2007), “Design and Control of Warehouse Order Picking: A Literature Review”, European Journal of Operational Research, Vol. 182, No. 2, pp. 481-501.

Lai, K. K. et al. (2002), “Layout design for a paper reel warehouse: A two-stage heuristic approach”, International Journal of Production Economics, Vol. 75, No. 3, pp. 231-243.

Lam, C. H. et al. (2012), “A hybrid case-GA-based decision support model for warehouse operation in fulfilling cross-border orders”, Expert Systems with Applications, Vol. 39, No. 8, pp. 7015-7028.

Lambert, D. M., Cooper, M. C. (2000), “Issues in supply chain management”, Industrial Marketing Management, Vol. 29, No. 1, pp. 65-83.

Le-Anh, T., Koster, M. B. M. (2006), “A review of design and control of automated guided vehicle systems”, European Journal of Operational Research, Vol. 171, No. 1, pp. 1-23.

Le-Duc, T., Koster, R. (2007), “Travel time estimation and order batching in a 2-block warehouse”, European Journal of Operational Research, Vol. 176, No. 1, pp. 374-388.

Lee, J. M., Lee, Y. H. (2010), “Tabu based heuristics for the generalized hierarchical covering location problem”, Computers & Industrial Engineering, Vol. 58, No. 4, pp. 638-645.

Lerher, T. et al. (2010), “Travel time models for automated warehouses with aisle transferring storage and retrieval machine”, European Journal of Operational Research, Vol. 205, No. 3, pp. 571-583.

Li, T. S., Cavusgil, T. (1995), “A classification and assessment of research streams in International Marketing”, International Business Review, Vol. 4, No. 3, pp. 251-277.

Li, T., Wang, Z. (2008), “Application of Plant Growth Simulation Algorithm on Solving Facility Location Problem”, Systems Engineering - Theory & Practice, Vol. 28, No. 12, pp. 107-155.

Li, Y. et al. (2011), “Selection of logistics center location using Axiomatic Fuzzy Set and TOPSIS methodology in logistics management”, Expert Systems with Applications, Vol. 38, No. 6, pp. 7901-7908.

Liggett, R. S. (2000), “Automated facilities layout: past, present and future”, Automation in Construction, Vol. 9, No. 2, pp. 197-215.

Malmborg, C. J. & Al-Tassan, K. (2000). An integrated performance model for order picking systems with randomized storage. Applied Mathematical Modelling, 24 (2), 95-111.

Mason, S. J. et al. (2003), “Integrating the warehousing and transportation functions of the supply chain”, Transportation Research Part E, Vol. 39, No. 2, pp. 141-159.

Melachrinoudis, E., Min, H. (2007), “Redesigning a warehouse network”, European Journal of Operational Research, Vol. 176, No. 1, pp. 210-229.

Miranda, P., Garrido, R. (2004), “Incorporating inventory control decisions into a strategic distribution network design model with stochastic demand”, Transportation Research Part E, Vol. 40, No. 3, pp. 183-207.

Miranda, P., Garrido, R. (2009), “Inventory service-level optimization within distribution network design problem”, International Journal Production Economics, Vol. 122, No. 1, pp. 276-285.

Mishra, N. et al. (2011), “Addressing lot sizing and warehousing scheduling problem in manufacturing environment”, Expert Systems with Applications, Vol. 38, No. 9, pp. 11751-11762.

Muppani, V. R., Adil, G. K. (2008), “A branch and bound algorithm for class based storage location assignment”, European Journal of Operational Research, Vol. 189, No. 2, pp. 492-507.

Muppani, V. R., Adil, G. K. (2008), “Efficient formation of storage classes for warehouse storage location assignment: A simulated annealing approach”, Omega, Vol. 36, No. 4, pp. 609-618.

Naraharisetti, P. K. et al. (2008), “Supply chain redesign through optimal asset management and capital budgeting”, Computers and Chemical Engineering, Vol. 32, No. 12, pp. 3153-3169.

Ngai, E. W. T. et al. (2008), “RFID research: An academic literature review (1995–2005) and future research directions”, International Journal of Production Economics, Vol. 112, No. 2, pp. 510-520.

Ngai, E. W. T. et al. (2011), “The application of data mining techniques in financial fraud detection: A classification framework and an academic review of literature”, Decision Support Systems, Vol. 50, No. 3, pp. 559-569.

O'Donnell, E., David, J. S. (2000), “How information systems influence user decisions: a research framework and literature review”, International Journal of Accounting Information Systems, Vol. 1, No. 3, pp. 178-203.

Önüt, S. et al. (2008), “A particle swarm optimization algorithm for the multiple-level warehouse layout design problem”, Computers & Industrial Engineering, Vol. 54, No. 4, pp. 783-799.

Öztürkoğlu, Ö. et al (2014), “A constructive aisle design model for unit-load warehouses with multiple pickup and deposit points”, European Journal of Operational Research, Vol. 236, No. 1, pp. 382-394.

Pan, J. C. H. et al. (2014), “A travel time estimation model for a high-level picker-to-part system with class-based storage policies”, European Journal of Operational Research, Vol. 237, No. 3, pp. 1054-1066.

Pan, J., Shih, P. (2008), “Evaluation of the throughput of a multiple-picker order picking system with congestion consideration”, Computers & Industrial Engineering, Vol. 55, No. 2, pp. 379-389.

Papageorgiou, L. G. (2009), “Supply chain optimisation for the process industries: Advances and opportunities”, Computers and Chemical Engineering, Vol. 33, No. 12, pp. 1931-1938.

Parikh, P. J., Meller, R. D. (2008), “Selecting between batch and zone order picking strategies in a distribution center’, Transportation Research Part E, Vol. 44, No. 5, pp. 696-719.

Parikh, P. J., Meller, R. D. (2010), “A travel-time model for a person-onboard order picking system”, European Journal of Operational Research, Vol. 200, No. 2, pp. 385-394.

Pedreira, L. N. (2006), Proposta para um sistema de controle de armazéns (WCS) com aplicação em uma empresa de pequeno porte, Master’s Degree Dissertation, Pontifícia Universidade Católica do Rio de Janeiro.

Pilbeam, C. et al. (2012), “The governance of supply networks: a systematic literature review”, Supply Chain Management: an International Journal, Vol. 17, No. 4, pp. 358-376.

Pohl, L. M. et al. (2009), “An analysis of dual-command operations in common warehouse designs”, Transportation Research Part E, Vol. 45, No. 3, pp. 367-379.

Reis, A. C. et al. (2013), “Product variety management: A synthesis of existing research”, African Journal of Business Management, Vol. 7, No. 1, pp. 39-55.

Rodrigues, G. G. (2003), Um estudo sobre a logística reversa dos produtos de pós venda nos centros de distribuição de lojas de departamento, Master’s Degree Dissertation, Pontifícia Universidade Católica do Rio de Janeiro.

Rodriguez, V. et al. (2007), “Hub location under capacity constraints”, Transportation Research Part E, Vol. 43, No. 5, pp. 495-505.

Roodbergen, K. J., Vis, I. F. A. (2009), “A survey of literature on automated storage and retrieval systems”, European Journal of Operational Research, Vol. 194, No. 2, pp. 343-362.

Rouwenhorst, B. et al. (2000), “Warehouse Design and Control: Framework and Literature Review”, European Journal of Operational Research, Vol. 122, No. 3, pp. 515-533.

Rubrico, J. et al. (2011), “Online rescheduling of multiple picking agents for warehouse management”, Robotics and Computer-Integrated Manufacturing, Vol. 27, No. 1, pp. 62-71.

Santoso, T. et al. (2005), “A stochastic programming approach for supply chain network design under uncertainty”, European Journal of Operational Research, Vol, 167, No. 1, pp. 96-115.

Seurin, S., Gold, S. (2012), “Conducting content-analysis based literature reviews in supply chain management”, Supply Chain Management: an International Journal, Vol. 17, No. 5, pp. 544-555.

Sohn, S. Y. et al. (2007), “Development of an Air Force Warehouse Logistics Index to continuously improve logistics capabilities” European Journal of Operational Research, Vol. 183, No. 1, pp. 148-161.

Strack, G., Pochet, Y. (2010), “An integrated model for warehouse and inventory planning”, European Journal of Operational Research, Vol. 204, No. 1, pp. 35-50.

Theys, C. et al. (2010), “Using a TSP heuristic for routing order pickers in warehouses”, European Journal of Operational Research, Vol. 200, No. 3, pp. 755-763.

Tjahjono, B. et al. (2010), “Six Sigma: a literature review”, International Journal of Lean Six Sigma, Vol. 1, No. 3, pp. 216-233.

Tompkins, J. A. et al. (1996), Facilities Planning, 2th ed., Jonh Willey, New York.

Tseng, T. Y. et al. (2008), “How to use a systematic literature review and meta-analysis”, The Journal of Urology, Vol. 180, No. 4, pp. 1249-1256.

Van den Berg, J. P. (1999), “A Literature Survey on Planning and control of Warehouse Systems”, IIE Transactions, Vol. 31, No. 8, pp. 751-762.

Van Utterbeeck, F. et al. (2009), “The effects of resupply flexibility on the design of service parts supply systems”, Transportation Research Part E, Vol. 45, No. 1, pp. 72-85.

Van Zelst, S. et al. (2009), “Logistics drivers for shelf stacking in grocery retail stores: Potential for efficiency improvement”, International Journal of Production Economics, Vol. 121, No. 2, pp. 620-632.

Ventura, J. A., Lee, C. (2001), “A Study of the Tandem Loop with Multiple Vehicles Configuration for Automated Guided Vehicle Systems”, Journal of Manufacturing Systems, Vol. 20, No. 3, pp. 153-165.

Ventura, J. A., Rieksts, B. Q. (2009), “Optimal location of dwell points in a single loop AGV system with time restrictions on vehicle availability”, European Journal of Operational Research, Vol. 192, No. 1, pp. 93-104.

Vis, I., Roodbergen, K. (2011), “Layout and control policies for cross docking operations”, Computers & Industrial Engineering, Vol. 61, No. 4, pp. 911-919.

Vrijhoef, R., Koskela, L. (2000), “The four roles of supply chain management in construction”, European Journal of Purchasing & Supply Management, Vol. 6, No. 3-4, pp. 169-178.

Werner, B., Wülfing, T. (2010), “Robust optimization of internal transports at a parcel sorting center operated by Deutsche Post World Net”, European Journal of Operational Research, Vol. 201, No. 2, pp. 419-426.

Winter, M., Knemeyer, A. M. (2013), “Exploring the integration of sustainability and supply chain management – Current state and opportunities for future inquiry”, International Journal of Physical Distribution & Logistics Management, Vol. 43, No. 1, pp. 18-38.

Wong, C. et al. (2012), “Towards a theory of supply chain alignment enablers: a systematic literature review”, Supply Chain Management: an International Journal, Vol. 17, No. 4, pp. 419-437.

Yang, W. et al. (2011), “Optimizing replenishment polices using Genetic Algorithm for single-warehouse multi-retailer system”, Expert Systems with Applications, Vol. 39, No. 3, pp. 3081-3086.

Yang, Z. et al. (2006), “A review of research methodologies in international business”, International Business Review, Vol. 15, No. 6, pp. 601-6017.

Yu, M., Koster, R. B. M. (2009), “The impact of order batching and picking area zoning on order picking system performance”, European Journal of Operational Research, Vol. 198, No. 2, pp. 480-490.