Integration of concepts about lean construction, sustainability and life cycle of buildings: a literature review

Alberto Eduardo Besser Freitag1, Rosley Anholon2, Valmir Martins de Oliveira3, Tomás Vivanco Larrain4

1 Fluminense Federal University – UFF

2 University of Campinas – UNICAMP

3 Universidad Autónoma de Chile

4 Pontifical Catholic University of Chile

Abstract

The purpose of this study was the development of a theoretical framework integrating concepts of lean construction, sustainability and the life cycle of buildings. It was prepared using a systematic review of the literature through the Prisma method. Findings show that there is scarce scientific literature about lean construction contributions to activities related to the consumption phase of the life cycle of a building. Project and construction activities presented the highest number of lean construction contributions in the production phase. Research limitations are terms used in the search sentences and the choice of surveyed databases. The study contributes with knowledge that can be used by companies to adopt lean construction. It is also useful for researchers who can explore several research lines. The originality of this research is to view in a same table the interrelationship of concepts about lean construction, sustainability and the life cycle of buildings.

Keywords: Lean management, Construction industry, Sustainability, Life cycle, Brazil.

1. Introduction

The construction industry is one of the economic indicators of success in the prosperity of a nation, since this sector has a substantial impact on Gross Domestic Product (GDP) and employment (Ibrahim et al., 2010). The authors reported that a 10% increase in the productivity of this sector would result in a GDP improvement estimated in 2.5 %, since the performance of the construction industry affects productivity in all sectors of the economy.

Brazil’s development and production capacity are directly related to the growth of the construction industry. This implies new challenges for innovation, technology, professional training and the establishment of business environments that promote productivity, business competitiveness and country development (FIRJAN, 2014).

An explanation for the persistent differences in productivity between companies, and between the respective countries where they are located, lies largely on variations of management practices (Bloom et Rennen, 2010). To measure management practices, the authors developed a research methodology and conducted almost 6,000 interviews, using a random sample of the population of all public and private manufacturing companies with 100 to 5,000 employees.

The United States has, on average, the highest scores for management practices, followed by Germany, Japan, Sweden and Canada and then followed by a block of Central European countries - France, Italy, Ireland, the UK and Poland - and Australia. The last places belong to southern European countries, such as Greece and Portugal, along with developing countries such as Brazil, China and India. Bloom et Reenen (2010) found that energy efficiency is strongly associated with a higher level of company management, probably because good management practices, such as lean manufacturing, tend to save on energy consumption.

Many studies have been published on the application of lean manufacturing practices and continuous improvement concepts in different sectors, such as healthcare (Senna et al., 2016; Ferreira et al., 2016; Paim et al., 2016; Maruyama et al., 2016), paper packaging industry (Hidalgo Martins et Cleto, 2016), construction (Nascimento et al., 2016; Martins et al., 2016), automobile industry (Vanalle et al., 2009), sugar and ethanol industry (Satolo et al., 2012), food (Endo et al., 2017) and beverage plants (Araujo et Castro, 2012).

EY and the engineering department of the Polytechnic School of the University of São Paulo (USP) developed a study (EY, 2014) about productivity in the construction industry. Personal interviews were conducted in eight companies and an online questionnaire was answered by 74 executives working in the sector in Brazil. Seven productivity levers were defined for the study, of which project planning and management methods such as lean construction - construction based on waste reduction paradigms that became known as the Toyota production method - will be prioritized in 2015-2016, according to the interviewed professionals.

Productivity and innovation have a direct relation with sustainability. The search for competitiveness and sustainability should influence the actions and positions of Brazilian industrial companies and other representative bodies, both industrial and governmental, as well as other organizations directly or indirectly related to the industrial issue (CNI, 2013).

According to the ISO 26000:2010 standards (ABNT, 2010), the goal of sustainable development is to achieve a state of sustainability for society as a whole and for the planet. The sustainability of an organization may or may not be compatible with the sustainability of society as a whole, which is obtained when dealing with social, economic and environmental aspects in an integrated manner, as mentioned in the classic work of Elkington (1998) on the Triple Bottom Line. Sustainable consumption, sustainable resource use and sustainable livelihoods are relevant to all organizations and are related to society’s sustainability as a whole.

Martínez-Jurado et Moyano-Fuentes (2014) analyzed 58 articles, representing the state-of-the-art research on the links between Lean Management, Supply Chain Management and Sustainability. About half of all studies have been conducted in the automotive sector and 17% of published papers dealt, simultaneously, with different sectors such as chemical, electronic, construction with wood, agro-food and financial, among others. Most studies in specific sectors were not significant enough to be analyzed individually, such as the construction industry.

This context demonstrates the importance of the construction industry value chain for the world economy, and the need for Brazilian companies to adopt management methods to increase productivity, such as lean construction, respecting sustainability criteria. Analyzing the existing literature, an opportunity is observed to develop research to identify the interrelationships between lean construction, sustainability and the life cycle of a building. Thus, the study proposed herein complements the findings of the aforementioned documents, aiming to answer the following research question: "How to integrate concepts of lean construction, sustainability and the life cycle of a building?"

This question is expected to be answered by developing a theoretical framework integrating concepts of lean construction, sustainability and the life cycle of a building, which is the main objective of this study. The specific objectives are the detailing of activities related to the production and consumption phases of the life cycle of a building, based on existing literature and identifying the contributions of lean construction for sustainability in its economic, social and environmental dimensions, based on state-of-the art literature.

This first section contains the context that led to the development of this paper; the second section presents the material collected using a systematic review of the literature as the research method, involving phases, steps and activities of the life cycle of a building and lean construction contributions towards sustainability; the third section presents the expected results for the objectives of this study and their discussion; while the fourth section presents the conclusions.

2. Material and methods

The material for this paper was collected through a systematic literature review, conducted in four steps. First, a set of records resulting from the search sentences used at SciELO and Scopus scientific databases was identified. Then, a second set was selected, consisting of items that remained after the removal of duplicated and non-adherent records, as well as those with incomplete author information. At the final steps, a content analysis of the remaining documents was conducted in order to select those to be included in the literature review.

Initially the material used in preparing this study will be presented, encompassing existing scientific literature about phases, steps and activities of a building life cycle as well as contributions of lean construction for sustainability. Subsequently, the research method adopted in the present study will be detailed.

2.1 Material

2.1.1 Phases, steps and activities in the life cycle of a building from the construction industry

Life analysis is a methodology that attempts to identify, quantify and characterize the different potential environmental impacts associated with each step of the useful life of a product (Calcedo et al., 2012). The authors compared a masonry structure with a reinforced concrete structure, using the Life Cycle Analysis by applying the ISO 14040 and ISO 14044 standards, dividing the life of each of the materials that compose the structures into five steps:

-

The manufacturing, which includes the extraction of raw materials and the manufacturing process;

-

The delivery of the material to the consumption point;

-

The effort of putting the resources used in the construction process;

-

The useful life of the used resources; and

-

Demolition and recycling.

Passuello et al. (2014), discuss the BRE 15804 standard, which evaluates the environmental performance of products related to the construction industry, through environmental EPD labeling (Environmental Product Declaration), according to which five phases of the life cycle of buildings can be identified:

-

Product selection;

-

Construction;

-

Use;

-

End of life; and

-

Benefits and environmental loads.

In the same study, the authors listed the four steps of the Life Cycle Assessment, according to the NBR/ISO 14040 standard:

-

Definition of goal and scope;

-

Inventory analysis;

-

Impact assessment; and

-

Interpretation.

The concept of a construction system life cycle was considered in the research of Ortiz-Rodriguez et al. (2012), with the two phases described below, displaying materials, water and energy as inputs and solid waste, together with air, land and water emissions as outputs:

-

Construction, including the extraction and production of construction materials and transportation to the construction site;

-

Use, including operation and maintenance.

Muñoz et al. (2012) considered a set of five unitary processes for the Life Cycle Assessment of a house:

-

Extraction of raw materials;

-

Transport and distribution;

-

Construction involving CO2 emissions and consumption of energy and fuel;

-

Use or operation; and

-

Demolition.

The development of the integrated approach of Sustainable Construction and Lean Construction philosophies should be analyzed within the life cycle of a project, according to Martínez et al. (2009). Their research includes the steps of Design - Planning - Construction, and exclude Operation and Deconstruction steps, thus the entire Productive Cycle or Materialization of a construction project is taken into account. Other research phases will address the exploration or use (operation) steps and end of its useful life, with this being the final step, where reuse or recycling of each of the construction parts or components (deconstruction) should be considered. For the purpose of the analysis of the developed study, the considered steps were defined by the authors as:

-

Project: steps in which the engineering, construction and/or architecture drawings (in building projects) are developed, as well as the technical specifications and reference terms of the project are established for budget and planning. The types of relevant equipment and machinery are also defined.

-

Planning: steps in which project activities are programmed and the final work methods, layout, suppliers, inventory policies, acquisition programs for relevant equipment and machinery, quality and quantity of personnel and budget (among the most important elements of these steps), are defined.

-

Construction: steps in which the physical materialization of the project with all necessary material (labor, equipment, materials, etc.) and immaterial (drawings, inventory policy, working protocols, etc.) resources is accomplished.

Diaz et al. (2010) consider the Life Cycle Analysis as one of the most accurate methods of environmental assessment, focusing on the sustainability of products, processes and services. The evaluation of the environmental impacts of concrete manufacturing technologies is a complex process, since many elements are involved, combined in different operations and steps throughout their useful life. The development of each of the possible life cycle steps of the material was divided into eight steps, to facilitate the analysis of the study:

-

Extraction of raw materials;

-

Transportation of raw materials;

-

Production of concrete components;

-

Component distribution to plants and construction sites;

-

Drawings and/or projects;

-

Construction and start-up;

-

Use;

-

Demolition. Reuse. Rehabilitation.

The life cycle steps of hydro-sanitary equipment are addressed by Kalbusch et Ghisi (2012) as follows:

-

Production: extraction, processing and transportation of raw material, purchase, processing and transportation of recycled materials, equipment manufacturing (hydro-sanitary equipment industry), and equipment transportation;

-

Use: use and maintenance of the equipment;

-

Final provision: transportation, recycling and disposal.

Salgado et al. (2012) considered the life cycle of a building as divided into six steps:

-

Elaboration of the building program, which can be divided between environmental needs and project requirements (users);

-

Project development;

-

Definition of execution methods;

-

Implementation of the construction;

-

Use, operation and maintenance of the building; and

-

Demolition.

Sustainable construction, according to the authors, must meet the tripod that defines sustainability, including environmental, social and economic aspects, as follows:

-

Environmental: avoiding pollution, protectiing and improving biodiversity, improving energy efficiency and the efficient use of resources;

-

Social: respecting the staff, relationship with local communities and establishment of partnerships;

-

Economic: increasing productivity and profit, project improvement (product offered) and performance monitoring and reporting versus goals.

2.1.2 Contributions of lean construction for sustainability

The construction industry is continually evolving and moving forward with the use of new technologies, materials and practices. According to Harper et Hazleton (2014), for new, inexperienced, construction engineers to succeed in the construction industry, they need to be well educated in the main knowledge of construction and engineering, as well as understand how to use new technologies and practices, such as BIM (Building Information Modeling), sustainability and lean construction, effectively and efficiently. Sustainable construction requires almost the same basic knowledge than a traditional design, with differences in the details. These include changes in the materials and their procurement, innovations in lighting and energy, mechanical and air quality innovations, as well as sanitary and water use efficiency. Some of the advantages in using the principles of lean construction include lower project costs, fewer delays, less uncertainty, less waste, more efficient buildings and facilities and higher customer satisfaction. In addition, studies have shown that sustainability and lean construction complement each other in construction projects (Harper et Hazleton, 2014).

Lean construction is now faced with the challenges of sustainable development, continuous improvement, waste elimination, a stronger focus on the user, the need to increase the value for money coupled with high quality project management and improved supply chains and communications. Ogunbiyi et al. (2014) presented an exploratory study on existing literature and the results of the use of a questionnaire, among construction participants, to explore the contribution of lean construction techniques application in sustainable construction. A survey was conducted with UK based professionals, and the global perspective of building industry professionals, according to the questionnaire, shows that benefits due to the integration of lean construction principles and sustainable construction, within the construction industry, are perceived. The improvement of the corporate image was deemed the most important benefit to synchronize lean construction and sustainability, while increasing the morale and commitment of employees was the least important. Regarding the level of use of lean principles/techniques to enable sustainability in respondents’ organizations, just-in-time, visualization tools, value analysis, daily meetings and value stream mapping are the more common lean tools/techniques, while Six Sigma is the least used. The study of Ogunbiyi et al. (2014) also identified several connecting areas between lean construction and sustainability, the most important being waste reduction, environmental management, value maximization and health and safety improvement, among others, while cost reduction was indicated as being the least important.

Sustainability and lean concepts can be applied to the construction industry to help minimize waste. Although both concepts work to alleviate similar problems, organizations find it difficult to integrate the concepts. Koranda et al. (2012) examined projects of different sizes and in different environments in the Midwest of the United States to determine what aspects hinder the integration of sustainability and lean concepts in the region. Professionals related to the industry were surveyed to identify sources of waste in sustainable and lean projects. Based on case studies, various aspects of waste that exist in construction projects have been recognized, and a comparison of the interaction of lean concepts and sustainability has been documented. A model for the planning of the entire construction process was determined so that waste can be reduced and the integration of lean concepts and sustainability gets more feasible. In the model of Koranda et al. (2012), performance indicators are the essential condition for designers and contractors to be able to integrate lean and sustainability concepts. Observing the indicators, stakeholders can allow for a better understanding in terms of where they are in the process of integration of lean and sustainability concepts.

Construction activities and the built environment have a huge effect on the environment, human health and the economy in general. Sustainable home building in the three dimensions of economic, environmental and social effects is achievable through technology and practical innovation (Nahmens et Ikuma, 2012). However, the biggest barrier to the widespread application of sustainable home building is the higher initial cost, largely attributable to the employees’ learning curve, building with them practical innovations and technologies, and the resulting additional cost of bad defined construction processes. To meet these challenges and achieve the ideal of sustainable construction, the authors propose the use of lean construction as a viable and effective strategy, especially, the lean tool "kaizen". Nahmens et Ikuma (2012) use several case studies to demonstrate the lean effect on the triple bottom line of sustainability in the construction of modular homes. Each case study highlights a dimension of sustainability. Lean construction resulted in a significant environmental impact, reducing material waste by 64%, a significant social effect, reducing or eliminating the main security risks due to excessive force, poor posture and worker accidents, and a significant economic effect, reducing the production hours by 31%.

The lean manufacturing of autoclaved aerated concrete (AAC) is considered a highlight in the modern building materials industry (Boggelen, 2011). Crises, lower volume of construction, excess capacity and sustainability requirements have forced the construction industry to create higher product quality, greater efficiency and lower manufacturing costs with new application ideas. The reduction of waste and energy reuse is a serious potential for the AAC industry to contribute to a sustainable future. Based on a good fit between raw materials, technology and systems, lean manufacturing offers promising challenges for producers to reduce costs. According to Boggelen (2011), modern production technologies will support the AAC product development to achieve a better, faster, and, therefore, sustainable construction.

Construction companies are facing obstacles and challenges in the adoption of BIM (Building Information Modeling), since there is no clear guidance or study of best practices from which to learn and build their capacity to use BIM in order to increase productivity, efficiency, quality and achieve competitive advantages in the global market, thus reaching environmental sustainability goals. The study of Arayici et al. (2011) aims to conduct a comprehensive and systematic evaluation of technologies relevant to BIM, as part of the adoption and implementation of BIM, to demonstrate how efficiency gains have been achieved through a lean architectural practice. The overall BIM implementation approach used a socio-technical view that, not only considers the implementation of technology, but also considers the socio-cultural environment that provides the context for its implementation. As a result of BIM adoption, Arayici et al. (2011) reported efficiency gains achieved through pilot projects; and the design process of the project was improved through the elimination of waste and generation of value.

Many actors argue that the construction industry moves toward a lean output, based on a way of working through processes, for cost and quality reasons. In this context, engineering approaches using molded wood are considered competitive and environmentally advantageous. Tykkä et al. (2010) identified innovative companies in six European countries using molded wood and rated their sources of innovation. The common factor that leads these companies to innovate is that business opportunities arise from demographic changes in the environment outside the company, such as environmental sustainability and affordable housing for low-income groups. To address these opportunities, the companies used in the case studies implicitly acknowledged that the traditional approaches to design and construction on the building site are an incongruity. The companies, therefore, established internal prefabrication, including the development of methods based on lean production to ensure quality and effectiveness (Tykkä et al., 2010).

Currently, most engineering management approaches are concentrated in the outer world, that is, all what is visible (structures-processes-results). This situation has created low sustainability for these approaches and tools, since it overlooks central aspects of people’s individual and collective behavior. Based on this, various efforts are being carried out to integrate the inside and outside world of an organization, in order to draw the inside world (personality, affection, values, culture) as a space that facilitates the incorporation of effective management practices centered on the outside world, such as lean construction. Pavez et al. (2010) describe and analyze the theory of integral vision proposed by Wilber (2001, 2005, 2007), as a reference framework that allows strengthening the project management discipline, under the approach of lean construction.

2.2 Method

The purpose of the following described research method is to obtain knowledge available in the scientific literature to allow the development of a theoretical framework, integrating concepts of lean construction, sustainability and the life cycle of a building, according to the concept displayed in Figure 1.

Figure 1. Purpose of the research method

Source: The authors’ own.

A general strategy for conducting research is to use available data. In contrast to research strategies based on data, gathered first hand (experiments, surveys, field studies), data mining researchers make use of available second hand information. The source of such information includes data files generated from surveys and ethnographies (Singleton Jr. et Straits, 2010).

Systematic reviews are a specific way of identifying and synthesizing research evidence, with emphasis on (Robson, 2011):

-

Providing a comprehensive coverage of the available literature in the field of interest;

-

The quality of the evidence reviewed;

-

Following a detailed and explicit approach to the synthesis of the data; and

-

The use of transparent and rigorous processes throughout.

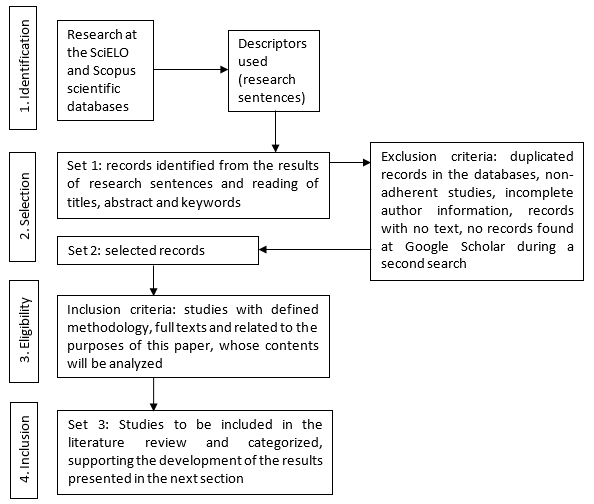

Based on this, a qualitative research approach was adopted, using available data whose content has been analyzed through the Prisma method (Preferred Reporting Items for Systematic Reviews and Meta-Analyses), a guide of recommendations for systematic reviews of the literature described by Moher et al. (2009), using the flow of information through four steps (identification, selection, eligibility and inclusion) described in Figure 2, from data available at the SciELO and Scopus scientific databases.

Figure 2. Flow of information through the four steps of a systematic review of the literature

Source: Compiled from Moher et al. (2009)

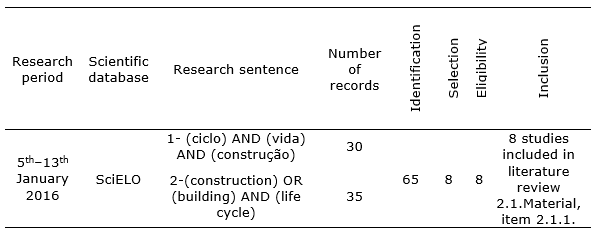

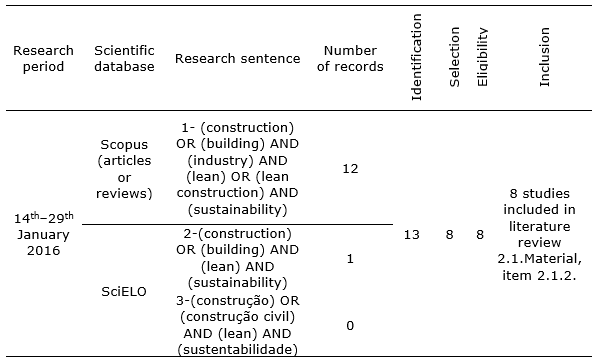

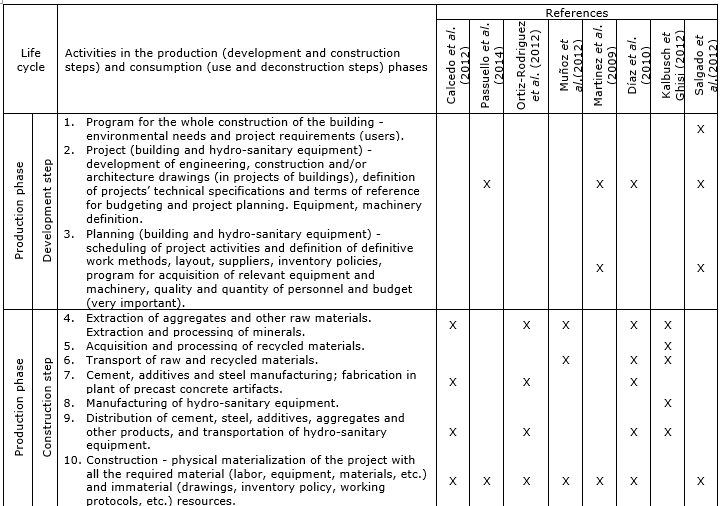

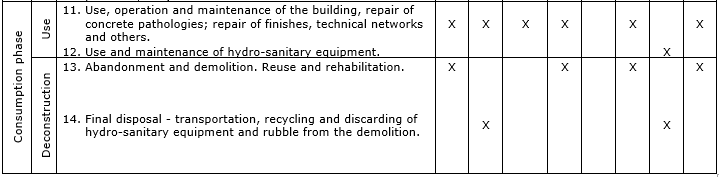

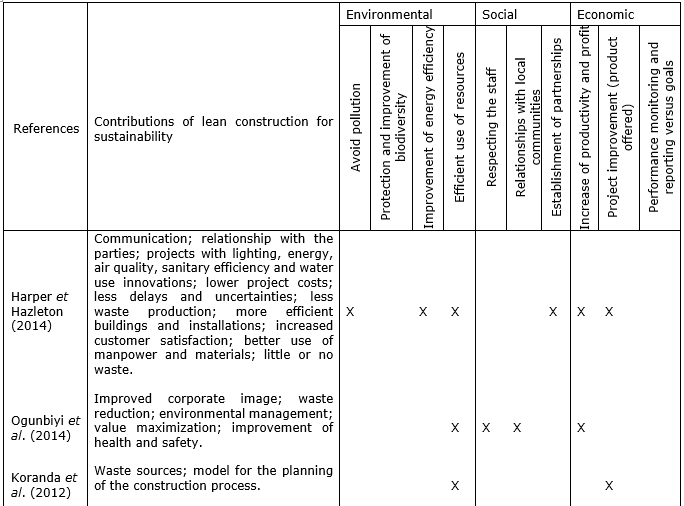

The research was conducted in two steps, the first dealing with the phases, steps and activities in the life cycle of construction industry buildings (Table 1), and the second about contributions of lean construction for sustainability (Table 2).

The SciELO scientific database was chosen in Table 1, especially to obtain available data from countries in South America about the life cycle of buildings.

Table 1. Research about phases, steps and activities related to the life cycle of buildings

Source: The authors’ own.

The Scopus scientific database is considered by Treinta et al. (2014) as being currently the largest database in view of the wide coverage of abstracts and literature citations it offers; Thus, it was accessed to obtain state-of-the-art knowledge about lean construction (Table 2). Considering that, after 2010, there is a leveling in the number of documents for the search sentence (construction) OR (building) AND (industry) AND (lean) OR (lean construction), that more than half of the records (163) are available from 2010 until January, 2016 and that this study was intended to be developed from recent literature, it was decided to limit the review from 2010 onwards.

Table 2. Research about contributions of lean construction for sustainability

Source: The authors’ own.

3. Results and discussion

The main result of this study is the development of a theoretical framework integrating concepts of lean construction, and sustainability and the life cycle of a building. To do this, the interrelationships between activities linked to the production and consumption phases of the life cycle of a building must be studied first, followed by the interrelationships of lean construction and economic, social and environmental sustainability.

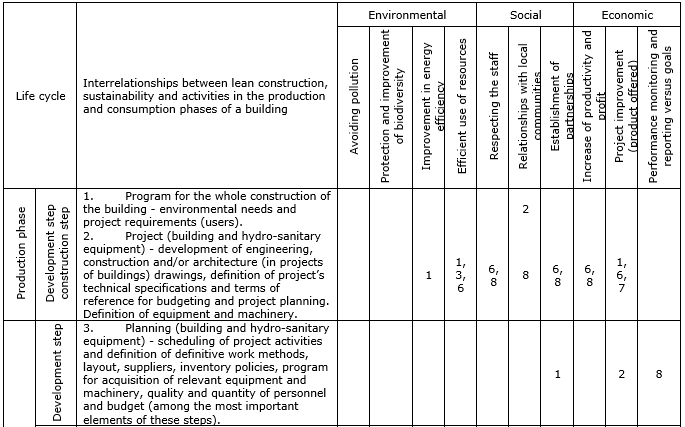

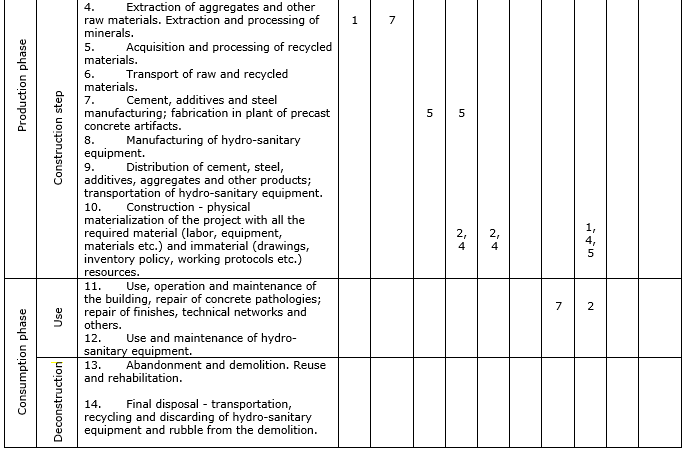

Analyzing the literature review of subsection 2.1.1., Phases, steps and activities in the life cycle of construction industry buildings, it can be realized that the eight documents addressed phases, steps and activities, ranging from two to eight. Table 3 displays the results of the consolidation of all 14 activities identified in the literature review, dividing the life cycle in two phases, each one with two steps. The first is the production phase, comprising the steps of development and construction, with a total of 10 activities. The second is the consumption phase, comprising the steps of use and deconstruction, with a total of four activities.

Activity 10 (construction) was the most frequently cited by the authors of the analyzed studies, followed by activity 11 (use, operation and maintenance) and activity 4 (extraction of aggregates and other raw materials). It is interesting to note the few studies available about life cycles of hydro-sanitary equipment (sinks, toilets, faucets, etc.), which are part of the life cycle of any building. Likewise, the existence of a program for the whole construction of the building (activity 1) was also relatively unexplored, despite its importance, because it influences, directly or indirectly, the 13 remaining activities in order to ensure an adequate life cycle, which meets the environmental and design needs, aiming to satisfy customers, users and society.

Table 3. Life cycle activities of production and consumption phases in buildings

Source: The authors’ own.

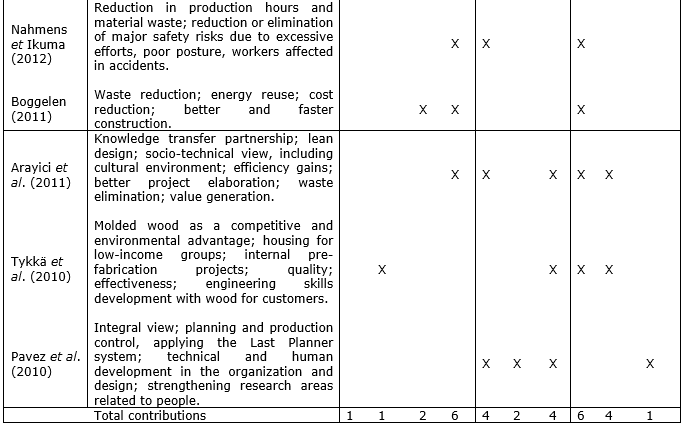

Analyzing the literature review of subsection 2.1.2., Contributions of lean construction for sustainability, it was possible to build Table 4, with the result of the consolidation of the main contributions of lean construction for sustainability, identified from the literature review, in alignment with the tripod that defines sustainability itself, including environmental, social and economic aspects and their sub-themes (Salgado et al., 2012).

Table 4. Contributions of lean construction for sustainability

Source: The authors’ own.

The results indicate that almost all authors address economic, social and environmental aspects in their studies. Only for two authors it was not possible to establish a direct relationship with social aspects (Koranda et al., 2012; Boggelen, 2011).

The environmental aspect had one of the most cited sub-themes, "efficient use of resources"; however, the other sub-themes merited little attention, which denotes research deepening opportunities in the sub-themes "avoid pollution," "protection and improvement of biodiversity" and "improvement of energy efficiency."

The social aspect was well quoted in the sub-themes "respect with staff" and "establishment of partnerships", but the sub-theme "relationship with local communities" can be further explored.

The economic aspect also had one of the most cited sub-themes, "increase of productivity and profit," obviously, very much in line with the precepts of the lean management philosophy. The sub-theme "project improvement (product offered)" was also mentioned several times. Strangely the subtheme “performance monitoring and reporting versus goals" received few contributions, indicating that its relationship for sustainability deserves attention in future research.

The theoretical framework, integrating concepts of lean construction, sustainability and the life cycle of a building in the construction industry (Table 5), was compiled from the 14 activities of the life cycle of a building, described in Table 3, and its relationship with the tripod, which defines sustainability, including environmental, social and economic aspects (Salgado et al., 2012), as well as the contributions of lean construction for sustainability, listed in Table 4.

The numbers presented in Table 5 are the references to the documents about lean construction with contributions for sustainability, and their more adherent alignment with the 14 activities of a building life cycle, as follows: (1) Harper et Hazleton, (2) Ogunbiyi et al., (3) Koranda et al., (4) Nahmens et Ikuma, (5) Boggelen, (6) Arayici et al., (7) Tykkä et al. and (8) Pavez et al.

Table 5. Theoretical framework integrating concepts of lean construction, sustainability and life cycle of a building.

Source: The authors’ own.

From the results, it was found that the vast majority of studies included in the literature review are about contributions of lean construction to the production phase, at the development and construction steps, from the life cycle of a building.

Regarding the development step, the life cycle activity 2 (project) received most lean construction contributions from the literature, especially in the sub-themes "efficient use of resources" of the environmental aspect and "project improvement (product offered)" from the economic aspect. As previously identified, activity 1 (program for the whole construction of the building), despite its importance, has been little explored so far, only with the sub-theme "relationship with local communities," from the social aspect. It is likely that there are research development opportunities also in connection with the contributions of environmental and economic aspects to this activity. Activity 3 (planning) also had few contributions, only the sub-theme "establishment of partnerships” of the social aspect and sub-themes "project improvement" and "performance monitoring and reporting versus goals" of the economic aspect. The importance of this activity is supported by the EY (2014) study, that identified this activity as one of the productivity levers that will be prioritized in 2015-2016 by the interviewed executives.

In the construction steps, the life cycle activity with more contributions received from lean construction was the actual construction activity (10), especially in the sub-theme "increase of productivity and profit" from the economic aspect. Activity 5 (acquisition and processing of recycled materials) and activity 8 (manufacturing of hydro-sanitary equipment) did not receive contributions from the surveyed studies, representing a further research development opportunity, especially for manufacturers of metals and ceramics. Similarly, there were no lean construction contributions for activities 6 (transportation of raw and recycled materials) and 9 (distribution of cement, steel, additives, aggregates and other products, and transportation of hydro-sanitary equipment.). These two activities have as core a logistical component, so they are also a research opportunity with good contribution prospects in the sub-theme "establishment of partnerships" from the social aspect, and "increase of productivity and profit" from the economic aspect.

There were virtually no contributions to the consumption phase, only two in activity 11 (use, operation and maintenance), at the use step. A comment is relevant at this step about the contribution to the sub-theme "establishment of partnerships", in the social aspect of sustainability, from the study of Tykkä et al. (2010), who identified, alongside the surveyed companies, that a key barrier to their business was the lack of engineering skills with molded wood in their customers' organizations. This led these companies to develop skills in construction projects with molded wood on their client teams, which include internal prefabrication through processes based on lean production to ensure quality and effectiveness.

Skill acquisition necessarily involves education, that is, learning lean construction concepts and tools in technical schools and universities, to ensure professional training aligned to market needs.

Still in the use step, no studies are available with inputs for activity 12 (use and maintenance of hydro-sanitary equipment), which comprises sinks, toilets, faucets, etc., thus, representing an in-depth research opportunity in this area. Finally, in the deconstruction phase, encompassing activities 13 (abandonment and demolition, reuse and rehabilitation) and 14 (final disposal - transportation, recycling and discarding), no contributions from the literature were observed, representing a wide field for future research.

4. Conclusion

This study showed the importance of the construction industry for the world economy and the need for the Brazilian companies of this sector to adopt management methods to increase productivity, such as lean construction, respecting sustainability criteria.

Based on these findings, the present study attempted to address the research problem of how to integrate concepts of lean construction, sustainability and the life cycle of a building.

The research question was answered, achieving the main objective of the study, which was to develop a theoretical framework integrating concepts of lean construction, sustainability and the life cycle of a building, through a systematic review of the scientific literature, using the Scopus and SciELO scientific databases. The specific objectives were also achieved, detailing activities related to the production and consumption phases of the life cycle of a building, as well as the contributions of lean construction for sustainability in its economic, social and environmental dimensions.

The discussion indicates that there is still relatively little scientific literature on lean construction contributions for activities related to the use and deconstruction steps of the consumption phase of the life cycle of a building, representing vast opportunities for future research. Project activities, at the development step, and construction activity, at the step with the same name, were those with the highest number of lean construction contributions in the production phase of the life cycle.

The life cycle of hydro-sanitary equipment (sinks, toilets, faucets, etc.), which is part of the life cycle of any building, has been little explored so far. Likewise, it is important to conduct further research, involving the contribution of lean construction in the programming and planning of a building, to ensure an adequate life cycle, which meets environmental and design needs in order to satisfy customers, users and society in general.

Finally, to encourage companies of the construction industry sector to adopt lean construction, it is essential that lean construction concepts and tools are taught in technical schools and universities, to ensure trained professionals aligned to market needs.

Despite the contributions brought by this study, there are limitations in the research, primarily related to the keywords used in the applied search sentences, as well as the choice of the surveyed scientific bases, which led to the findings.

Even with these limitations, it is understood that this study provides a new way of organizing knowledge from the scientific literature, allowing viewing, in a same table, the integration and interrelationships of concepts about lean construction, sustainability and the life cycle of a building. The findings can contribute so that more companies adopt lean construction as a way to increase their productivity, as well as the productivity of the construction industry sector and of the country. This study is also useful for researchers who can explore several research lines from the results, developing new scientific papers.

References

Araujo, F.O.; Castro, F.P. (2012), “Proposal for OEE (overall equipment effectiveness) indicator deployment in a beverage plant”, Brazilian Association for Industrial Engineering and Operations Management (ABEPRO), Vol 9, No 1.

Arayici, Y. et al. (2011), “Technology adoption in the BIM implementation for lean architectural practice”, Automation in Construction, Vol. 20, pp. 189–195.

Associação Brasileira de Normas Técnicas – ABNT (2010), NBR ISO 26000, Diretrizes sobre responsabilidade social, Associação Brasileira de Normas Técnicas, Rio de Janeiro.

Bloom, N.; Reenen, J. V. (2010), “Why do management practices differ across firms and countries?”, Journal of Economic Perspectives, Vol. 24, No. 1, pp. 203-224, available at http://worldmanagementsurvey.org/wp-content/images/2010/07/Why-Do-Management-Practices-Differ-Across-Firms-and-Countries-Bloom-and-Van-Reenen.pdf. (Accessed on March, 2015).

Boggelen, W.M.V. (2011), “The contribution of AAC in securing a sustainable future. AAC innovations from a life cycle perspective”, Cement, Wapno, Beton.

Calcedo, J.G.S. et al. (2012), “Análisis comparativo en base a la sostenibilidad ambiental entre bóvedas de albañileria y estructuras de hormigón”, Revista Ingeniería de Construcción, Vol. 27, No. 1.

Confederação Nacional da Indústria - CNI (2013), Mapa estratégico da indústria 2013-2022, 2. Ed. Brasília: CNI, available at http://cni.org.br. (Accessed on March, 2015).

Díaz, V. A. O’R. et al. (2010), “Las tecnologías del concreto en su ciclo de vida”, Concreto y cemento, investigación y desarrollo, Vol. 1, No. 2.

Elkington, J. (1998), “Accounting for the triple bottom line”, Measuring Business Excellence, Vol. 2, No. 3, pp. 18-22.

Endo, L. M. A. et al. (2017), “Descriptive and comparative study of the purchasing activity: a case study in a food company”, Brazilian Journal of Operations & Production Management, Vol 14, No. 2, DOI: http://dx.doi.org/10.14488/BJOPM.2017.v14.n2.a14. (Accessed on July 31, 2017).

EY. (2014), Estudo sobre produtividade na construção civil: desafios e tendências no Brasil. São Paulo: EY, available at http://ey.com.br. (Accessed on March, 2015).

Federação das Indústrias do Estado do Rio de Janeiro - FIRJAN (2014), Construção Civil: Desafios 2020, Rio de Janeiro: FIRJAN, available at http://www.firjan.org.br. (Accessed on March, 2015).

Ferreira, W. et al. (2016), “Lean & Healthcare organizations – a systematic literature review with bibliometric analysis on application of lean healthcare in Brazil”, Brazilian Journal of Operations & Production Management, Vol 13, No. 4, DOI: http://dx.doi.org/10.14488/BJOPM.2016.v13.n4.a2. (Accessed on July 31, 2017).

Harper, C.; Hazleton, R. (2014), “New Engineer’s Knowledge for Success with Subcontractors and Trade Partners”, Practice Periodical on Structural Design and Construction, Vol. 19, No. 1, February 1.

Hidalgo Martins, G.; Cleto, M. G. (2016), “Value stream mapping and earned value analysis: a case study in the paper packaging industry in Brazil”, Brazilian Journal of Operations & Production Management, Vol 13, No. 3, DOI: http://dx.doi.org/10.14488/BJOPM.2016.v13.n3.a13. (Accessed on July 31, 2017).

Ibrahim, A. R. B. et al. (2010), “Analyzing the dynamics of the global construction industry: past, present and future”, Benchmarking: An International Journal, Vol. 17, No. 2, pp. 232-252.

Kalbusch, A.; Ghisi, E. (2012), “Método para quantificação do consumo energético no ciclo de vida de equipamentos hidrossanitários”, Ambiente Construído, Porto Alegre, Vol. 12, No. 3, pp. 57-73.

Koranda, C. et al. (2012), “An Investigation of the Applicability of Sustainability and Lean Concepts to Small Construction Projects”, KSCE Journal of Civil Engineering. Vol. 16, No. 5, pp. 699-707.

Martínez, P. et al. (2009), “Integración conceptual Green-Lean en el diseño, planificación y construcción de proyectos”, Revista Ingeniería de Construcción, Vol. 24, No. 1.

Martínez-Jurado, P. J. et Moyano-Fuentes, J. (2014), “Lean Management, Supply Chain Management and Sustainability: A Literature Review”, Journal of Cleaner Production, Vol. 85, pp. 134-150.

Martins, V. W. B. et al. (2016), “Problem-based learning method use in the civil construction organizational environment”, Brazilian Journal of Operations & Production Management, Vol 13, No. 1, DOI: http://dx.doi.org/10.14488/BJOPM.2016.v13.n1.a9. (Accessed on July 31, 2017).

Maruyama, Ú. et al. (2016), “Lean e-health care: its performance improvement based on Brazilian university case study”, Brazilian Journal of Operations & Production Management, Vol. 13, No. 4, DOI: http://dx.doi.org/10.14488/BJOPM.2016.v13.n4.a4. (Accessed on July 31, 2017).

Moher D. et al. (2009), “Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement”, PLoS Medicine, available at http://www.ncbi.nlm.nih.gov/pmc/articles/PMC2707599/. (Accessed on December 22, 2015).

Muñoz, C. et al. (2012), “Estudio del flujo energético en el ciclo de vida de una vivienda y su implicancia en las emisiones de gases de efecto invernadero, durante la fase de construcción. Caso Estudio: Vivienda Tipología Social. Región del Biobío, Chile”, Revista de la Construcción, Vol. 11, No. 3, pp. 125-145.

Nahmens, I. et Ikuma, L.H. (2012), „Effects of Lean Construction on Sustainability of Modular Homebuilding”, Journal of Architectural Engineering, Vol. 18, No. 2.

Nascimento, D. L. M. et al. (2016), “Project automation application with lean philosophy at the construction of oil refining unit”, Brazilian Journal of Operations & Production Management, Vol. 13, No. 1, DOI: http://dx.doi.org/10.14488/BJOPM.2016.v13.n1.a15. (Accessed on July 31, 2017).

Ogunbiyi, O. et al. (2014), “An empirical study of the impact of lean construction techniques on sustainable construction in the UK”, Construction Innovation, Vol. 14, No. 1. pp. 88-107.

Ortiz-Rodríguez, O. et al. (2012), “Environmental Impact of the Construction and Use of a House: Assessment of Building Materials and Electricity End-Uses in a Residential Area of the Province of Norte de Santander, Colombia”, Ingeniería Universidad Bogotá (Colombia), Vol. 16, No. 1, pp. 147-161.

Paim, R. et al. (2016), “Lean healthcare application in a surgical procedures appointment scheduling center in a maternity”, Brazilian Journal of Operations & Production Management, Vol. 13, No. 4, DOI: http://dx.doi.org/10.14488/BJOPM.2016.v13.n4.a5. (Accessed on July 31, 2017).

Passuello, A. C. B et al. (2014), “Aplicação da Avaliação do Ciclo de Vida na análise de impactos ambientais de materiais de construção inovadores: estudo de caso da pegada de carbono de clínqueres alternatives”, Ambiente Construído, Porto Alegre, Vol. 14, No. 4, pp. 7-20.

Pavez, I. et al. (2010), “Improving the Effectiveness of New Construction Management Philosophies using the Integral Theory”, Revista de la Construcción, Vol. 9, No. 1, pp. 26-38.

Robson, C. (2011), Real World Research: a resource for users of social research methods in applied settings. 3rd Ed. West Sussex: John Wiley & Sons, Ltd., chapter 5, pp. 81-129.

Salgado, M. S. et al. (2012), “Produção de edificações sustentáveis: desafios e alternativas”, Ambiente Construído, Porto Alegre, Vol. 12, No. 4, pp. 81-99.

Satolo, E. G. et al. (2012), “A multiple case study of sustainability issues in companies from sugar and ethanol industrial sector”, Brazilian Association for Industrial Engineering and Operations Management (ABEPRO), Vol. 9, No. 2.

Senna, P. et al. (2016), “Study on techniques and tools used in the lean healthcare implementation: a literature review”, Brazilian Journal of Operations & Production Management, Vol. 13, No. 4, DOI: http://dx.doi.org/10.14488/BJOPM.2016.v13.n4.a1. (Accessed on July 31, 2017).

Singleton JR., R. A.; Straits, B. C. (2010), Approaches Social Research. 5th Ed., Oxford University Press, Inc., chapter 12, pp. 393-430.

Treinta, F. T. et al. (2014), “Metodologia de pesquisa bibliográfica com a utilização de método multicritério de apoio à decisão”, Production, Vol. 24, No. 3., available at http://dx.doi.org/10.1590/S0103-65132013005000078. Print version ISSN 0103-6513. (Accessed on March, 2015).

Tykkä, S. et al. (2010), “Development of timber framed firms in the construction sector — Is EU policy one source of their innovation?”, Forest Policy and Economics, Vol. 12, pp. 199–206.

Vanalle, R. M. et al. (2009), “Strategies of production in the automobile industry: a multi-case study in Spain and Brazil”, Brazilian Association for Industrial Engineering and Operations Management (ABEPRO), Vol. 6, No. 2. (Accessed on July 31, 2017).

Wilber, K. (2001), “A Theory of Everything: An Integral Vision for Business, Politics, Science and Spirituality”, Shambala Publications, Boston, USA, 189 pp.

Wilber, K. (2005), “The Integral Vision of Healing”, in Schlitz M, Amorok T, Micozzi MS, editors. Consciousness and healing: integral approaches to mind-body medicine. Elsevier/Churchill Livingston, St Louis, USA.

Wilber, K. (2007), “The Integral Vision: A Very Short Introduction to the Revolutionary Integral Approach to Life, God, the Universe, and Everything”, Shambala Publications, Boston, USA, 224 pp.