Parameters involved in the internal reverse logistics of a hospital pharmacy

Kao Pei Yui1, Camila Candida Compagnoni dos Reis2, Matheus Fernando Moro2, Sandrine de Almeida Flores2, Adriana Yolanda Morales Garza2, Neron Alípio Cortes Berghauser1, Andreas Dittmar Weise2

1 Federal Technological University of Paraná; 2 Federal University of Santa Maria

Abstract

This research aims to identify the causes linked to internal reverse logistics of materials and medicines in a hospital, covering studies for process optimization performed by this department. The study is based on a hospital located in the State of Paraná, Brazil. First, observations were performed through visits during the months of September/2015 to April/2016, and the month of March was chosen for the collection of data. Also, "in loco" visits were carried out for better understanding the process that occurs in both of the drug shipment to patients, as the internal reverse logistics was performed with drugs. To collect the data a survey form was used on the main reasons for discarding of drugs and materials for the central pharmacy. The instrument was adapted from the form used by the institution aimed specifically to the Intensive Care Unit. Through the observations made in the Hospital Unit, it was revealed that the company has a structured logistics process, standardized, and has a fundamental tool for this: information technology, creating efficient, reliable and fast data, requiring however, some improvements aiming primarily to prevent and reduce waste of both time and materials/medicines.

Keywords: Reverse Logistics; Optimization; Hospital Pharmacy.

1 Introduction

The health sector is presented as extremely important for the development of Brazil (Dallora et Foster, 2013). In order to have an idea of its representation in the economic scenario, in 2011 the financial transactions of this sector were nearly 9% of the gross domestic product - GDP, about 20 billion reais, employing about 12 million formal workers (Brasil, 2011). Given its representation and socio-economic importance, the sectors are showing an increasing demand for resources due to the high technology involved in it, associated to insufficient resources in the public sector, which justifies, according to Bonacim et Araujo (2010), the need for studies and practices in this area.

Considering countries with universal health system, Brazil is the one with the lowest percentage of investment in terms of GDP – 4% against an investment of 4.9% in Argentina, 7.7% in the United Kingdom and 7.8% in Canada (Brasil, 2014). Parallel to low investment, recent problems of funding reduction for public health (Louise, 2015) has impacted the sector, resulting in a concern regarding the scope and quality of the services offered by the Unified Health System (SUS- Sistema Único de Saúde).

Regarding hospitals, specifically, they are meant to serve and assist people in order to promote health, involving complete medical, preventive, therapeutic and healing assistance (Araújo et al. (2012), in such a way that they assume part of the responsibility of costs and quality of the entire health system (Porter et Teisberg (2007). Hospitals represent a type of organization with a structure considered complex, including a variety of professionals and advanced technological resources, conciliating entrepreneurial interests, without distancing themselves from their own ethical and legal principles (Lemos et Rocha, 2011).

Hospital buildings operate 24 hours a day, seven days a week, 365 days a year, thus making them major consumers of resources (Zioni, 2015). Therefore, coexisting situation with the use of high technology for diagnosis and treatments, as well as high waste rates (Contreras Pinochet et al., 2014) tend to increase the operating costs of these facilities. Vogl (2014) claims that over 90% of costs in hospitals in Germany are considered operating costs, which confirms, as advocated by Bonacim et Araujo (2010) and Dallora et Forster (2013) the need to intensify research in order to reduce them.

In this manner, the operations management in hospitals is presented as essential and of unique character (Araújo et al., 2012). Corroborating, Souza et al. (2013), highlighting the logistical challenge in these environments, where organizational needs must be met in a quick, correct and efficient way, since they relate not only with the costs involved, but also with the quality of health assistance provided to the users. With regard to logistics costs, a survey conducted in the US showed that on average 35% of total spending in a hospital refers to the purchase of materials and services (Minham, 2007). In this sense, Oliveira et Musetti (2014) advocate that flaws in the distribution of medication and materials, for example, could result in irreparable disasters for both the hospital and the patient.

The involvement of different sectors and areas in hospitals, according to Pereira (2006), must present a harmonious relationship so that greater efficiency in terms of the services provided can be achieved. In general, they can be segmented in areas intended for patient assistance (as ambulatory, emergency department, inpatient units, operating rooms, etc.), and support areas, which provide assistance for the operation of the entire organization (Souza et al., 2013). Support areas can be divided, as Gonçalves et Ache (1999) present in: (a) administrative support involving financial, materials, human resources and systems management, besides warehouse and pharmacy; (b) logistical support involving laundry, materials sterilization center, maintenance, janitorial service, security, and cleaning; and (c) technical support, which includes nursing services, medical services (diagnosis and treatment), nutritional and dietetic services, physiotherapy and psychology services.

The importance of another factor for these areas to communicate effectively is noted: the Information Technology (IT). According to Taraboulsi (2009) IT should be understood as a technology portfolio that automates procedures, routines, and processes of human labor in productive and administrative levels. Technology is essential in the health sector and can often be a fine line between survival and fatality (Santos, 2006). In addition, IT in healthcare institutions provides an enhancement of the treatment processes, propagation and transfer of information, adding value to services and turning decision making more agile, effective and consistent (Tarabolusi, 2009).

As this research approaches the study of internal reverse logistics of materials and medications in hospitals, for its development the administrative support area was considered, specifically the hospital pharmacy. According to the Brazilian Agency for Industrial Development (ABDI - Agência Brasileira de Desenvolvimento Industrial, 2013), hospitals constitute an important link in dispensing medication to the population. Therefore, the aspect of some hospital pharmacies should be understood as follows.

The management of a pharmacy or hospital warehouse is something of great importance, as they are sectors which keep the most expensive inputs: medicines and hospital supplies. The Brazilian Society of Hospital Pharmacy – (SBRAFH - Sociedade Brasileira de Farmácia Hospitalar, 2007) defines hospital pharmacy as a unit of clinical and healthcare nature, with administrative and managerial capacity, being one of the most important sectors in the hospital context.

Among its essential functions are storage, distribution, dispensing and control of all the medicines and health products for inpatient and outpatient of the hospital, as well as the fractionation and preparation of medications (SBRAFH (2007). According to the Basic Guide for the Hospital Pharmacy of the Ministry of Health (1994), a hospital pharmacy must be located in an area of free access and movement, in order to meet the distribution of medication to patients, as well as to receive other pharmaceuticals purchased for consumption.

It can be stated that there are five fundamental pillars for the hospital pharmacy sustainability: (a) selection of medications, germicides and related; (b) acquisition, conservation and control of selected medications; (c) handling/production of medication, germicides-Pharmacotechniques; (d) establishment of a medications rational distribution system; and (e) implementation of medication information system (Ministério da Saúde, 1994). The SBRAFH (2007) states that implementation of a rational distribution system should be prioritized by the pharmacist and by the institution in order to seek processes that promote greater safety for patients.

Once removed from the hospital pharmacy, reverse logistics proceeds to respond about the medications. As stated by Melo et Scapini (2016) the definition for Reverse Logistics involves the continuation of products’ cycle, so that it does not end in the consumer. In the case of the present study, only the internal reverse logistics of medications or materials is involved in the causes by which they return to the hospital pharmacy or are sent to disposal. Once opened, most of the medicines cannot return to storage, so they should be discarded, which, in case of wrong procedures, can generate waste not only of the product in matter, but also of the preparation time of a new dose and materials used.

Given the above, this research aims to identify the causes linked to internal reverse logistics of materials and medications in a hospital, covering studies for the optimization of the process performed by this sector. A good integrated management in this sector may result not only in reducing losses, but also in a greater efficiency in terms of the quality of services provided by the hospital pharmacy unit.

For better understanding of the undertaken activities, after the introductory section, the addressed methodology is presented, covering the identification of the object of study and developed steps. Following, achieved results are presented, in order that the reader can identify the information gathered in the study case, as well as some relevant considerations. Finally, relevant conclusions consistent with the objective and some suggestions for future research are discussed.

2 Methodology

The research is based on a hospital located in the Western Region of the State of Paraná, Brazil, founded in 1979, being the first hospital in Paraná to be certified by the National Accreditation Organization (ONA- Organização Nacional de Acreditação), it counts with the quality seal, level I and II, proving that it has security, standardization of procedures, training programs and quality of services. It is classified as a General Hospital of large scale, with over 300 beds in 16,000 square meters of built physical area, offering everything from emergency assistance to high complexity services. The hospital is considered as regional reference in cancer treatment, cardiology and high-risk pregnancy.

The pharmaceutical service counts with five pharmaceutical professionals, 11 administrative auxiliaries and 23 pharmacy auxiliaries, which act in four pharmacies that the hospital owns, being three satellite pharmacies: Intensive Care Unit (ICU), Surgical Center and Emergency Department and the Central Pharmacy, object of study of this research.

The dispensing system of the pharmacy under study is classified as individualized centralized, characterized by dispensing materials and medications per patient in three shifts, and having the central pharmacy to distribute them. The central pharmacy is strategically centered between the hospital blocks, facilitating the dispensing flow. It provides for six different blocks, divided into: UTI (general, coronary and neonatal), Block 2: SUS (oncology), Block 6: private and covenant, Block 7: maternity, Block 8: covenant and particular, Block 10: SUS (general clinic).

In the search for resolution of the proposed objective observations were made by conducting visits during the months of September of 2015 to April of 2016, being March the month used for data collection. For the present study, on-site visits were carried out in order to understand the process that occurs in both the delivery of medication to the patient, and the internal reverse logistics carried out with medications.

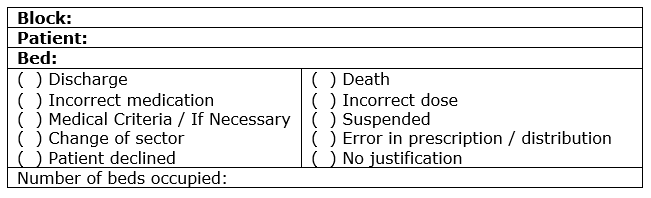

For the collection of data, a form with the main reasons for the return of medication and materials to the central pharmacy was implemented. The instrument was adapted from a form used by the institution designed specifically for the ICU and is shown in Figure 1.

Figure 1. Form of causes for return of medication and materials

Source: The author

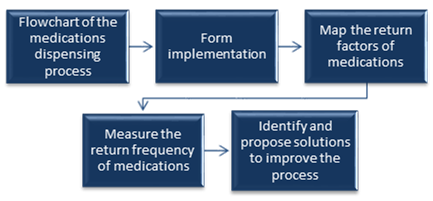

Data was collected only from Blocks 6 and 8, because authorization for this research was obtained only for those two sectors. It was systematically stipulated that on Mondays, Wednesdays and Fridays, data would be collected from materials and medications returned from the night shift and on Tuesdays and Thursdays it would be from the morning shift inputs. For an objective view, the steps of the research are presented in Figure 2. The study began performing on-site observations.

Figure 2. Research steps

Source: The author

Through the collected observations, a flowchart of the medication dispensing process was elaborated. The data obtained from the forms was tabulated and then graphed in order to help clarify and emphasize the mass of data, thus being able to understand and visualize relevant aspects. In this way, the frequency with which medications were returned could be measured and the causes that led to it could be identified. Finally, it was intended to identify and propose solutions for improvements in the process.

3 Results and discussion

From the on-site observations made and the applied forms during the months of research, the following results, related to the study’s objectives, are presented.

3.1 Processes description

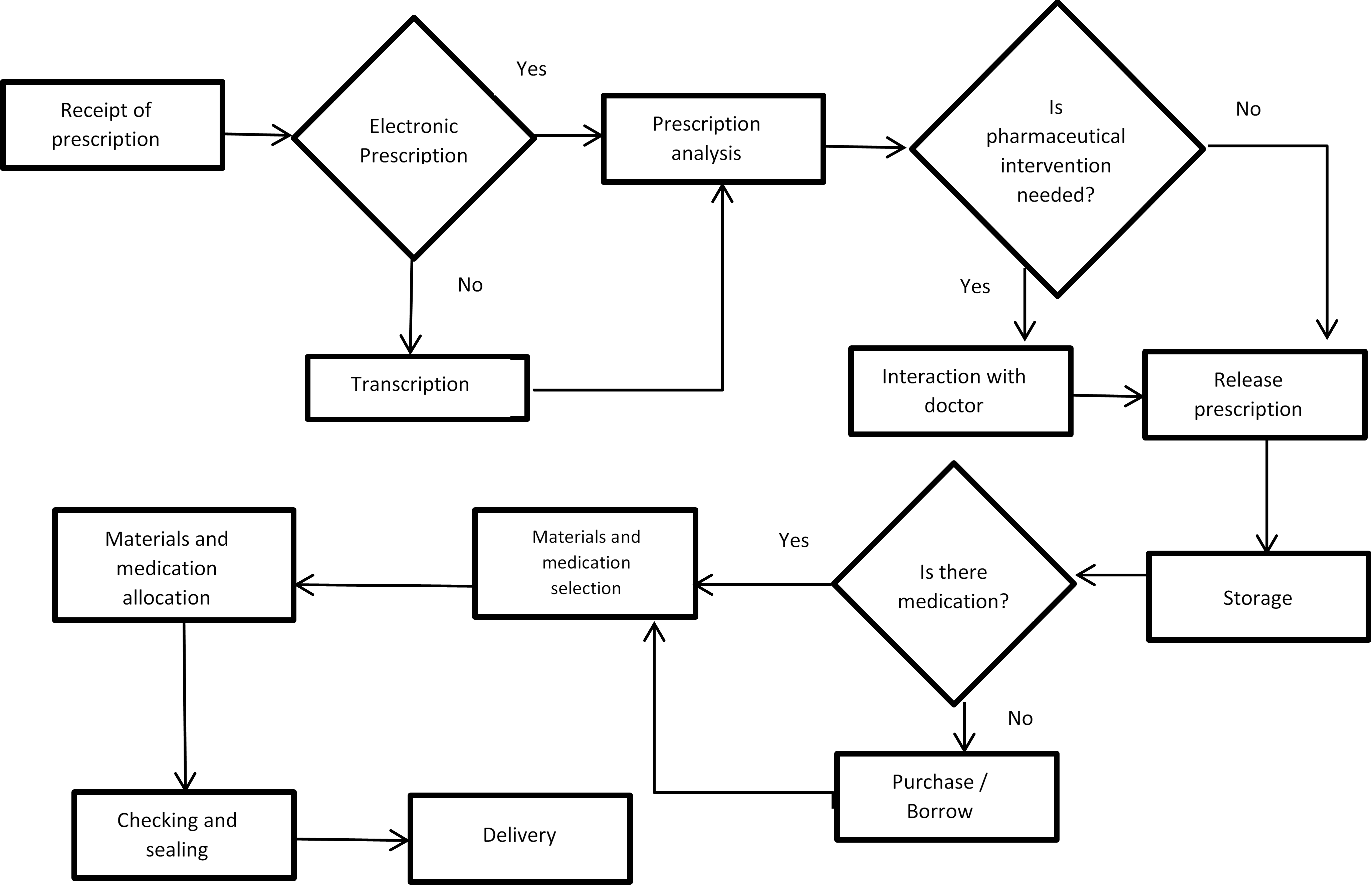

Through observations, it was possible to understand the expedition process of pharmaceutical inputs and elaborate the flowchart of this process, shown in Figure 3.

Figure 3. Flowchart of the process of pharmaceutical inputs supply to hospital beds

Source: The author

The process begins with the receipt of the medical prescription, if it is electronic it is printed, otherwise it is transcribed. The need for pharmaceutical intervention is verified and after this, the prescription is released. The pharmacy’s employee, who has the medical prescription recipe, takes each product on the pharmacy’s shelf and deposits them in a plastic tray; if the pharmacy is out of the required input, then it is borrowed from another hospital or a purchase is effectuated. After all the required medication is on the tray, they are removed from the system and entered in the patient's account, with the aid of a bar code scanner. After the removal of the inputs from the system, materials and medications are separated by schedules and disposed in a tray properly identified, then, they are taken to a sealing machine, which individually package the required inputs.

As drugs are being individually packaged, they are identified with self-adhesive labels with information such: patient’s name, bed number, medication’s name, time to be administered and responsible doctor. Finally, these products are taken to each block by means of carts, in case the medication is for urgent use, it is disposed in a basket labeled “NOW” in order to be distributed to the appropriate patients.

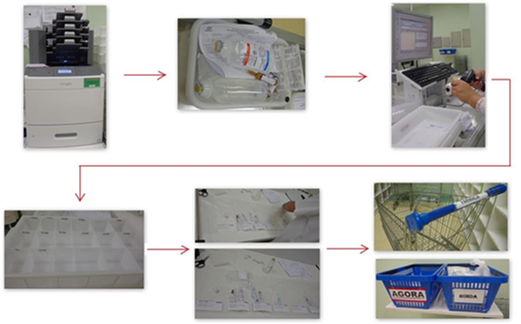

The software used in the organization has a specific algorithm to prevent non prescribed medications and materials to be brought to the patient; it even prevents them from being mistakenly downloaded from the system, so as the wrong amount. For better understanding it was elaborated a schematic illustration shown in Figure 4.

Figure 4. Illustration of the dispensing process of pharmaceutical inputs

Source: The author

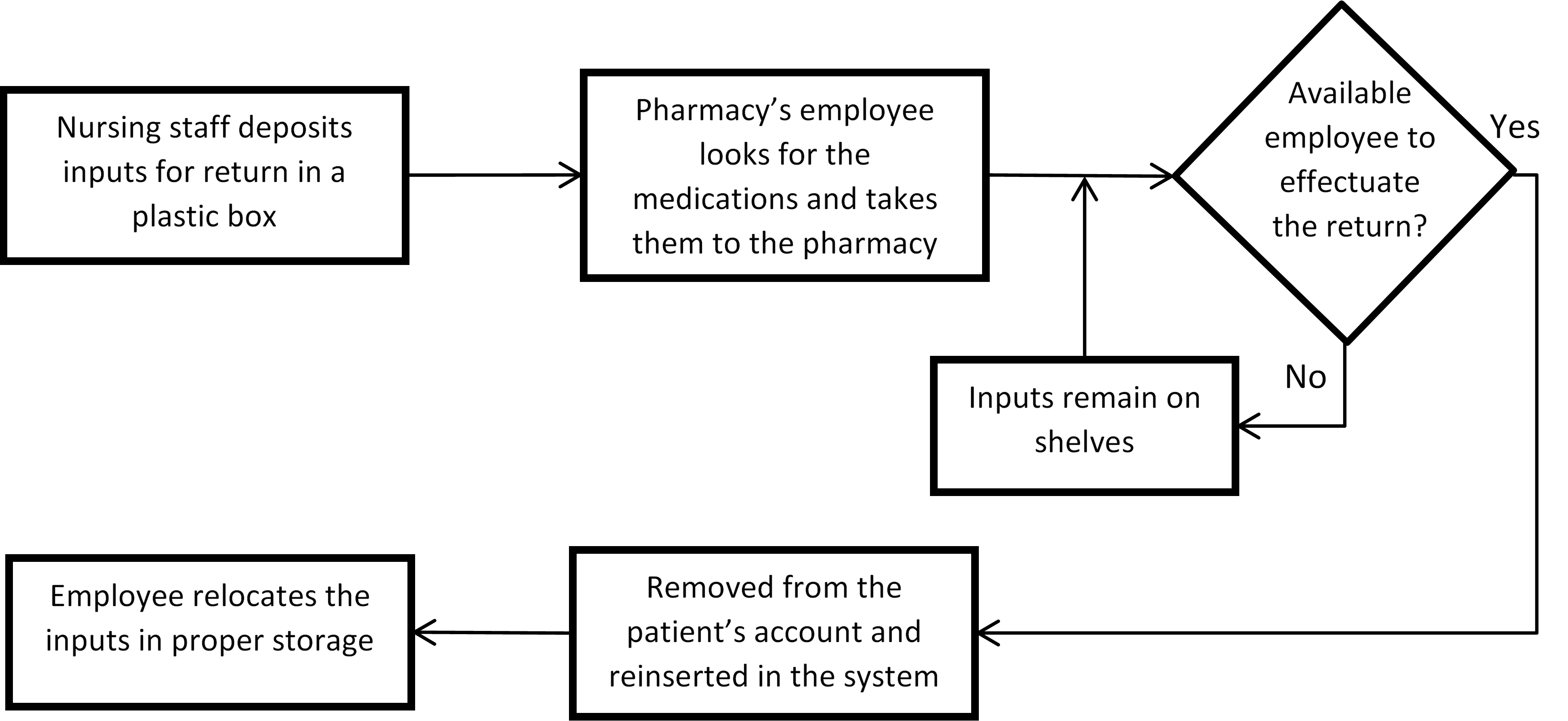

For the process of the return of pharmaceutical inputs from the blocks to the central pharmacy, a flowchart is presented in Figure 5.

Figure 5. Flowchart of the return of materials and drugs to the hospital pharmacy

Source: The author

Reverse logistics of pharmaceutical inputs begins in hospital blocks with the inputs being deposited in plastic boxes labeled as “Medication Return”. In varying and non-specific intervals, the central pharmacy employees go through the different blocks and with the aid of a shopping cart collect the medications that are temporarily stored in the shelf and are reinserted into the system. At the end of the reverse logistics process, the medications are relocated in the proper storage. Figure 6 sequentially illustrates the return process of materials and medications.

Figure 6. Illustration of the return of materials and pharmaceutical medication process

Fonte: The author

3.2 Factors linked to the return of medications and materials

It is necessary to identify the reasons that cause the internal reverse logistics of materials and medications. These losses are activities completely unnecessary, which generate cost, do not add value and, therefore, must be immediately eliminated.

The hospital in matter develops mapping practices of the main reasons for the return of medications occurred only in the ICU sector. For these practices, a form is used, which must be completed by the nursing staff from this sector, immediately after the process occurs. In this way, more accurate records of the causes of medication return in this sector are obtained. In order to fill the form with the causes of return of medication, the form provides the following factors: (a) Patient discharge; (b) Death; (c) Under Medical Criteria / If necessary; (d) Incorrect medication; (e) Incorrect dose of medication; and (f) Medication suspended by medical orders.

Blocks 6 and 8, which received authorization for this research, count with medical assistance designated for a private convention. Therefore, new arguments for the return of medications, which were not in the form used in the ICU, were identified. The direct contact with the nursing staff in Blocks 6 and 8 allowed researchers to insert additional return factors, as follows: (a) Change of patient’s sector (due to emergencies, exams, or surgery); (b) Error in prescription / distribution; (c) Patient declined; and (d) No justification identified. With the addition of these four items, the list increased to ten justifications for the return of inputs to the central pharmacy. The resulting analysis of the justifications for medication return in Blocks 6 and 8 are discussed in the following sections.

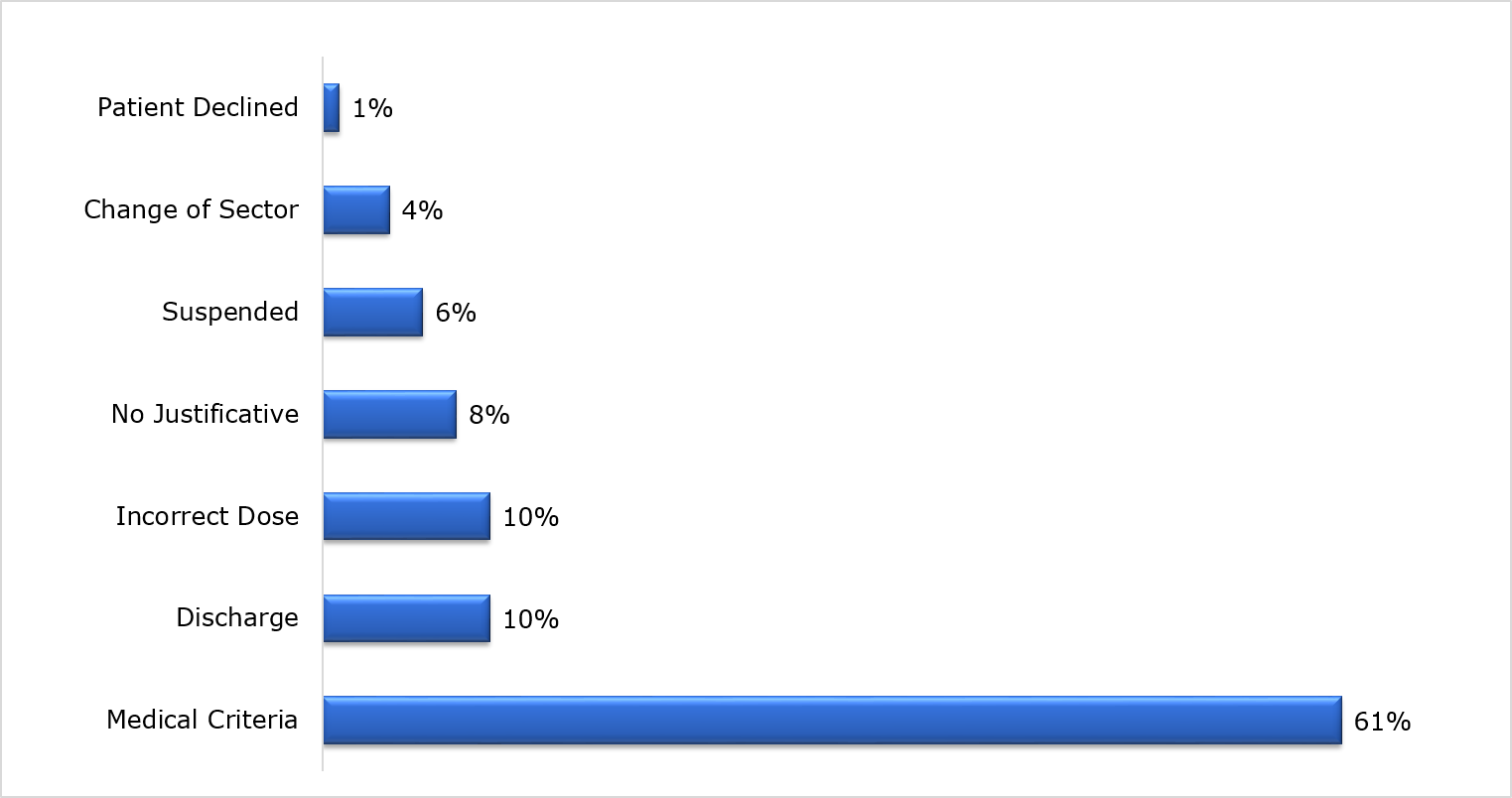

3.2.1 Analysis of the return of inputs in Block 6

In Block 6, the relation between the causes of materials and medication return and the percentage of occurrence of the period studied is detailed in Figure 7. It is important to mention that, during this period, 149 returns were observed.

Figure 7. Causes for return of inputs in Block 6

Source: The author

Of the ten reasons, three of them have not been verified, they are: (I) Death; (II) Incorrect Medication; and (III) Error in prescription / distribution. It is noted that the main cause for returns in Block 6 was “Upon Medical Criteria / if necessary”. These causes represent 61% of the returns occurred in a month. Patient discharge and incorrect dose obtained 10% returns each. These three causes represent 81% of returns during the month. It should be noted that this block has capacity of 30 beds and the occupancy average for the month of March was 22 beds / day.

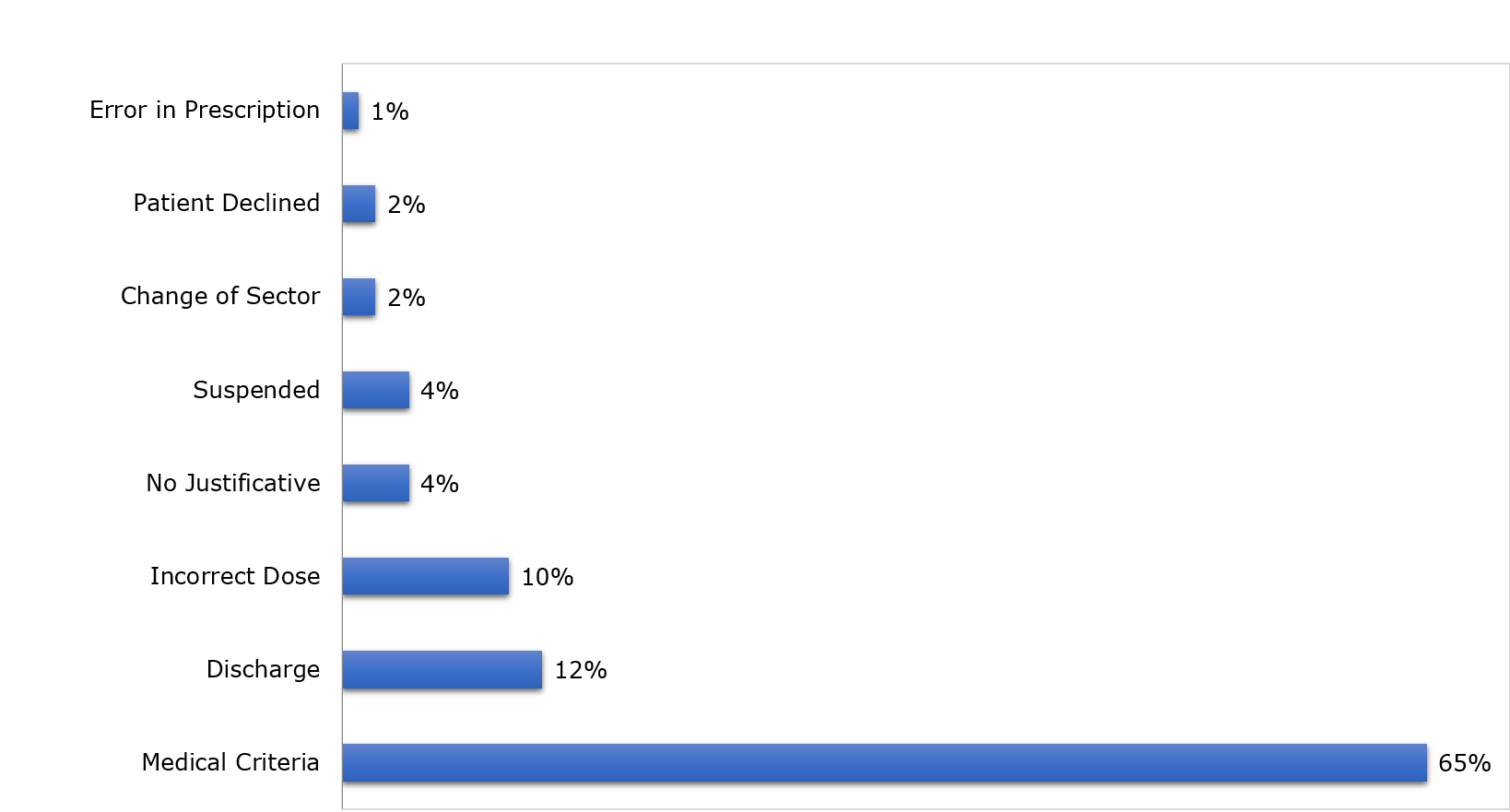

3.2.2 Analysis of the return of inputs in Block 8

The percentage of occurrence of returns in Block 8, and the causes thereof, are presented in Figure 8. During the study period 93 returns we observed.

Figure 8. Causes for return of inputs in Block 8

Source: The author

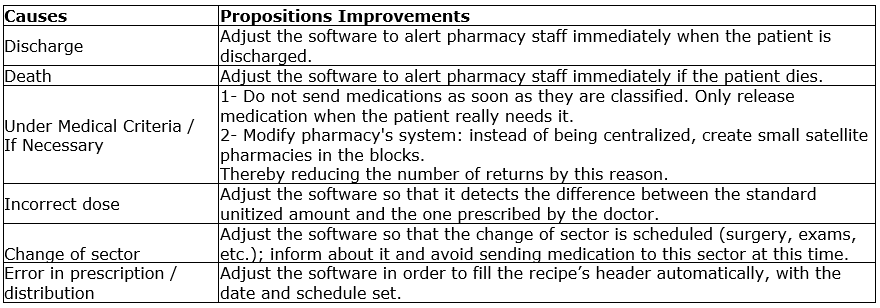

3.3 Suggestions for improvements

Based on the results of the research presented in the previous section, opportunities to leverage the performance of the hospital pharmacy from the point of view of returns of inputs were identified and are presented in Figure 9.

Figure 9. Proposed improvements to minimize input returns

Source: The author

For the reasons of discharge, death and change of sector an adjustment in the software is proposed in order to inform immediately the patient’s situation. This can be achieved by means of a panel (window) that displays the patients that suffered one of these situations; a beep to draw attention to a particular patient or; the use of colors to alert the pharmacy staff.

According to perception during the process, incorrect dose occurs most often with ointments and not so stable liquid medications that are delivered in the original presentation. If the doctor prescribes these types of medications in smaller doses than their laboratory presentations and/or more than once a day, they are delivered to the patient as many units of medications prescribed by the doctor, without calculating, for example, that only one of these bottles could be used by patient during the prescription period (day). The proposition for this situation is to create a virtual database, on the software used in pharmacy, of medications whose presentation is in liquid form or ointment with their respective volumes, so that it appears on the patient’s prescription and he can calculate how many bottles of medication exactly are being required.

Error in prescription / distribution process occurred only once with the date informed on the medical prescription’s heading. As an improvement proposal for this point, it is suggested this heading to be automatically filled and fixed by the system and, not allowing the user to make any changes.

Due to the significant number of returns of materials and medicines under “Medical Criteria / if necessary”, the first exposed suggestion is not to send these materials right after they are classified, since these are optional inputs in the patient’s treatment. The delivery should be effectuated only when required and if the patient chooses to use it. The pharmacy operates 24 hours, so there is always availability to supply the requirements. The second option involves the installation of satellite pharmacies on every block or certain blocks. This suggestion would possibly end with the occurring returns; it should be considered that at least five employees would be needed for each satellite pharmacy and that the maximum capacity that a block of this hospital has is 36 beds.

4 Conclusions

Through the observations made in the Hospital Unit it was possible to notice that the company present a structured and standardized logistics process, and counts with a fundamental tool for this: information technology, generating efficient, reliable and fast data. The mapping of new indicators for returns was possible thanks to the daily contact with the nursing staff at the place where the returns occur.

Quantitatively measuring the justifications for returns and presenting the data in graphics helped to clarify and highlight the main cause involved in the reverse logistics. In this study, the inputs returned due to the cause of “Medical Criteria” were responsible for over 60% of returns, both for Block 6 as for Block 8. An interesting finding, since these drugs are prescribed by doctors, if there is a need to use by the patient, or optional inputs that generate a significant number of returns. Still, according to the data entry, most of these medications are usual (do not present contraindication) and in lower incidence they are 'black box medications'.

The following improvements were proposed: adjustments in the software used by the pharmacy to alert the patient's condition, not sending inputs classified as “Medical Criteria” directly, installation of satellite pharmacies in certain blocks and creation of an input database, which presents the medication in liquid and ointment form, in order to calculate the required amount correctly and avoid that returns caused by an incorrect dose occur.

The proposed objective was achieved through demonstrated results and through the analysis of this important issue which is the reverse logistics of medications in hospitals. Due to the relevance of the topic, research on this subject should be carried out in order to seek knowledge in cost reduction within the hospital management. It is suggested, as a continuation of the research: (a) the economic feasibility study of the installation of satellite pharmacies in each hospital block; (b) economic feasibility study of the software adjustment; and also (c) the economic feasibility study for the acquisition of new software that meets more effectively the needs of the establishment.

The improvements proposed in this research do not only fit the hospital under study but also different health establishments. The optimization of the medications and materials dispensing process reflects in lower operating costs and greater efficiency and quality of the services provided, being presented as a strategic tool in operations management.

References

Agência Brasileira de Desenvolvimento Industrial (2016), “Logística Reversa para o setor de medicamentos”, available at: http://portal.anvisa.gov.br/wps/wcm/connect/6035fe804362f6fbaca0be0eb77d2a7a/Log%C3%ADstica+Reversa+de+Medicamentos.pdf?MOD=AJPERES (Acessed on 15 May 2016).

Araújo, E. A., Araújo, A. C. and Musetti, M. A. (2012), “Estágios organizacionais da logística: estudo de caso em organização hospitalar filantrópica”, Produção, Vol.22 No.3, pp. 549-563.

Bonacim, C. A. G. et Araujo, A. M. P. (2010), “Gestão de custos aplicada a hospitais universitários públicos: a experiência do Hospital das Clínicas da Faculdade de Medicina de Ribeirão Preto da USP”, Revista de Administração Pública, Vol.44 No. 4, pp. 903–931.

Brasil (2011), Portal Brasil, Economia e Emprego. Brasília, available at http://www.brasil.gov.br/economia-e-emprego/2011/05/alexandre-padilha-destaca-papel-da-saude-na-economia-brasileira (Acessed on 18 January 2016).

Brasil (2014), Senado Federal, Em Discussão: Revista de audiências públicas do senado federal. Brasília, available at http://www.senado.gov.br/noticias/jornal/emdiscussao/Upload/201401%20-%20fevereiro/pdf/em%20discuss%C3%A3o!_fevereiro_2014_internet.pdf (Acessed on 20 January 2016).

Contretas Pinochet, L. H., Lopes, A. D. S. and Silva, J. S. (2014), “Inovações e Tendências Aplicadas nas Tecnologias de Informação e Comunicação na Gestão da Saúde”, Revista de Gestão em Sistemas de Saúde, Vol.03 No.02, pp. 11–29.

Dallora, M. E. L. D. V. et Forster, A. C. (2013), “Gerenciamento de custos de material de consumo em um hospital de ensino”, Revista Administração em Saúde, Vol.15 No.59, pp. 46–52.

Gonçalves, E.L. et Aché, C.A. (1999), “O hospital-empresa: do planejamento à conquista do mercado”, Revista de Administração de empresas, Vol.39 No.1, pp. 84-97, available at http://www.scielo.br/pdf/rae/v39n1/v39n1a09.pdf (Acessed on 25 January 2016).

Lemos, V. M. F. et Rocha, M. H. P. (2011), “A Gestão das Organizações Hospitalares e suas complexidades”, paper presented at CNEG 2011: Congresso Nacional de Excelência em Gestão, Niterói, RJ, 12-13 August 2011, available at http://www.inovarse.org/node/2811 (Acessed on 12 April 2016).

Louise, A. (2015), “Em 2016, Ministério da Saúde reduzirá gasto com SUS em quase R$10 bilhões”, available on http://www.hojeemdia.com.br/horizontes/em-2016-ministerio-da-saude-reduzira-gasto-com-o-sus-em-quase-r-10-bilh-es-1.367603 (Acessed on 20 January 2016).

Mello, M. F. et Scapini, R. (2016), “Reverse Logistics of agrochemical pesticide packaging and the impacts to the environmental”, Brazilian Journal of Operations & Production Management, Vol.13 No.1, pp. 110-117.

Minaham, T. (2007), “Can supply management technology be the antidote to the healthcare crisis”, Health Management Technology, Vol.28 No.9, pp. 52-55.

Ministério da Saúde (1994), Coordenação de controle de Infecção Hospitalar, “Guia Básico para a Farmácia Hospitalar”, Brasília, available at http://bvsms.saude.gov.br/bvs/publicacoes/partes/guia_farmacia1.pdf (Acessed on 26 January 2016).

Oliveira, T. S. et Musetti, M. A. (2014), “Revisão compreensiva de logística hospitalar: conceitos e atividades”, Revista de Gestão em Sistemas de Saúde, Vol.3 No.1, pp.1-13.

Pereira, M. (2006), Um Modelo de Gestão de Abastecimento de Medicamentos em Farmácia Hospitalar, Tese de Doutorado em Engenharia de Produção, Universidade Metodista de Piracicaba, Santa Bárbara D’Oeste, SP.

Porter, M. E., et Teisberg, E. O. (2007), Repensando a saúde: estratégias para melhorar a qualidade e reduzir os custos, 1 ed., Bookman, Porto Alegre, RS.

Santos, G. A. A. (2006), Gestão de Farmácia Hospitalar, Senac, São Paulo, SP. Sociedade Brasileira de Farmácia Hospitalar – SBRAFH (2007), Padrões mínimos para farmácia hospitalar e serviços de saúde, Goiânia: SBRAFH.

Souza, A. A., Pereira, A. C. C., Xavier, A. G., Xavier, D. O. and Mendes, E. S. (2013), Logística Hospitalar: um estudo de caso diagnóstico das dificuldades na gestão logística de setor de engenharia clínica. Revista Eletrônica de Administração, Vol.12, No.1, pp. 1-14.

Tarabolusi, F. A. (2009), Administração de hotelaria hospitalar, 4 ed., Atlas, São Paulo, SP. Vogl, M. (2014), “Hospital financing: calculating inpatient capital costs in Germany with a comparative view on operating costs and the English costing scheme”, Health policy, Vol.115 No.2-3, pp. 141–51, available on http://www.healthpolicyjrnl.com/article/S0168-8510%2814%2900026-8/pdf (Acessed on 24 January 2016).

Zioni, E. (2015), “A importância da água nas edificações de assistência à saúde”, available on http://blog.gbcbrasil.org.br/?p=689 (Acessed on 17 January 2016).